Rare Earth Ion Activated Complex Phase Fluorescent Materials

A technology of fluorescent materials and rare earth ions, applied in the field of complex-phase fluorescent materials, can solve the problems of single luminous color, inability to match fluorescent powder, weak luminous intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] raw material Weight (g) SrCO 3

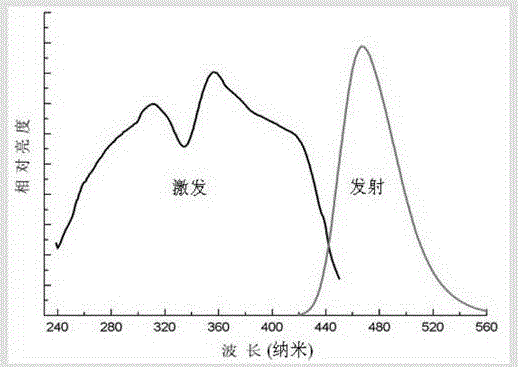

[0039] The raw materials of the above composition are fully ball-milled and mixed, put into a crucible, put into an electric furnace, and sinter in an oxidizing atmosphere at 900°C for 4 hours, and then put it into a flow of 95% hydrogen, 3% nitrogen and 2 % hydrogen sulfide mixed gas furnace for sintering, and sintering at 1100 ° C for 4 hours. After the sintered body is cooled, crush it, grind it with a ball mill, and then sieve it with a 325-mesh sieve to obtain the composite fluorescent material SrO 0.6MgO SiO with blue light emission in the present invention 2 0.02P 2 o 5 : 0.03Eu 2+ 0.25Cl - / 0.23Ag. The excitation spectrum of the material is within the range of 240-450nm, and the position of the main excitation peak is at 358nm; the emission spectrum is within the range of 420-560nm, and the position of the main emission peak is at 467nm.

Embodiment 2

[0041] raw material Weight (g) SrCO 3

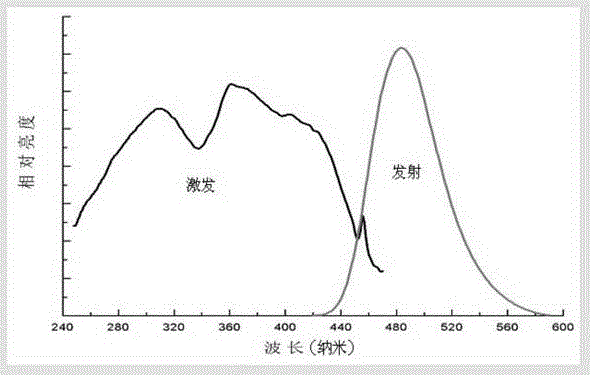

[0042] The raw materials of the above composition are fully ball milled and mixed, put into a crucible, put into an electric furnace, and sinter in an oxidizing atmosphere at 800°C for 6 hours, after cooling, put it into a furnace with hydrogen gas for sintering, and sinter at 1300°C Heat preservation and sintering for 4 hours. After the sintered body is cooled, crush it, grind it with a ball mill, and then sieve it with a 325-mesh sieve to obtain the fluorescent material 0.6SrO 0.2CaO 0.5MgO SiO with blue-green luminescence in the present invention 2 0.02B 2 o 3 0.2P 2 o 5 : 0.01Eu 2 + / 0.17Ag. The excitation spectrum of the material is within the range of 250-470nm, and the position of the main excitation peak is at 362nm; the emission spectrum is within the range of 420-590nm, and the position of the main emission peak is at 485nm.

Embodiment 3

[0044] raw material Weight (g) SrCO 3

[0045] SiO 2

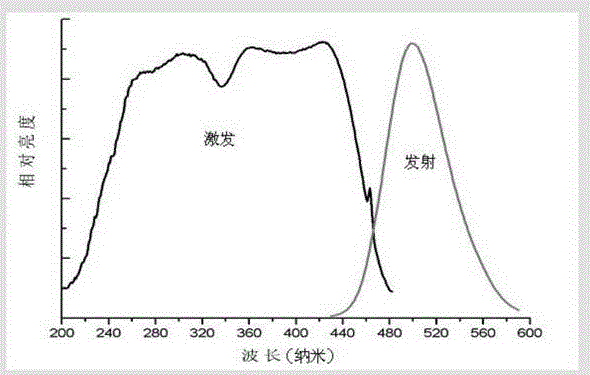

[0046] The raw materials of the above composition are fully ball milled and mixed, put into a crucible, put into an electric furnace, and sinter in an oxidizing atmosphere at 1000°C for 2 hours, after cooling, put it into a furnace with hydrogen gas for sintering, and sinter at 1000°C Heat preservation and sintering for 6 hours. After the sintered body is cooled, crush it, grind it with a ball mill, and then sieve it with a 325-mesh sieve to obtain the multi-phase fluorescent material 0.5SrO 0.5CaO 0.3MgO SiO in the present invention. 2 0.01B 2 o 3 : 0.01Eu 2+ 0.001Mn 2+ / 0.12Ag. The excitation spectrum of the material is within the range of 260-480nm, and the position of the main excitation peak is at 422nm; the emission spectrum is within the range of 430-600nm, and the position of the main emission peak is at 499nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com