Magnesium-calcium based wet method desulphurization system and method for removing sulfur dioxide in flue gas and producing gypsum

A technology for sulfur dioxide and wet desulfurization, which is applied in the field of magnesium-calcium-based wet desulfurization systems, can solve the problems of easy scaling, increase the size of magnesium-based solid particles, and reduce separation efficiency, so as to improve operation reliability and prevent scaling. Problems, the effect of easy operation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

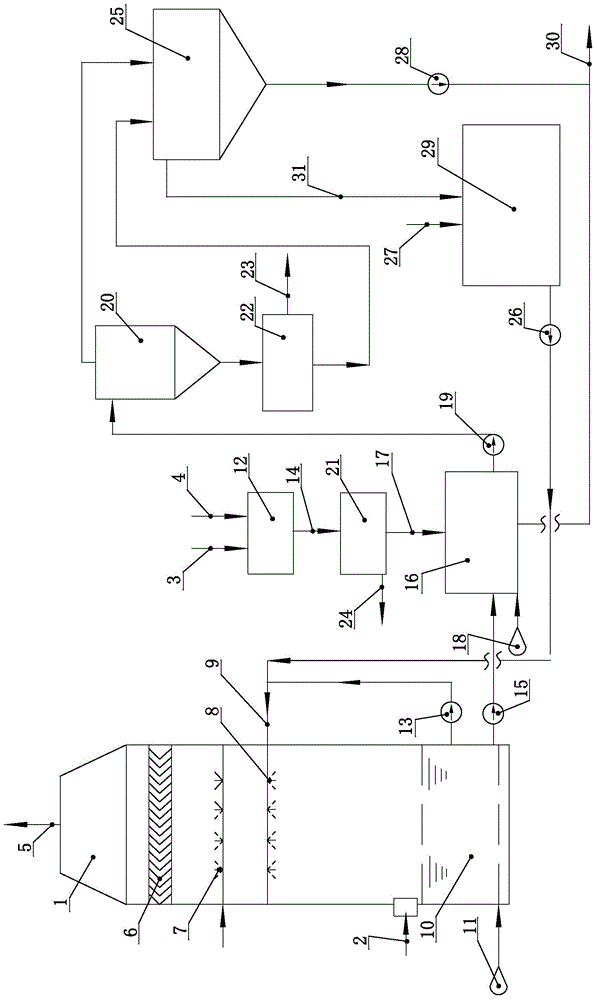

[0046] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0047] Such as figure 1 As shown, a magnesium-calcium-based wet desulfurization system for removing sulfur dioxide in flue gas and producing gypsum is mainly composed of desulfurization reactor 1, magnesium hydroxide supply pipe 9, oxidation tank 10, displacement reactor 16, separator 20, The filter 22, the settling tank 25 and the liquid return tank 29 etc. are composed.

[0048] The desulfurization reactor 1 is usually cylindrical, and the side wall of the desulfurization reactor 1 is provided with a smoke inlet 2 communicating with the inner cavity, and the top of the desulfurization reactor 1 is provided with a smoke outlet 5, and the purified flue gas Exhausted from the top exhaust port 5. On the upper part of the inner chamber of the desulfurization reactor 1, a nozzle tube group 8 is arranged, and the nozzle tube group 8 is connected to the magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com