job plan display system

A technology of operation planning and display system, applied in general control systems, control/regulation systems, computer control, etc., can solve problems such as system load increase, suppress the increase in system load, improve operability or work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

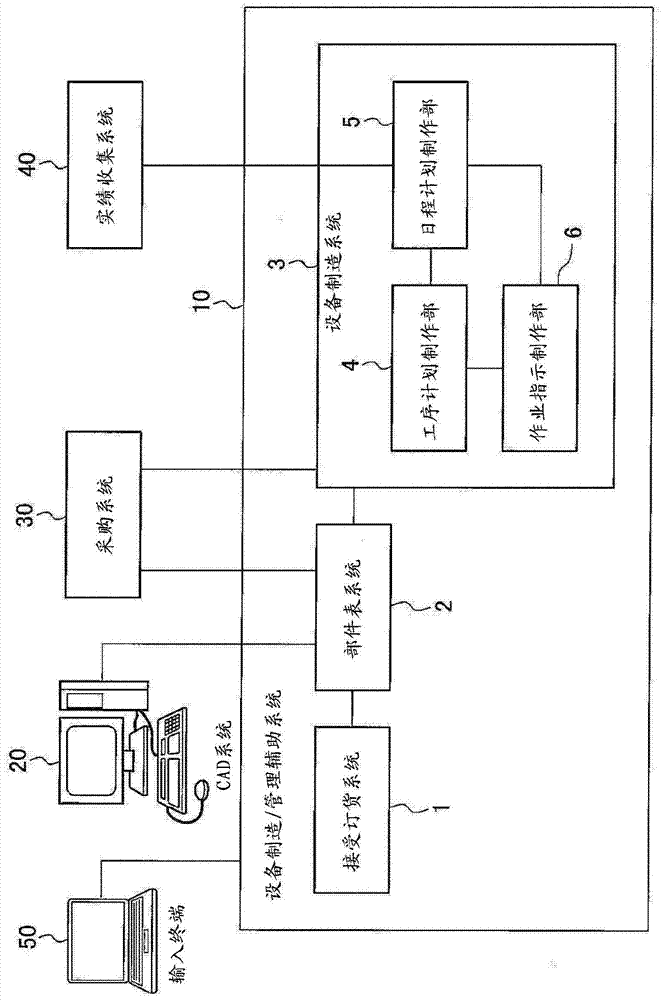

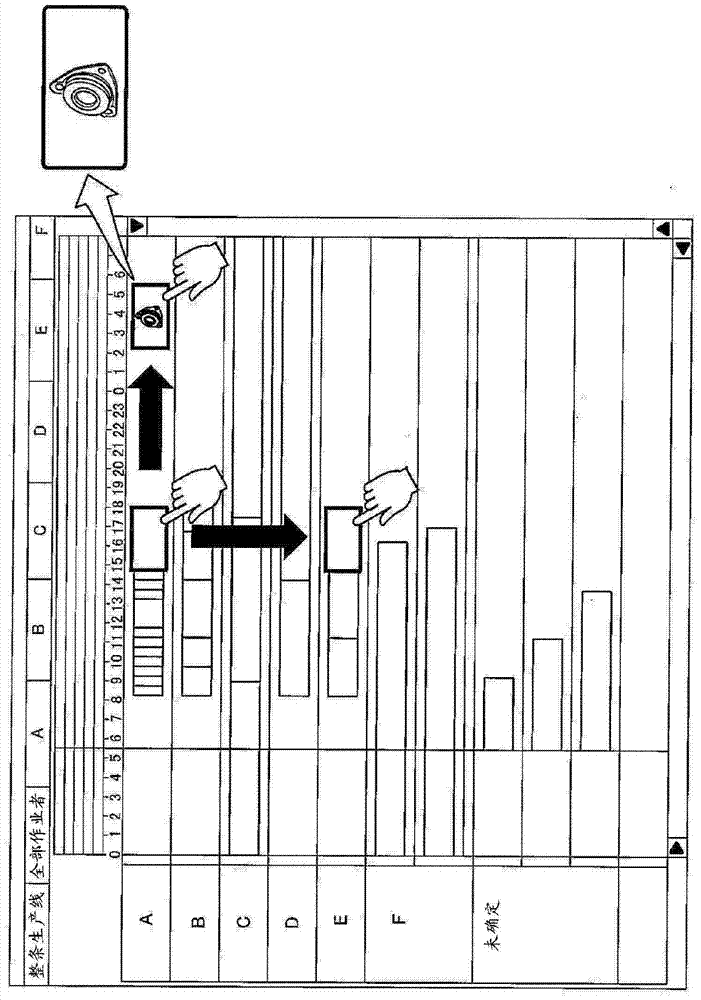

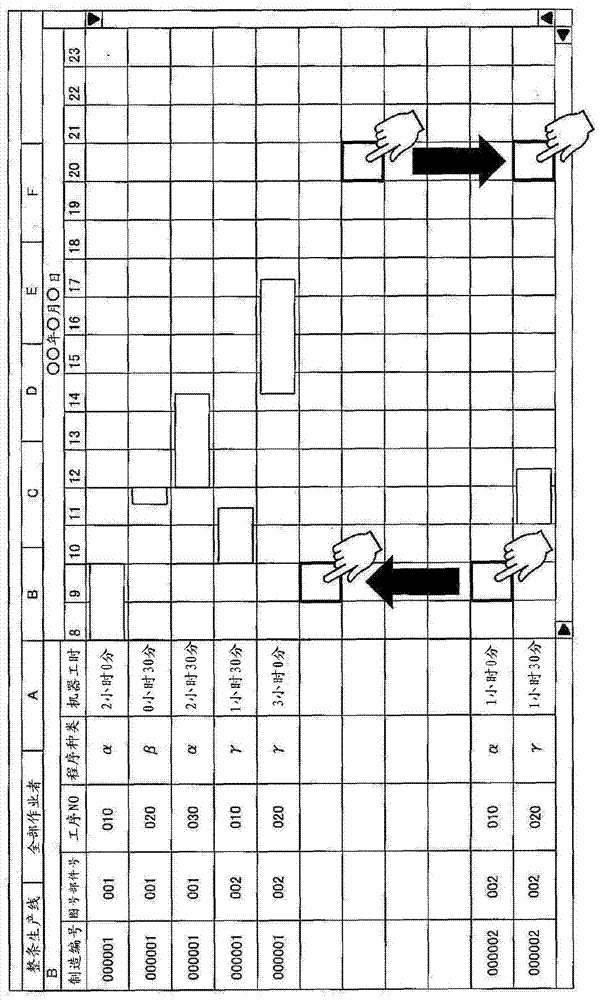

[0030] figure 1 It is a basic configuration diagram showing the basic configuration of the facility manufacturing / management support system according to the first embodiment to which the work plan display system of the present invention is applied. Here, the equipment manufacturing / management support system 10, for example, cooperates with the CAD system 20, the procurement system 30, and the performance collection system 40, etc., in which the CAD system 20 assists in the production of equipment and machinery, and the management of production. , the design data (CAD data) of the machine or its constituent parts, the procurement system 30 creates procurement data on the order and purchase of materials and parts to be used, and the performance collection system 40 summarizes the start, completion, Actual performance data about the work, such as the required work time and the operator in charge of the work. In addition, the facility manufacturing / management support system 10 is...

Embodiment approach 2

[0046] Figure 5 It is a flowchart explaining the flow of display processing performed by the second embodiment of the work plan display system (schedule creation unit 5 ) of the present invention. In this second embodiment, instead of the intention of the designer who created the CAD