Main transformer nitrogen protection breather and application method thereof

A breathing device, nitrogen protection technology, applied in the direction of transformer/inductor cooling, etc., can solve the problems of easily polluted oil products, pollution, main transformer explosion, etc., and achieve the effect of long-term stable oil quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

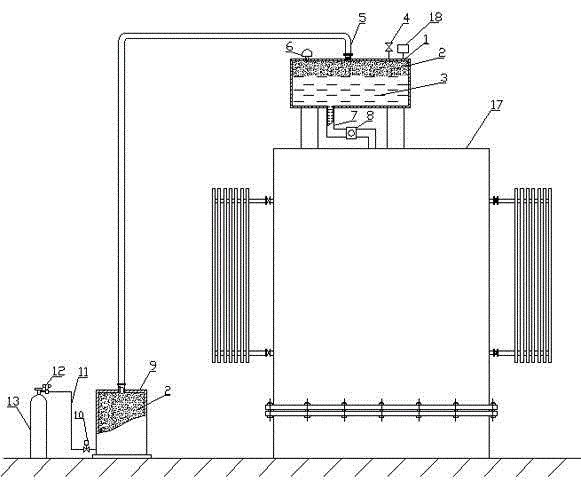

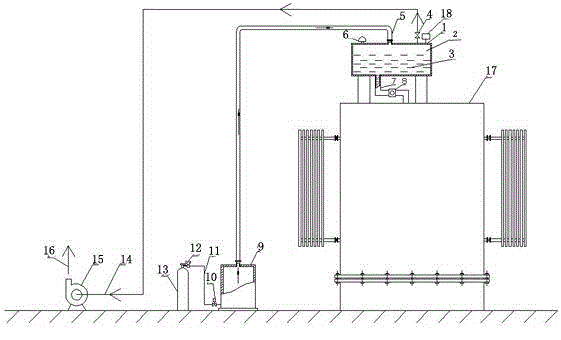

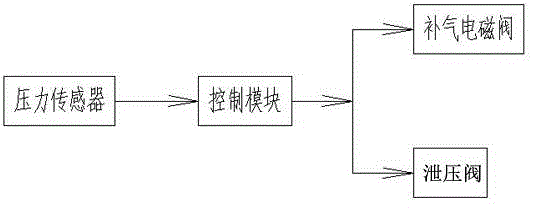

[0025] like figure 1 as well as image 3 As shown, this embodiment provides a main transformer nitrogen protective breathing device, including a main transformer body 17, and the main transformer body 17 is connected to the bottom of an oil conservator 1 through an oil conservator connecting pipe 7, and the oil conservator 1 is a cylindrical storage cabinet made of metal with both ends sealed. A gas relay 8 is installed on the oil conservator connecting pipe 7. The top of the oil conservator 1 is connected to one end of a breathing nitrogen tank 9 through a breathing tube 5. The other end of the breathing nitrogen tank 9 is provided with an air supply solenoid valve 10, and the air supply electromagnetic valve 10 is connected to an air outlet of a high-purity nitrogen supply device 13 through a supply air connecting pipe 11, and the high-purity nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com