Efficient treatment method for printing and dyeing wastewater

A technology for printing and dyeing wastewater and treatment methods, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high cost, poor treatment effect, and high inorganic salt content, and achieves Simple process, zero-emission, high-efficiency treatment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

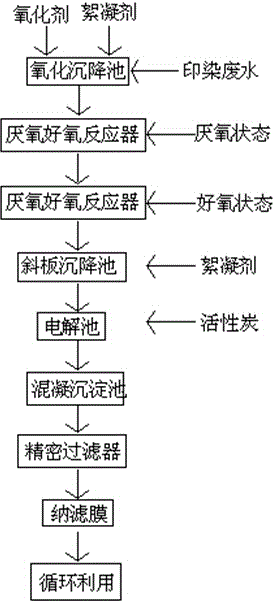

Image

Examples

Embodiment 1

[0025] This example discloses a high-efficiency treatment method for printing and dyeing wastewater. The printing and dyeing wastewater is transported to an oxidation sedimentation tank, and ferrous sulfate or potassium permanganate oxidant is added first, and after stirring evenly, it is left to stand for oxidative treatment for 30 to 90 minutes, so that harmful The substance is oxidized and decomposed; then add coagulant polyaluminum chloride accounting for 1% of the waste water to it, stir evenly, let it settle for 6-24 hours, filter, pass the supernatant through a mechanical grid, and introduce anaerobic In the aerobic reactor, the anaerobic aerobic reactor is adjusted to an anaerobic state by passing inert gas to discharge the air at this time, and the printing and dyeing wastewater is allowed to stand for anaerobic treatment for 5 to 15 minutes, so that the azo dyes are degraded into aromatic amines At the same time, the settled sludge at the bottom of the oxidation sedim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com