Nanometer polymer blocking agent for water-based drilling fluid and preparation method thereof

A nano-polymer and water-based drilling fluid technology, applied in the direction of drilling compositions, chemical instruments and methods, can solve problems such as lack of in-depth research, failure to achieve plugging effects, and damage to drilling tools, and achieve The preparation method is simple and easy, the effect of preventing well wall collapse and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] ①In a 100ml three-necked flask, dissolve 0.8164g (10mmol) of piperazine in 20ml of water, add 1.0317g (10mmol) of diethylenetriamine under stirring, and fill with N 2 Slowly add 2.363g (20mmol) divinyl sulfone dropwise under the condition of 2 15min, sealed with a reversible rubber stopper. React at 45°C for 12 hours.

[0031] ② After the reaction, precipitate with 500ml of methanol for 4-6 hours, filter with suction, wash once with methanol, and then vacuum-dry at 65°C for 12-24 hours to obtain a white powdery solid.

Embodiment 2

[0033] ①In a 100ml three-necked flask, dissolve 0.8164g (10mmol) of piperazine in 20ml of N,N-dimethylformamide, add 1.0317g (10mmol) of diethylenetriamine under stirring, and fill with N 2 Slowly add 2.363g (20mmol) divinyl sulfone dropwise under the condition of 2 15min, sealed with a reversible rubber stopper. React at 45°C for 12 hours.

[0034] ② After the reaction, precipitate with 500ml methanol for 4-6 hours, filter with suction, wash once with methanol, and then vacuum-dry at 65°C for 12-24 hours to obtain a white powdery solid.

[0035] 2. Structural characterization and performance test of a nanopolymer plugging agent for water-based drilling fluid

[0036] (Taking the nanopolymer blocking agent prepared in Example 1 as an example)

[0037] 1. Structural characterization of nanopolymer plugging agent

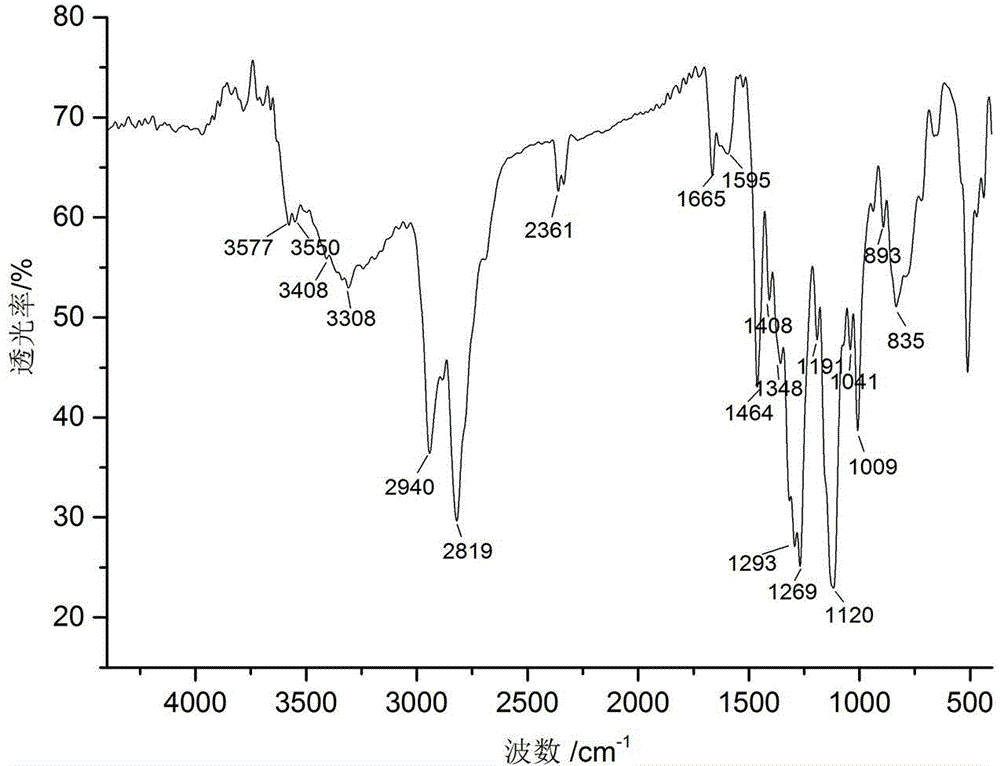

[0038] Characterize the structure of this nanometer polymer plugging agent with infrared spectrometer, its infrared spectrogram sees figure 1 . from figure 1 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com