A kind of organosilicon wear-resistant and hardened coating and preparation method thereof

A technology of hard coating and silicone, applied in the field of silicone wear-resistant hard coating and its preparation, can solve the problems of high preparation cost of acrylic resin system, reducing the transparent effect of plastic surface coating, incapability of popularization and application, and the like, To achieve the effect of strong appearance, good protection and low application cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

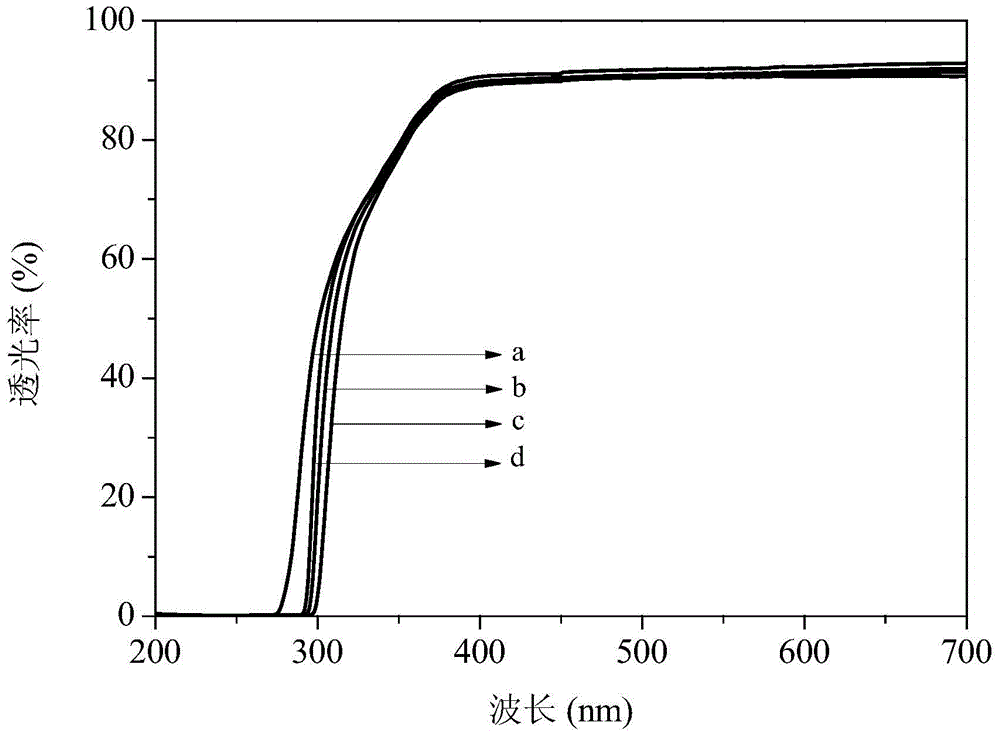

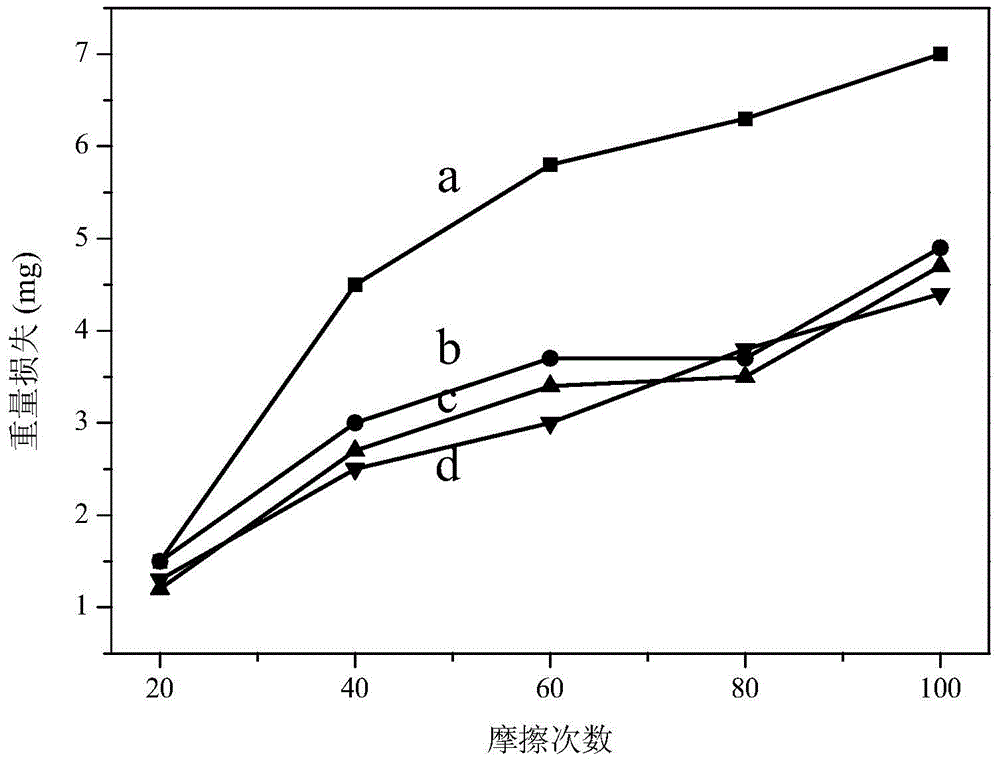

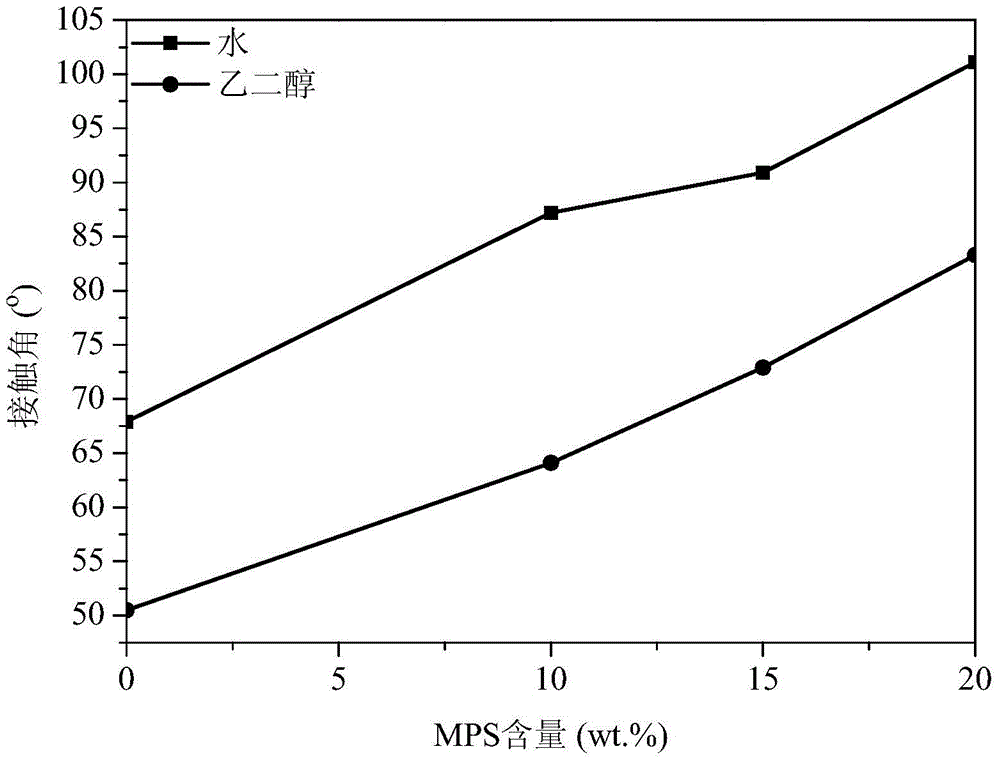

Embodiment 1

[0022] A silicone wear-resistant hard coating. The first is the preparation of the coating: 90 parts by weight of bisphenol A type epoxy acrylic resin (E03 type epoxy resin and acrylic acid are mixed uniformly in a molar ratio of 1:2, and triphenylphosphine is added as a catalyst. The weight of the catalyst is bisphenol A type 0.2% of the total weight of epoxy resin and acrylic acid, react 4h under the condition of 80 ℃ to obtain bisphenol A type epoxy acrylic resin); KH-570 silane coupling agent (γ-methacryloxypropyl trimethoxy silane) 10 parts by weight. The second is the surface pretreatment of the substrate: cut the plexiglass (PMMA) plate into: 6×6cm 2 specifications, followed by NaOH / Na 2 CO 3 Alkaline cleaning-ultrasonic vibration cleaning-distilled water and absolute ethanol alternate cleaning-isopropanol drying, drying for later use. Finally, 90 parts by weight of bisphenol A type epoxy acrylic resin and 10 parts by weight of KH-570 silane coupling agent are mixed...

Embodiment 2

