CO2 supercritical extraction temperature fraction order PID control method

A technology of extraction temperature and control method, which is applied in the direction of temperature control using electric mode, which can solve the problems of non-linearity and difficulty in ensuring precise control of extraction temperature, and achieve the effect of improving performance and overcoming many setting parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The method of the present invention includes the following steps:

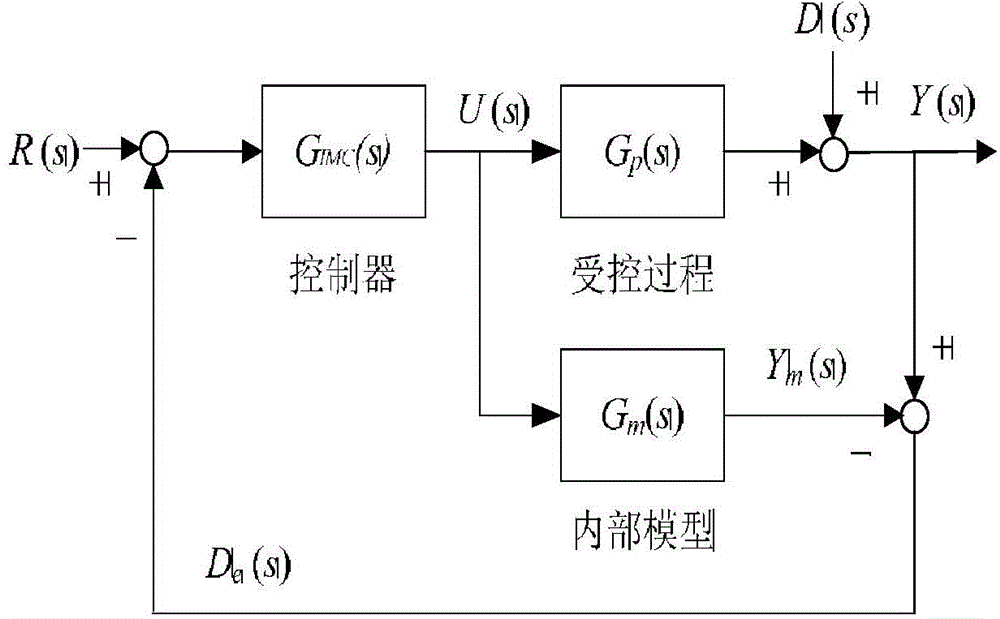

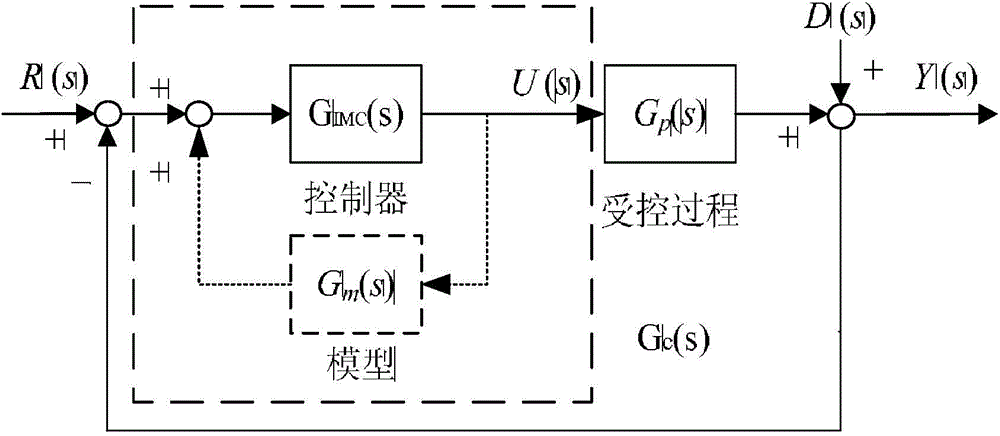

[0050] 1. The temperature control system used mainly includes: analog quantity acquisition circuit, fractional PID controller, PWM drive circuit. The present invention expresses the transfer function in a fractional-order system, and the response ability, anti-interference ability and adjustment ability of the fractional-order PID control method are better than those of the integer-order PID control method. The combination of internal model control and fractional-order control can overcome the controller The disadvantages of more tuning parameters can improve the performance of the control system. At the same time, based on OPC technology, WinCC is used as a bridge to enable MATLAB / Simulink and S7-200PLC to realize real-time communication, and the fractional PID control algorithm on Simulink can control the temperature of the extraction kettle. Perform real-time control.

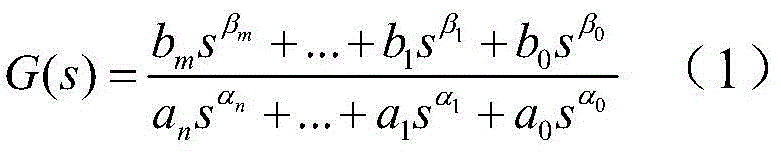

[0051] 2. Establish a temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com