Transparent foamed aluminum composite board and preparing method thereof

A technology of composite board and foam aluminum board, applied in chemical instruments and methods, coating, surface pretreatment, etc., can solve the problems of low strength, high production cost, fragile stone, etc., and achieve good transparency, good composite strength and Transparency, strength-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

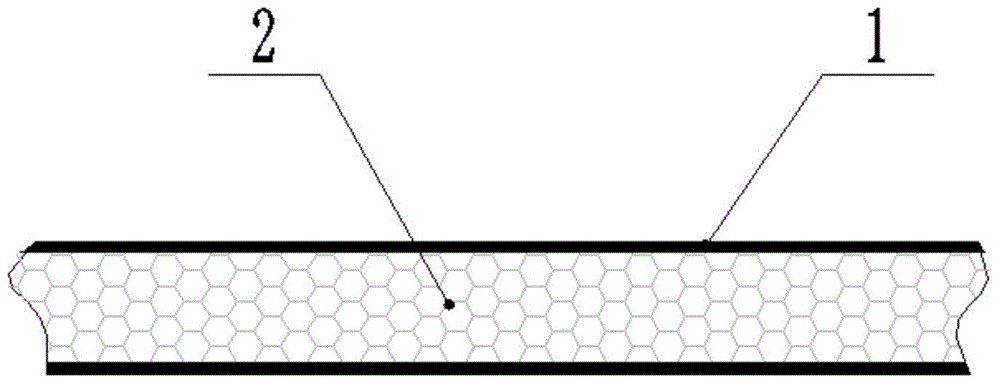

[0016] like figure 1 As shown, the transparent foam aluminum composite board adopts a closed-cell foam aluminum board substrate 1, and a layer of UV resin coating 2 is attached to the surface of the foam aluminum board substrate, and the thickness of the UV resin coating 1 is 1mm higher than the surface of the foam aluminum board substrate 2. . The UV resin coating is epoxy acrylic, acrylic polyurethane, unsaturated polyester, acrylic polyester or acrylic ether resin. UV resin is an oligomer that can rapidly undergo physical and chemical changes in a short period of time after being irradiated by light, and then cross-link and cure. UV resin has various prepolymers due to different types and models, such as epoxy acrylic acid, acrylic polyurethane, unsaturated polyester, acrylic polyester, acrylic ether, etc. After curing, UV resin has the advantages of hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com