[0025] A silicone wear-resistant hard coating. The first is the preparation of the coating: 85 parts by weight of bisphenol A type epoxy acrylic resin (E03 type epoxy resin and acrylic acid are mixed uniformly in a molar ratio of 1:2, and triphenylphosphine is added as a catalyst. The weight of the catalyst is bisphenol A type 0.2% of the total weight of epoxy resin and acrylic acid, react 4h under the condition of 80 ℃ to obtain bisphenol A type epoxy acrylic resin); KH-570 silane coupling agent (γ-methacryloxypropyl trimethoxy silane) 15 parts by weight. The second is the surface pretreatment of the substrate: cut the plexiglass (PMMA) plate into: 6×6cm 2 specifications, followed by NaOH / Na 2 CO 3 Alkaline cleaning-ultrasonic vibration cleaning-distilled water and absolute ethanol alternate cleaning-isopropanol drying, drying for later use. Finally, 85 parts by weight of bisphenol A type epoxy acrylic resin and 15 parts by weight of KH-570 silane coupling agent are mixed...

Embodiment 3

[0028] A silicone wear-resistant hard coating. The first is the preparation of the coating: 80 parts by weight of bisphenol A type epoxy acrylic resin (E03 type epoxy resin and acrylic acid are mixed uniformly in a molar ratio of 1:2, and triphenylphosphine is added as a catalyst. The weight of the catalyst is bisphenol A type 0.2% of the total weight of epoxy resin and acrylic acid, react 4h under the condition of 80 ℃ to obtain bisphenol A type epoxy acrylic resin); KH-570 silane coupling agent (γ-methacryloxypropyl trimethoxy silane) 20 parts by weight. The second is the surface pretreatment of the substrate: cut the plexiglass (PMMA) plate into: 6×6cm 2 specifications, followed by NaOH / Na 2 CO 3 Alkaline cleaning-ultrasonic vibration cleaning-distilled water and absolute ethanol alternate cleaning-isopropanol drying, drying for later use. Finally, 80 parts by weight of bisphenol A type epoxy acrylic resin and 20 parts by weight of KH-570 silane coupling agent are mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com