Highly absorbing layer system, method for producing the layer system and suitable sputtering target therefor

A technology of sputtering target and absorbing layer, which is applied in the field of sputtering target and can solve the problems of toxic Cr-Vl compounds and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

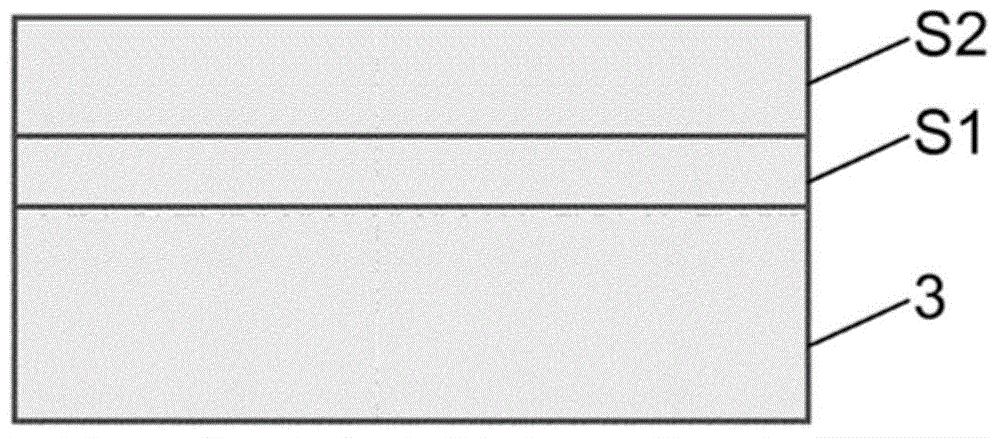

[0080] Table 1 shows the corresponding metal contents of the sputtering targets used and for Nb with Mo 2 o 5 Layer thicknesses of layers S1 and S2 of the layer system, and deposition conditions. Transmission T V The results of the measurements on the layer stack are given in Table 2 and the reflection Rv (deduction of 4% of the reflection on the front side of the uncoated glass substrate) and the Kappa absorption index at 550 nm.

[0081] Table 1 (deposition conditions)

[0082]

[0083] Table 2 (layer characteristics)

[0084]

[0085]

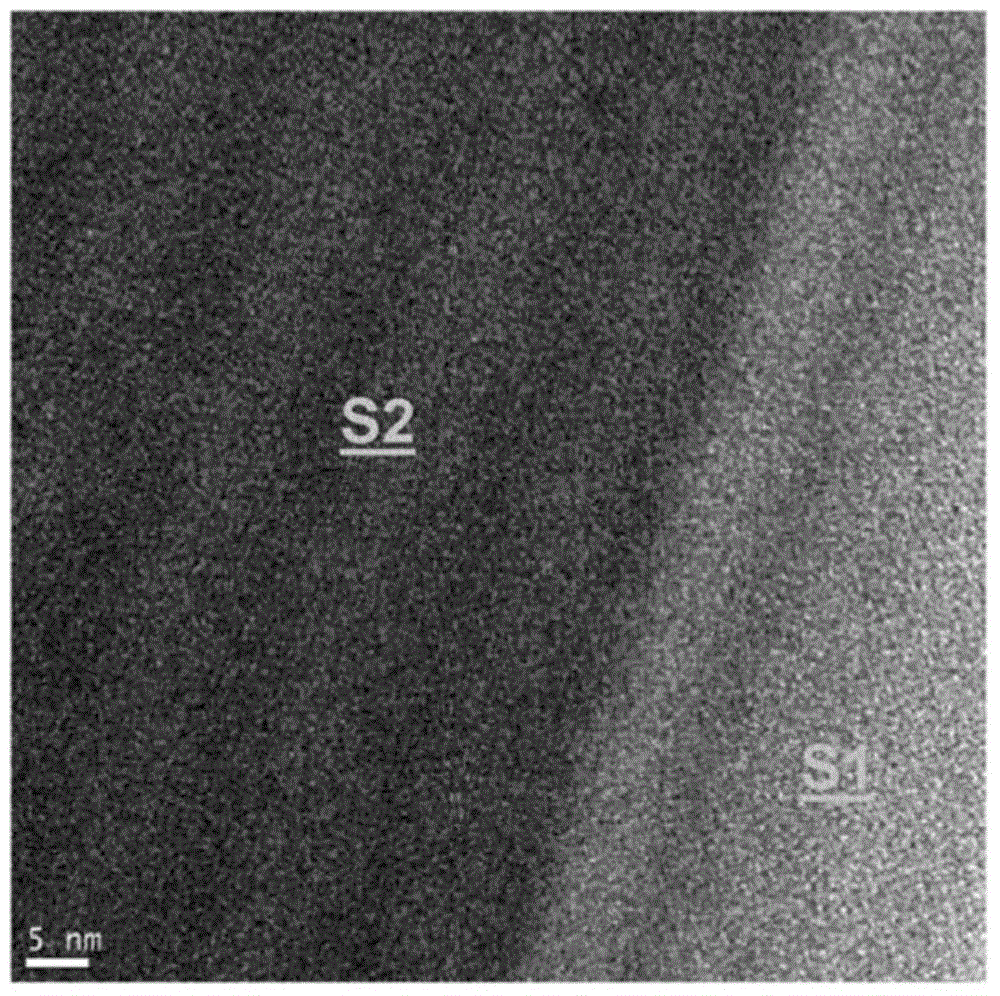

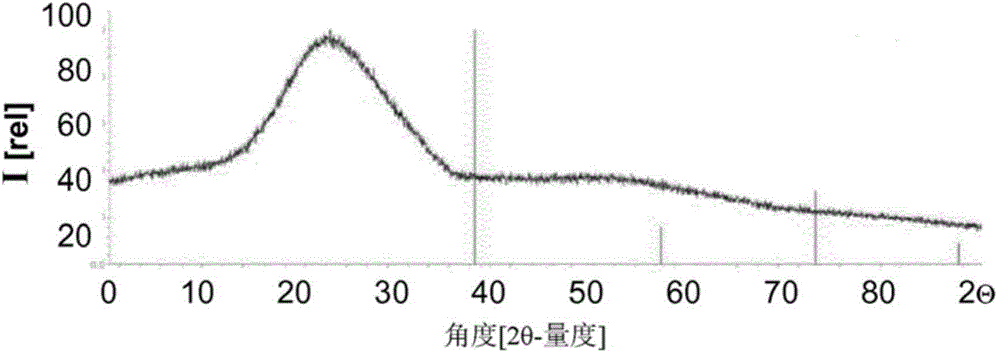

[0086] Note on the indicated weight ratios (wt%) of Mo: This indication refers to the content of Mo metal in the target material, respectively. In these layers and especially in the absorber layer S2, with a distribution of oxygen in Nb and Mo that cannot be determined in an exact manner, substoichiometric oxides Nb-Mo-O are formed x composed of an amorphous structure.

[0087] Requirements regarding visible transmission (Tv<1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com