Lens wavefront aberration measurement method based on inverse hartmann principle

A technology of wavefront aberration and measurement method, applied in measurement device, measurement optics, optical radiation measurement and other directions, can solve problems such as focus confusion, and achieve the effects of simple device, high measurement accuracy and high spatial resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is attached Figures 1 to 3 Embodiments of the present invention will be described.

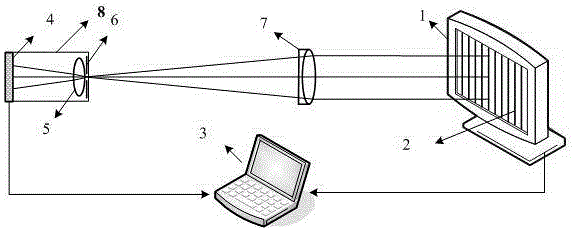

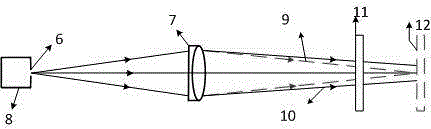

[0021] A lens wavefront aberration measurement method based on the inverse Hartmann principle, the system design is as follows figure 1 As shown, it mainly consists of an LCD display 1, a digital CCD camera 8, and a computer 3. The CCD camera 8 is composed of a CCD detection plane 4, a camera lens system 5 and an external pinhole 6, wherein the pinhole 6 is installed near the outside of the CCD camera lens to eliminate the influence of pupil aberration on the system. Its system measurement principle is as follows figure 2 As shown, if the light propagation direction is viewed according to Hartmann's principle, the pinhole 6 in the system is regarded as a point light source, and the light 10 reaches a certain position on the LCD display screen 11 after passing through the measured lens 7 . There is a deviation between this position and the ideal light 9, and this devia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com