Substrate integrated waveguide ferrite tunable band-pass filter

A substrate-integrated waveguide and ferrite technology, applied in waveguide-type devices, electrical components, circuits, etc., can solve the problems of low feasibility, signal interference, poor electromagnetic compatibility, etc., and achieve easy planarization and integration, The effect of large power capacity and easier integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

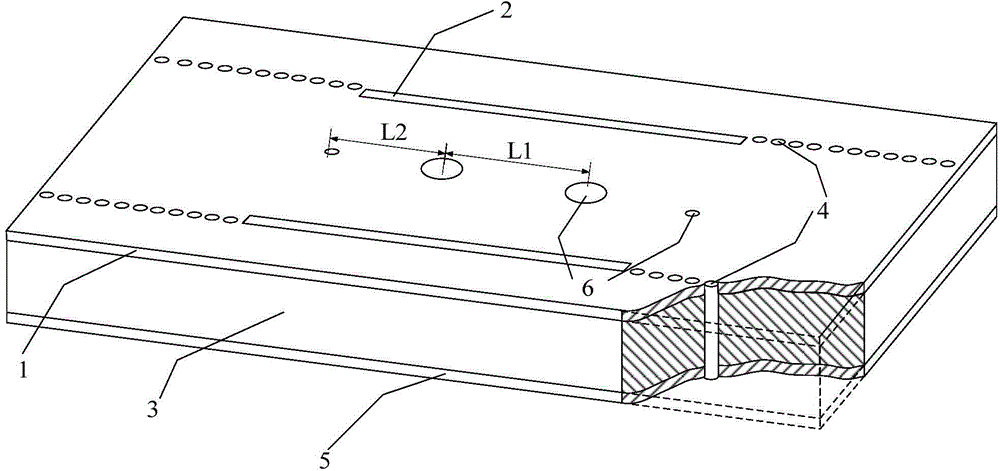

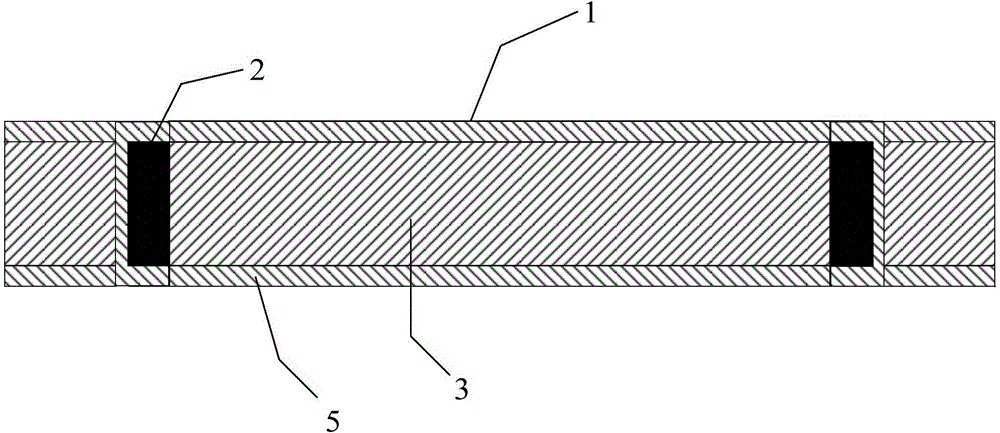

[0031] Such as figure 1 , figure 2 As shown, the substrate-integrated waveguide ferrite tunable bandpass filter in this embodiment includes metallized copper-clad upper layer 1 and ferrite metallized on three sides (near the outer side and upper and lower surfaces of the narrow edge of the substrate-integrated waveguide). Body block 2, dielectric substrate 3, narrow-side metallized through hole 4, metal copper-clad lower layer 5, central inductive metallized through-hole 6; the substrate integrated waveguide consists of metal copper-clad upper layer 1 and metal copper-clad lower layer 5 through two rows of mutual The parallel narrow-side metallized through holes 4 are connected together and constituted together with the corresponding dielectric substrate 3; the center of the substrate integrated waveguide dielectric layer 3 is the central inductive metallized through hole 6, and the two sides of the dielectric substrate 3 are embedded with three-sided metallized ferrite bloc...

Embodiment 2

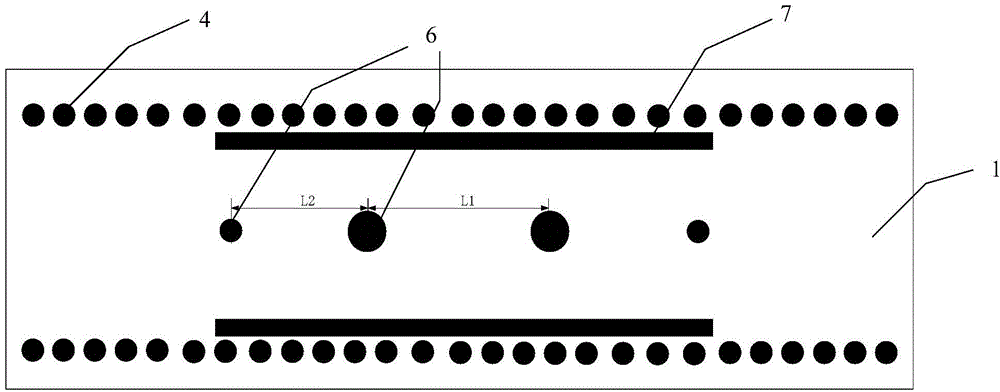

[0034] Such as image 3 , Figure 4 As shown, in this embodiment, the substrate-integrated waveguide ferrite tunable bandpass filter includes a metal-clad copper upper layer 1, a ferrite block 7 metallized on the upper and lower surfaces, a dielectric substrate 3, and narrow-side metallized Through hole 4, metal copper-clad lower layer 5, central inductive metallized through hole 6; the substrate integrated waveguide is connected by metal copper-clad upper layer 1 and metal copper-clad lower layer 5 through two rows of metallized through-holes 4 parallel to each other, and corresponding The dielectric substrate 3 is formed together; the center of the substrate integrated waveguide dielectric layer 3 is a central inductive metallization through hole 6, and the two sides of the substrate integrated waveguide are embedded with metallized ferrite blocks 7 on the upper and lower surfaces, and the outside of the ferrite block 7 If the processing technology allows, it should be as c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com