Muscle driving module based on temperature responsiveness hydrogel

A temperature-responsive, driving module technology, applied in medical science, manipulators, prostheses, etc., can solve the problems that hydrogels can no longer achieve intelligent functions, limit hydrogels, etc., to avoid mechanical damage and easy to control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below with reference to the drawings and specific embodiments.

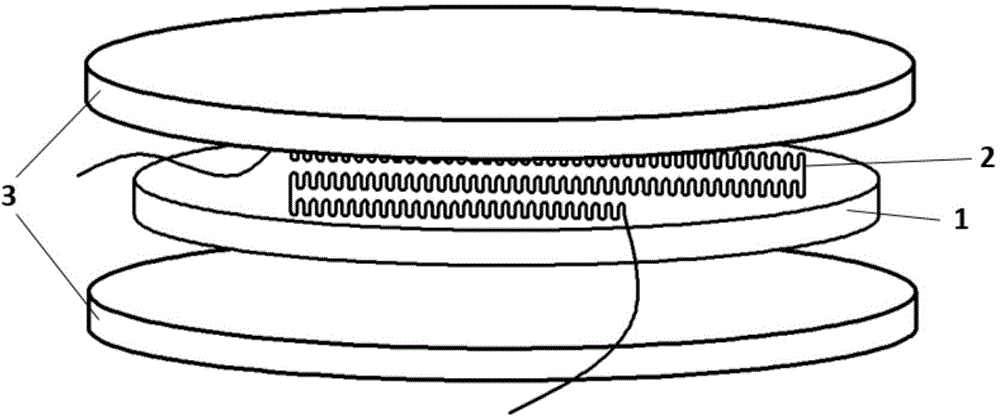

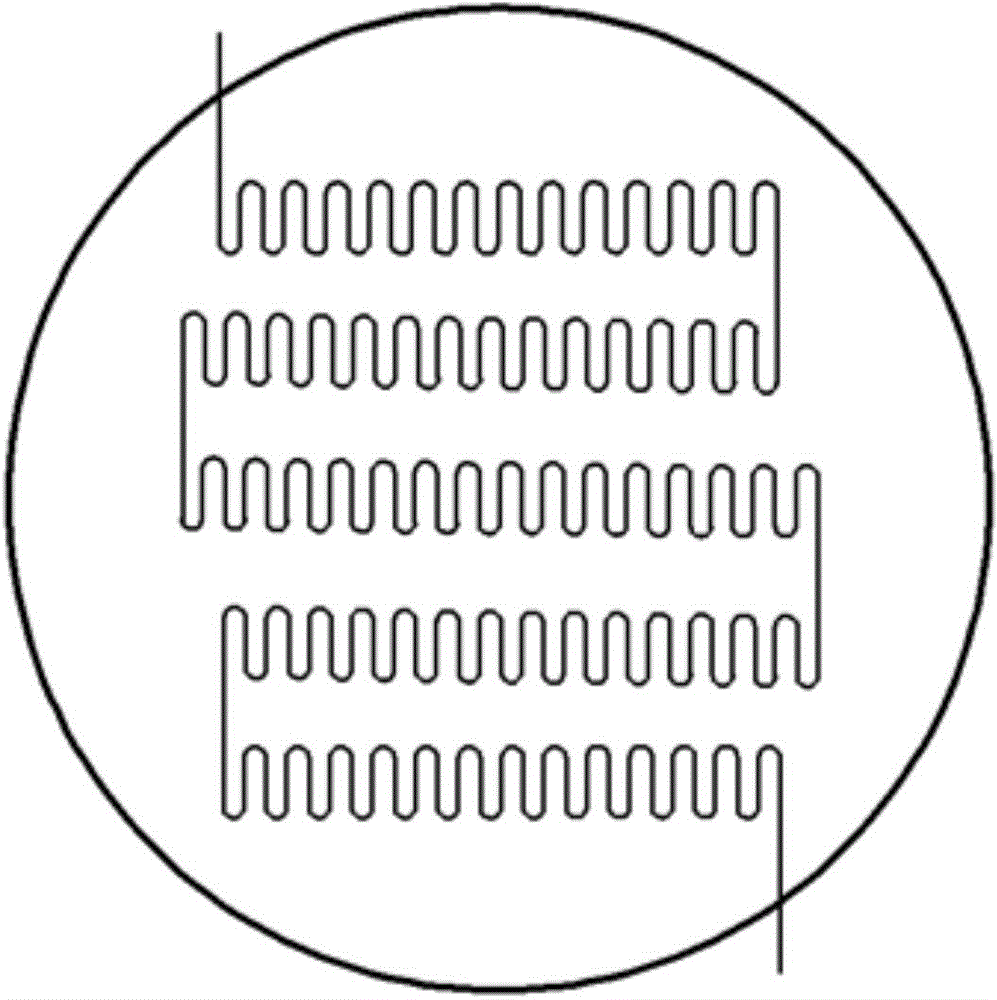

[0045] Such as figure 1 This embodiment is a schematic structural diagram of the muscle drive module based on temperature-responsive smart hydrogel (ie, temperature-responsive hydrogel), including temperature-responsive smart hydrogel interlayer 1 (ie, based on temperature-responsive hydrogel) The driving layer), the stretchable electric heating layer 2 attached to the temperature-responsive smart hydrogel interlayer, and the upper and lower layers of the flexible protective layer 3 in which the temperature-responsive smart hydrogel is wrapped.

[0046] The temperature-responsive hydrogel used to prepare the driving layer in this embodiment is as follows:

[0047] It includes a cross-linked first network monomer and a second network monomer, the network structure formed by the first network monomer is a flexible network and has temperature response characteristics...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com