Dual selective laser sintering and nonmetal and metal melting 3D (three-dimensional) printing system

A technology of selective sintering and 3D printing, applied in the field of additive manufacturing, to achieve the effect of small spot diameter, avoid warping, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

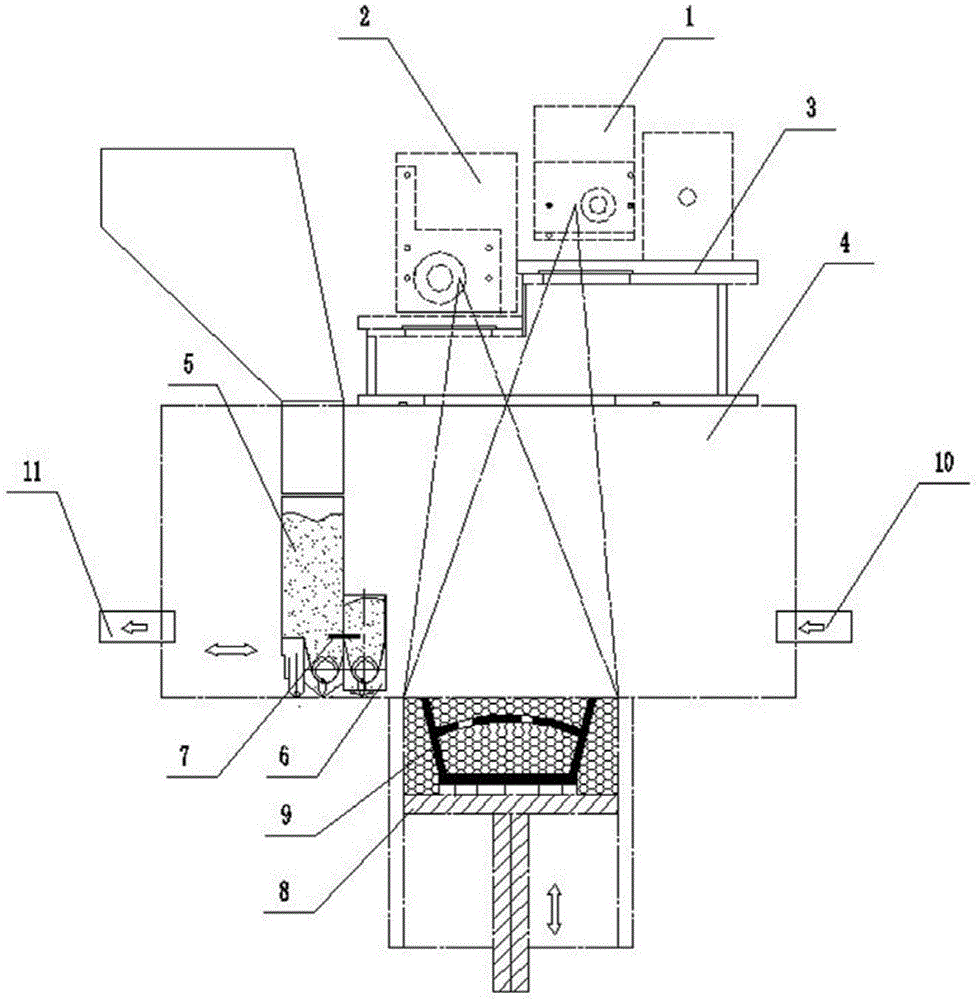

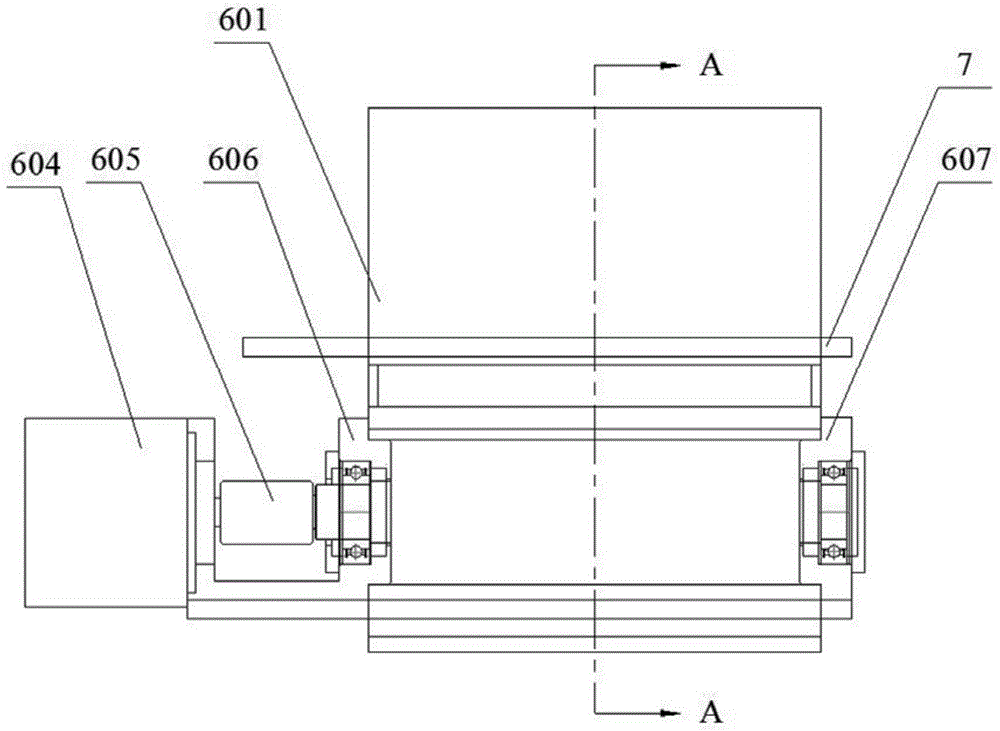

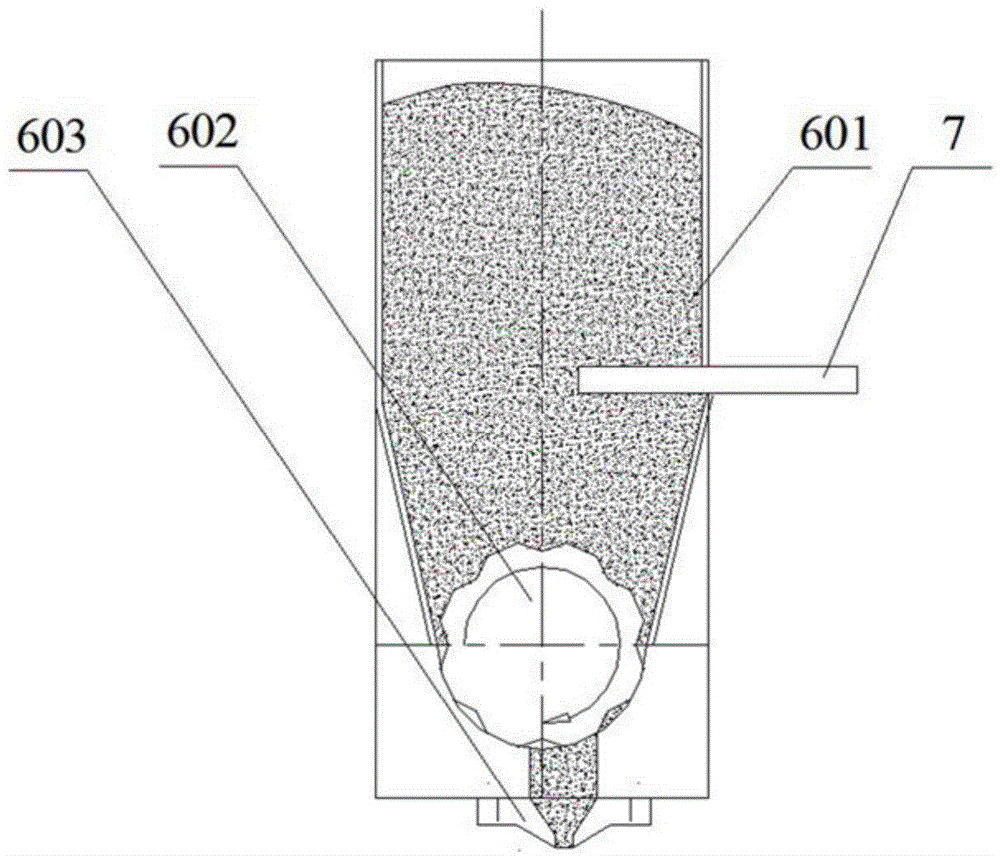

[0028] refer to figure 1 , the 3D printing system for double laser selective sintering and melting of non-metal and metal of the present invention includes: two sets of laser scanning devices (carbon dioxide laser scanning device 1, fiber laser scanning device 2), frame 3, working chamber 4, main shop Powder device 5, atmosphere protection device (not shown) and control device (not shown), wherein, two sets of laser scanning devices (carbon dioxide laser scanning device 1, fiber laser scanning device 2) are installed on the frame 3, the frame 3 is set above the working chamber 4, the main powder spreading device 5 is set in the working chamber 4, the bottom of the working chamber 4 is provided with a working cylinder 8, the piston of the working cylinder 8 moves up and down in the vertical direction, and the workpiece 9 is placed in the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com