Clamping device of machine tool

A clamping device and machine tool technology, which is applied in the field of machinery, can solve problems affecting production efficiency, increase operating time, and increase production costs, and achieve the effects of improving production efficiency, avoiding safety accidents, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

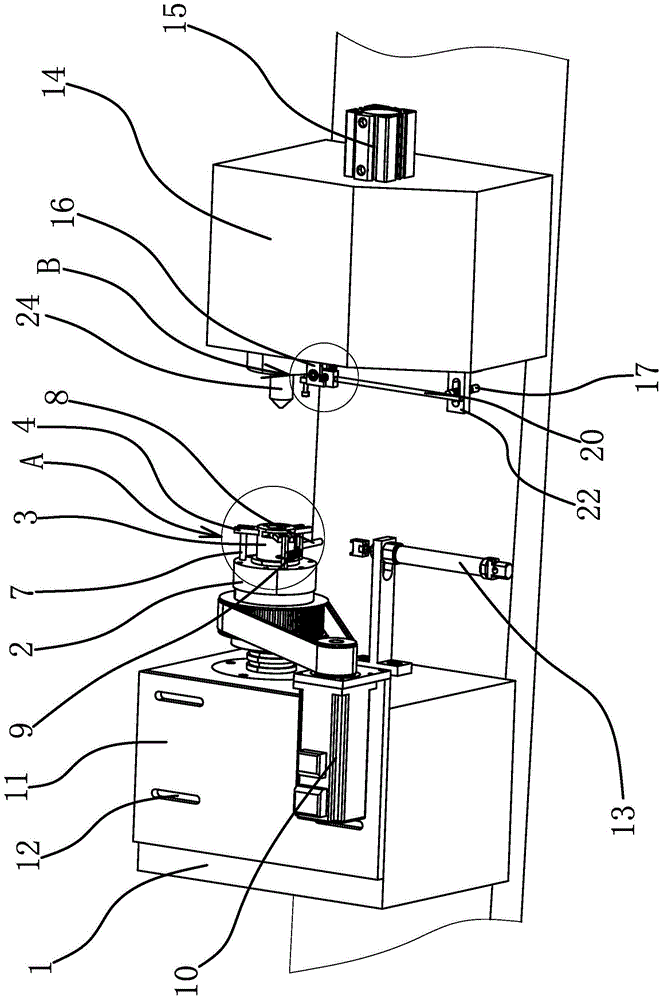

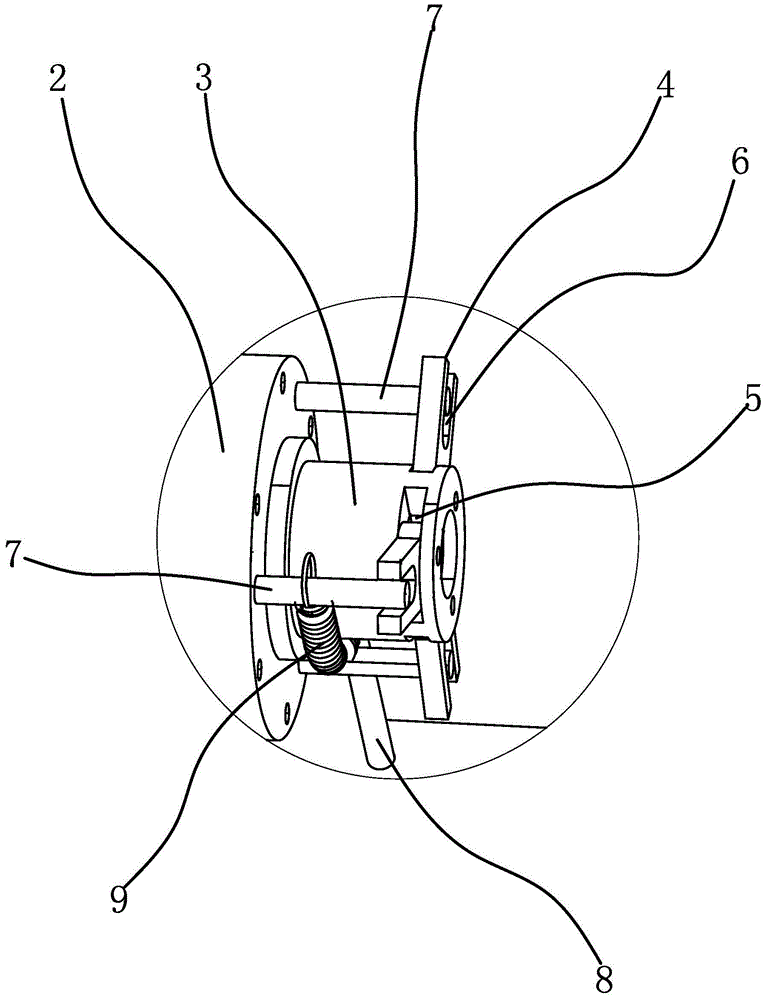

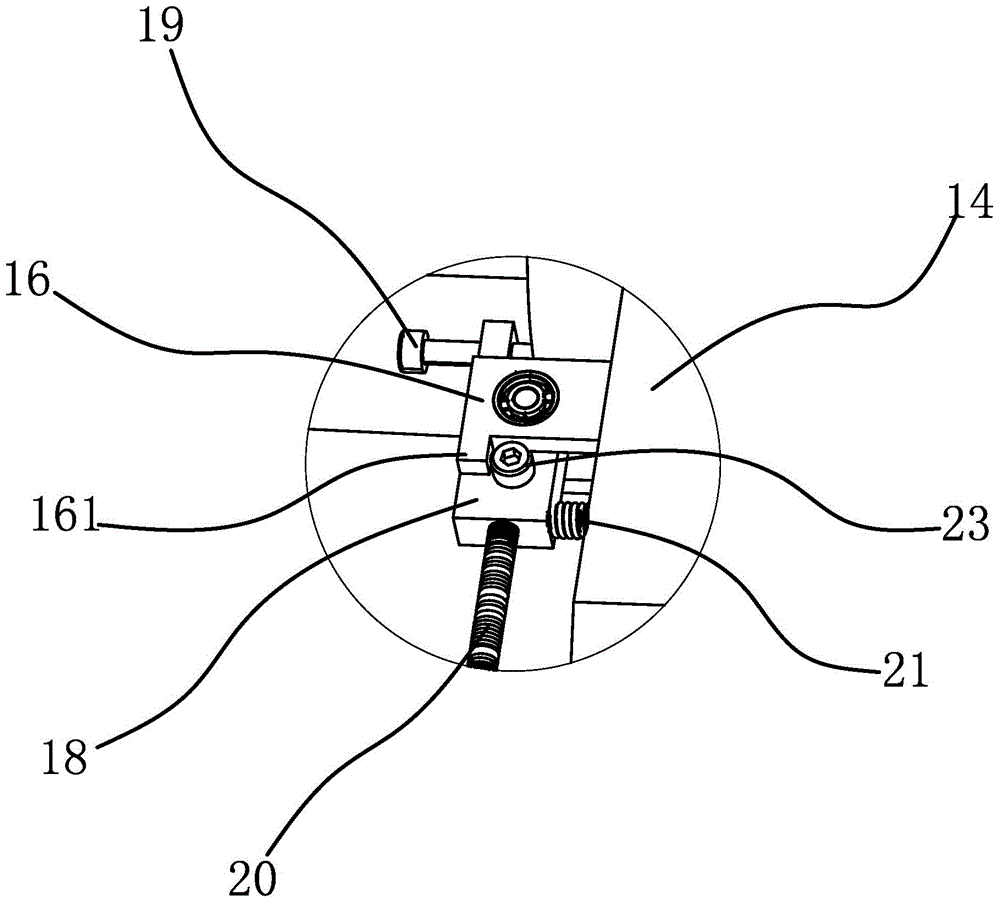

[0032]The clamping device includes a mounting base 1, a rotating head frame 2, a rotating cylinder 3, a clip 4, a clamping part 41, a through groove 5, an opening groove 6, a fixed shaft 7, a toggle member 8, a tension spring 9, a servo Motor 10, mounting plate 11, sliding hole 12, cylinder 13, tailstock 14, tailstock cylinder 15, bracket one 16, limit protrusion 161, bracket two 17, connecting plate 18, detection screw 19, adjusting rod 20, reset Spring 21, sensor 22, limit screw 23, thimble 24.

[0033] Specifically, as figure 1 As shown, the clamping device includes a mounting base 1 and a rotating head frame 2. The rotating head frame 2 is axially positioned on the mounting base 1 and can rotate circumferentially relative to the mounting base 1 driven by a driving source. The driving source is a servo motor 10 , the upper surface of the mounting base 1 is provided with a mounting plate 11, the mounting plate 11 is provided with a sliding hole 12, and the sliding hole 12 i...

Embodiment 2

[0041] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, the clamping reset member is a torsion spring, and the torsion spring is sleeved on the fixed shaft 7, and one end of the torsion spring It is fixed on the rotating head frame 2, and the other end of the torsion spring is fixed on the toggle member 8 by a steel wire stay cord, and the tightening direction of the torsion spring is the same as the rotation direction when the workpiece is processed.

Embodiment 3

[0043] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1. The difference is that in this embodiment, the driving part is a forward and reverse motor, and a push rod is fixedly connected to the motor shaft of the forward and reverse motor. The push rod can abut on the dial 8 and push the dial 8 to make the inner ends of the clips 4 away from each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com