Buoyancy type flow distributor and sealing oil vacuum efficient degasser

A technology of flow distributor and degassing device, applied in valve device, liquid degassing, engine sealing, etc., can solve the problems of rising hydrogen production cost, purchasing hydrogen cost, outage of generator set, limited hydrogen production capacity, etc. The effect of improving safety and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

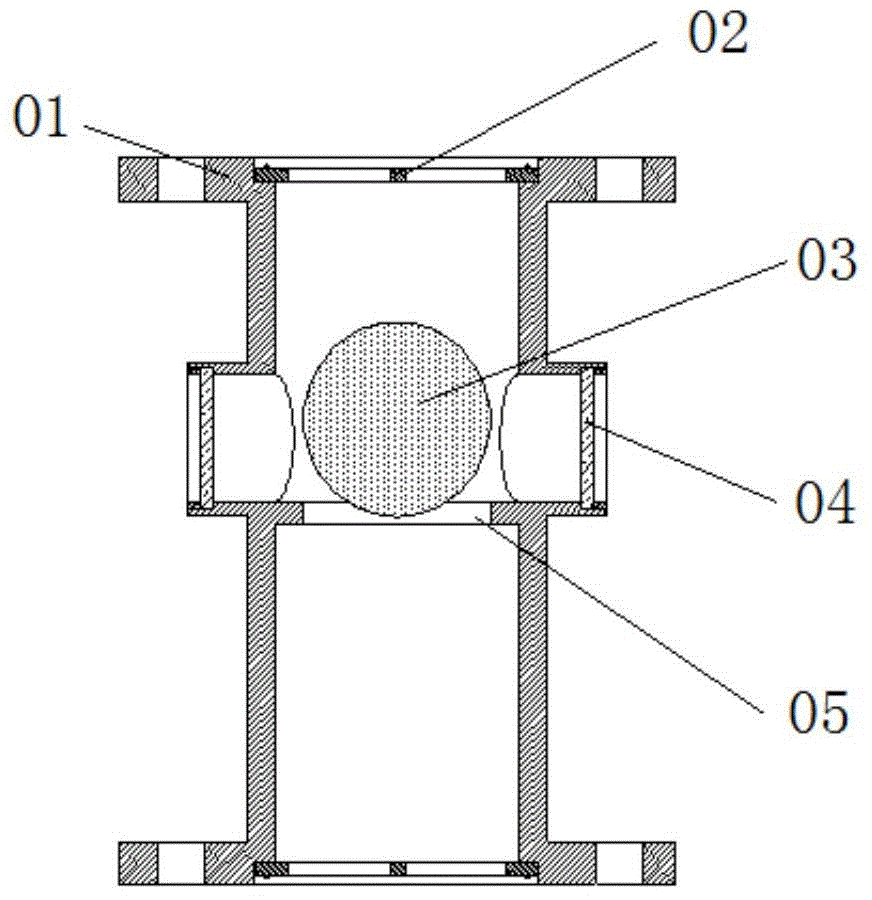

[0027] Such as figure 1 As shown, a buoyancy flow distributor of the present invention includes a distributor body 01, a floating ball 03 placed in the distributor body 01 that is substantially close to the density of the sealing oil, and is arranged at the upper and lower ends of the distributor body 01 to limit the floating The baffle plate 02 for ball displacement, the throat neck 05 which is set in the middle position of the distributor body 01 and plays the role of the middle switch position, the sight glass 04 which is arranged on the side wall of the distributor body 01 for observing the position of the floating ball, said The inner diameter of the throat 05 is the same as that of the float 03.

[0028] As a preferred embodiment of the present invention, both sides of the upper end and the lower end of the distributor body 01 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com