Package structure and package method for high definition LED display screen module

A technology for LED display and module packaging, applied in the direction of identification devices, instruments, electrical components, etc., can solve the problem of not meeting the requirements of high-definition LED display, and achieve the effect of reasonable packaging structure layout, reasonable layout and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

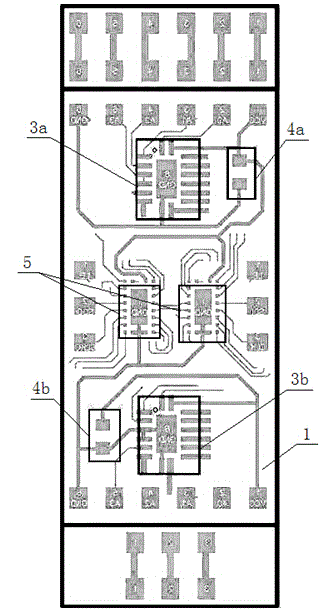

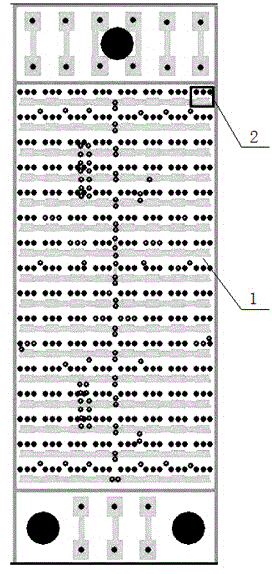

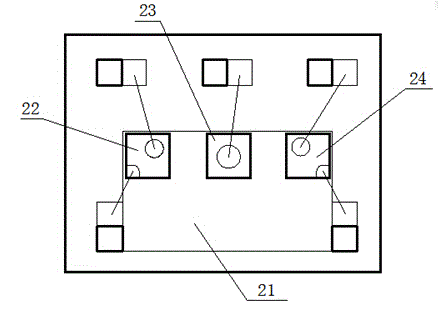

[0029] See figure 1 and figure 2 , high-definition LED display module packaging structure, including a PCB board 1, 128 pixel units 2 connected to the front of the PCB board 1 and arranged in a determinant (8x16), two QFN circuits 3a connected to the back of the PCB board 1, 3b, two capacitors 4a, 4b and two driver IC chips 5, the LED potting adhesive layer coated on the surface of 128 pixel units 2 and the vinyl layer coated on the surface of the driver IC chip 5; the adjacent two The distance between the centers of the pixel units 2 is 1.5mm; two driver IC chips 5 are connected to the middle of the back of the PCB board 1, two QFN circuits 3a, 3b and two capacitors 4a, 4b are divided into two groups, respectively located in the two driver ICs Above and below the chip 5, that is, one of the QFN circuits 3a and one capacitor 4a are located above the two driver IC chips 5, and the other QFN circuit 3b and another capacitor 4b are located below the two driver IC chips 5;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com