A modular installation device for large equipment

A technology for large-scale equipment and installation devices, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc. It can solve the problems of inability to meet modular assembly, increase the overall height of equipment, and the fixed base cannot be disassembled, so as to save transportation costs. Small footprint and reduced control accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The structural composition of each part of device of the present invention is described as follows:

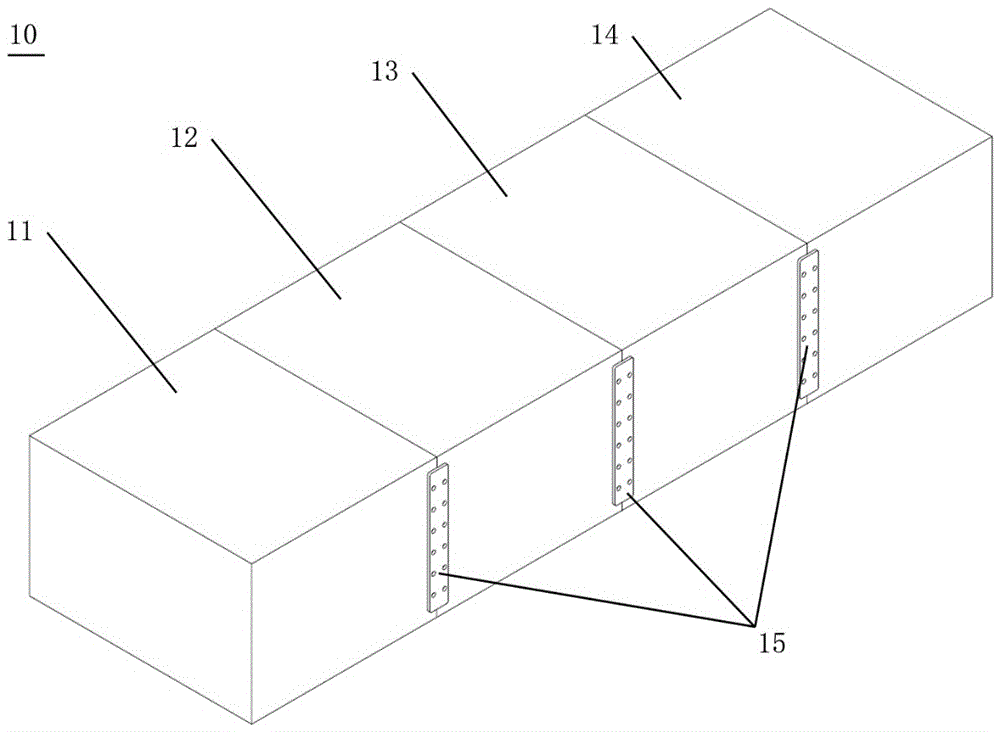

[0037] like figure 1 As shown, the modular large-scale machinery production line 10 includes: a first module 11 , a second module 12 , a third module 13 , a fourth module 14 and a module connecting structure 15 . For the sake of simplicity, each module in the figure is simplified into a cuboid, and adjacent modules are connected by a module connecting structure 15 .

