Axial-flow type thermoelectric device

A thermoelectric device and axial flow technology, which is applied to gas turbine devices, motor starting for engines, combined combustion mitigation, etc., can solve the problems of restricted performance, limited thermoelectric conversion efficiency, and inability to configure generators for aviation micro-turbojet engines. Achieve the effect of improving energy efficiency, improving battlefield survivability, and maintaining power supply capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] It can be used in a relatively small or closed space as a heat source and power source, such as a heating power generation device in a tank or an armored vehicle.

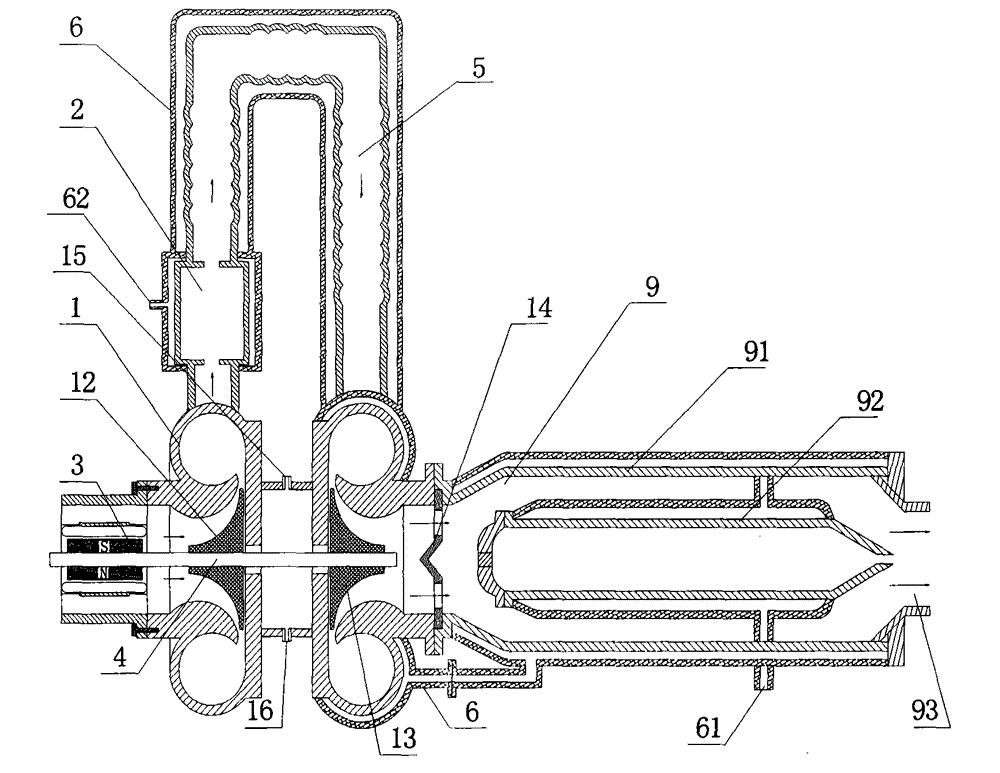

[0030] as attached figure 1 Shown, transform on the basis of the turbocharger of existing automobile engine, thus constitute the air compressor and the micro-turbine turbine of this embodiment; Combustion chamber 2 is provided between compressor 1 and micro-gas turbine 13 , the compressor outlet is communicated with the combustion chamber, and the combustion chamber hot air outlet is communicated with the micro-turbine turbine inlet through the flame conduit 5, which becomes the turbine burner of the present embodiment;

[0031] The heat exchanger 9 is a double-layer heat exchanger, and the inner heat exchange layer 92 is placed in the inner cavity of the outer heat exchange layer 91; the air inlet of the heat exchanger 9 communicates with the air outlet of the turbine burner;

[0032] The starter generator...

Embodiment 2

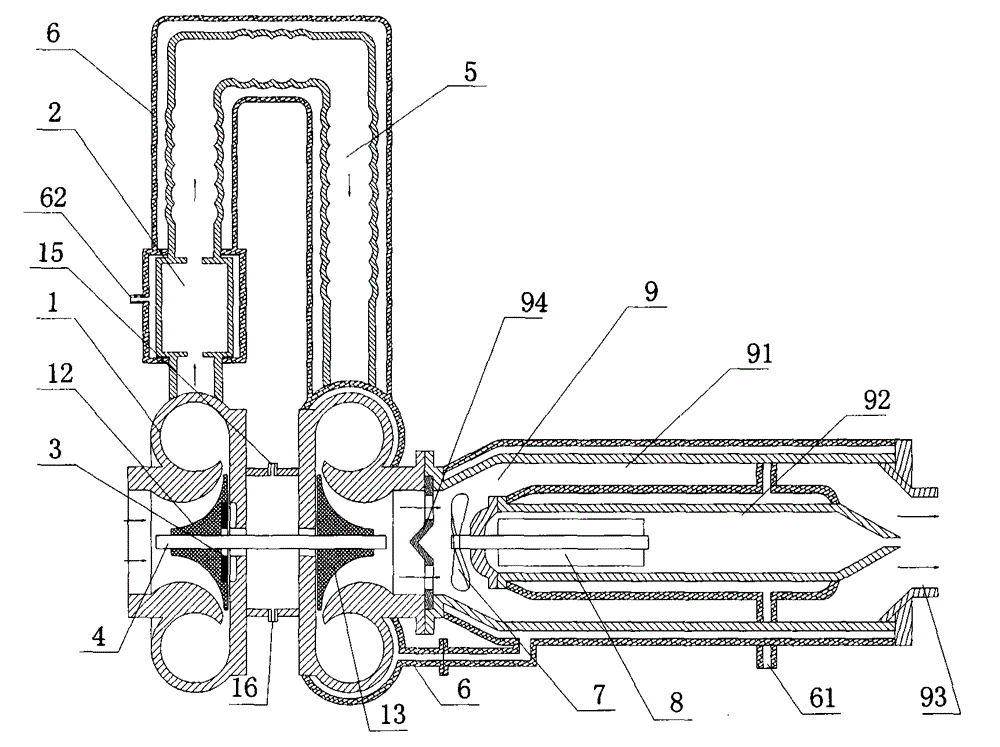

[0038] as attached figure 2 As shown, the basic structure is the same as in Embodiment 1.

[0039] An axial power turbine 7 and a generator 8 are installed in the heat exchanger, the axial power turbine 7 is arranged at the end of the inner heat exchange layer 92 at the air inlet of the heat exchanger, and the generator 8 is placed in the inner heat exchange layer The hollow cavity of 92 is driven by the axial power turbine 7 through its rotating shaft.

[0040] A deflector 14 is provided at the air inlet of the heat exchanger.

[0041] The generator 8 adopts a column-type motor, the column-type stator coil is fixed to the inner heat exchange layer, and the stator coil surrounds the column-type permanent magnet rotor; the permanent magnet rotor and the rotating shaft are fixed with fastening nuts, and are driven on the rotating shaft of the power turbine.

[0042]The starter generator 3 adopts a disc structure motor; the permanent magnet rotor of the starter generator is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com