A liquid bromelain preparation with stable enzyme activity

A bromelain and enzyme activity technology, applied in the direction of enzyme stabilization, hydrolytic enzymes, etc., can solve the problems of difficult increase in production capacity, high investment in equipment, time-consuming, etc., and achieve the effect of expanding production capacity, less investment in equipment, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

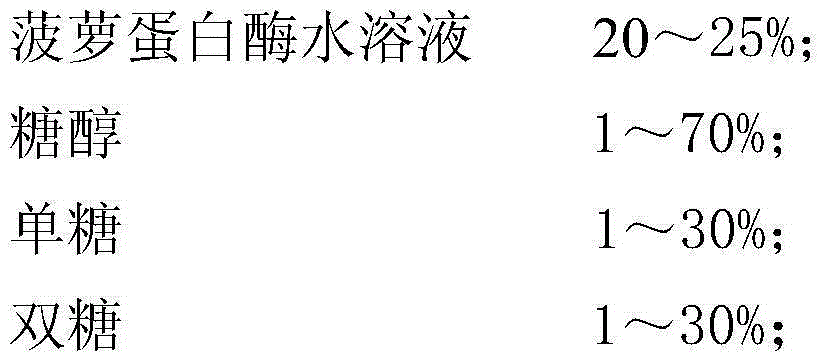

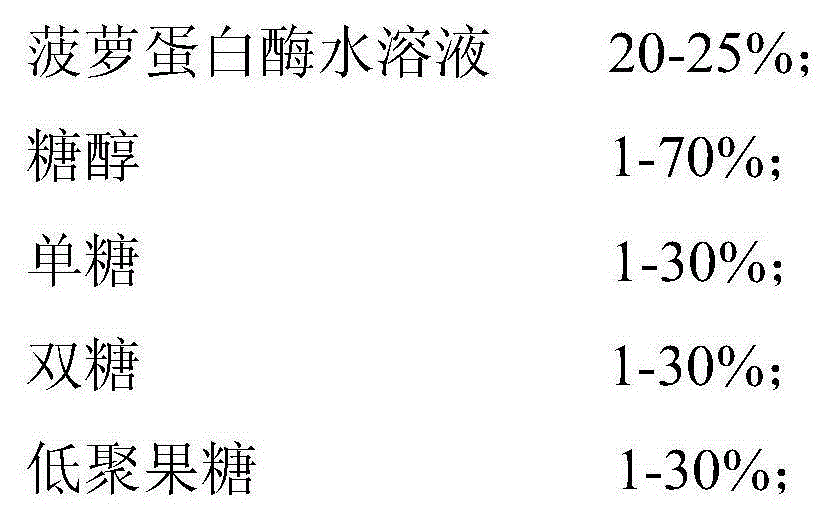

Method used

Image

Examples

Embodiment 1

[0017] Add 600 grams of sorbitol, 50 grams of glucose, 100 grams of sucrose, and 50 grams of sucrose to the 200 grams of pineapple enzyme aqueous solution (the content of bromelain is 4%) that has been preliminarily purified, concentrated and filtered sterilized. The sorbitol, glucose, sucrose and sucrose are food grade or pharmaceutical grade. Stir at room temperature (25°C) (100 r / min) for 60 minutes. After all the added enzyme activity protecting agent is dissolved, adjust the pH to 3 with citric acid solution (2mol / L), and measure the enzyme activity within 2 hours. The enzyme activity was measured after being stored at 0°C for 6 months, and the enzyme activity decreased by 1.8%; the enzyme activity was measured after being stored at 0°C for 6 months, and the enzyme activity decreased by 3.9%.

Embodiment 2

[0019] 520 grams of sorbitol, 150 grams of glucose, 50 grams of sucrose and 50 grams of sucrose fructose were added to 230 grams of pineapple enzyme aqueous solution (5% bromelain content) that had been preliminarily purified, concentrated and filtered. The sorbitol, glucose, sucrose and sucrose are food grade or pharmaceutical grade. Stir at room temperature (25°C) (90 r / min) for 60 minutes. After all the added enzyme activity protecting agent is dissolved, adjust the pH to 3.5 with citric acid solution (2mol / L), and measure the enzyme activity within 2 hours. The enzyme activity was measured after being stored at 35°C for 6 months, and the enzyme activity decreased by 2.3%; the enzyme activity was measured after being stored at 35°C for 6 months, and the enzyme activity decreased by 4.8%.

Embodiment 3

[0021] Add 500 grams of sorbitol, 150 grams of glucose, 50 grams of sucrose, and 50 grams of sucrose to the 250 grams of pineapple enzyme aqueous solution (2% bromelain content) that has been preliminarily purified, concentrated and filtered. The sorbitol, glucose, sucrose and sucrose are food grade or pharmaceutical grade. Stir at room temperature (25°C) (90 r / min) for 60 minutes. After all the added enzyme activity protecting agent is dissolved, adjust the pH to 5 with citric acid solution (2mol / L), and measure the enzyme activity within 2 hours. The enzyme activity was measured after being stored at 4°C for 6 months, and the enzyme activity decreased by 1.3%; the enzyme activity was measured after being stored at 4°C for 6 months, and the enzyme activity was decreased by 3.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com