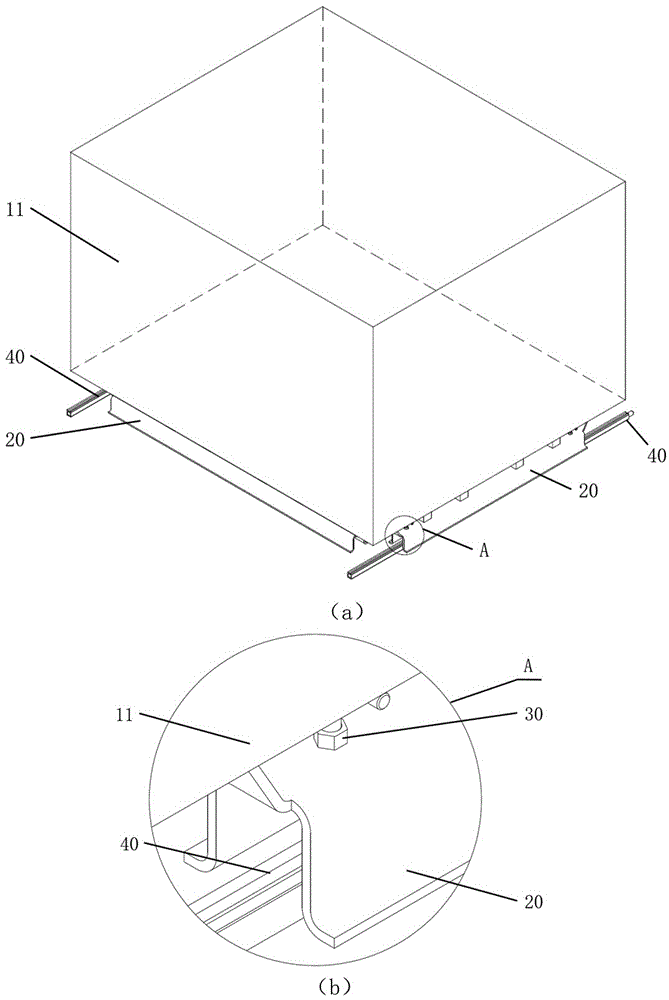

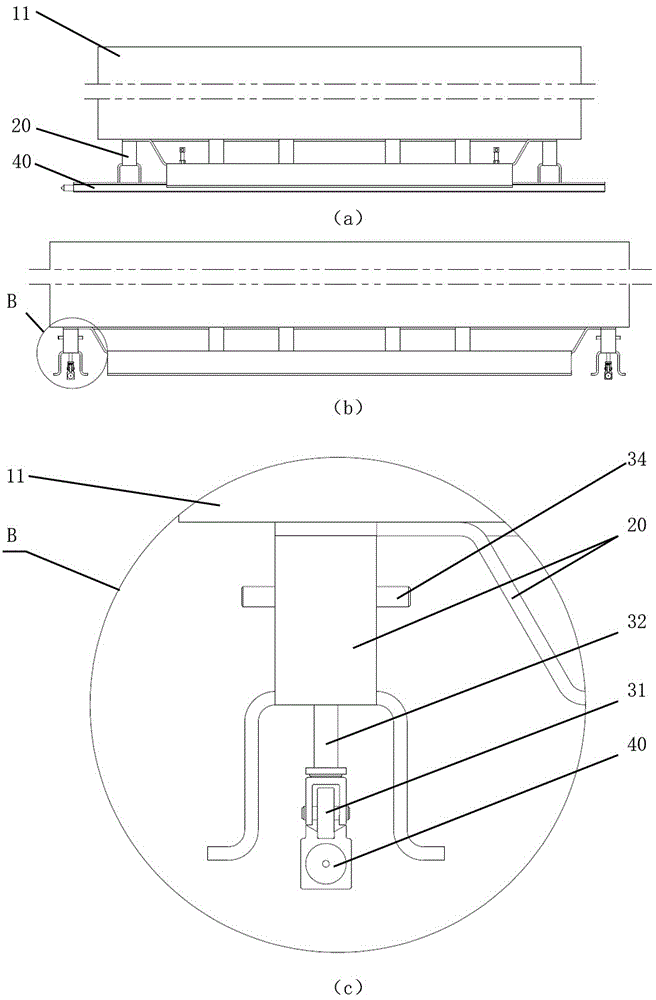

[0038] like figure 2 , image 3 As shown, the track 40 is laid on the ground at the use site, the screw lifter 30 is welded on the chassis 20, the screw lifter 30 contacts the groove of the track 40 through the universal wheel 31, and the module to be installed in the mechanical production line ( figure 2 , image 3 The first module 11 is taken as an example) placed above the chassis 20 and connected with the chassis 20 by means of welding or bolting.

[0039] like Figure 4 As shown, the chassis 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com