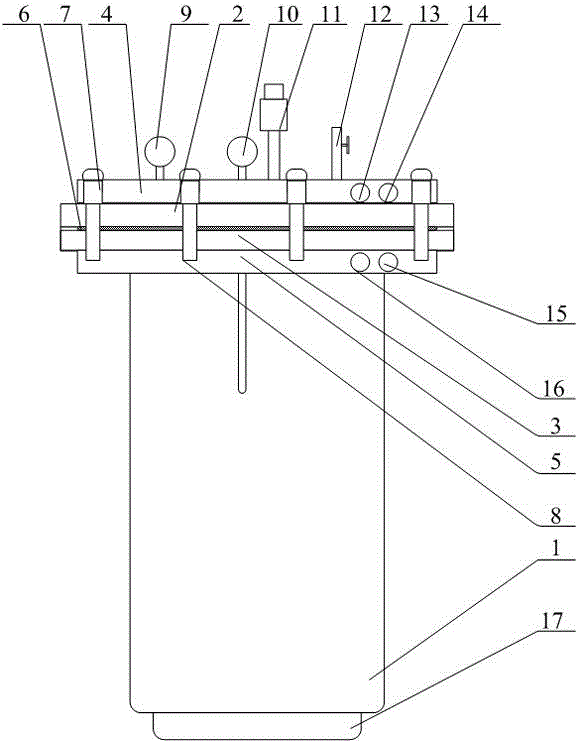

Copper wire annealing pot and annealing method

A technology for annealing pots and copper wires, which is applied to furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of annealing temperature that cannot meet process requirements, heating temperature cannot be kept consistent, affecting annealing effect, etc., so as to ensure the annealing effect. , to ensure the sealing performance, improve the effect of gloss and color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1), hoist the bare copper wire with a width of 1-2CM into the annealing tank. When loading the furnace, care should be taken to hoist it gently, and place the interlayer cushion to prevent the bare copper wire from being damaged;

[0026] 2) Check whether the sealing ring is in good condition, cover the tank cover and tighten the hand nut, and ensure that each hand nut is uniformly stressed, and then lift and transfer it to the electric tank. The lifting process should be stable and safe;

[0027] 2), connect the vacuum pipe to the vacuum pump to vacuumize the tank, and the pressure is -0.07Mpa to -0.13Mpa;

[0028] 3), fill the protective gas carbon dioxide into the tank through the inflation tube, the pressure reaches 0.07Mpa to 0.13Mpa, and the sufficient time is 15min-20min;

[0029] 4) Heat and keep the annealing tank through the electric tank, the heating temperature is 280℃-370℃, the heating time is 150min-200min, and the holding time is 60min-100min; during the ...

Embodiment 2

[0032] The width of the bare copper wire is 2-3CM, the heating temperature is 330°C-470°C, the heating time is 200min-240min, the holding time is 180min-240min, the cooling time is 20-24h, and the remaining steps are the same as in Example 1.

Embodiment 3

[0034] The width of the bare copper wire is 3-4CM, the heating temperature is 430°C-520°C, the heating time is 240min-280min, the holding time is 240min, and the cooling time is 24-28h, and the remaining steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com