data, it is determined based on the preset update time whether to display or update the thumbnails in the "job bar". same. Therefore, the same reference numerals are assigned to the same components as those in Embodiment 1, and detailed description thereof will be omitted.

[0047] like Figure 5 As shown, the schedule preparation unit 5 of the second embodiment first creates an operation plan for each numerically controlled machine tool based on information transmitted from the parts list system 2, the procurement system 30, the performance collection system 40, etc., as in the above-mentioned first embodiment ( STEP 100), this operation plan is constituted by a plurality of unit operations, ...

Embodiment approach 3

[0054] Image 6 It is a basic configuration diagram showing the basic configuration of an equipment manufacturing / management support system according to Embodiment 3 of the work plan display system (schedule creation unit 5) of the present invention, Figure 7 is explained by Image 6 The flow chart of the flow of display processing performed by the schedule creation unit is shown. In this third embodiment, instead of the intention of the designer who created the CAD data or the preset update time, it is determined whether to display or update the thumbnails in the "work bar" based on the progress information of design data creation, and other The configuration is almost the same as that of Embodiment 1 and Embodiment 2 described above. Therefore, the same reference numerals are assigned to the same components as those in Embodiment 1 and Embodiment 2, and detailed description thereof will be omitted.

[0055] like Image 6 As shown, the equipment manufacturing / management ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com