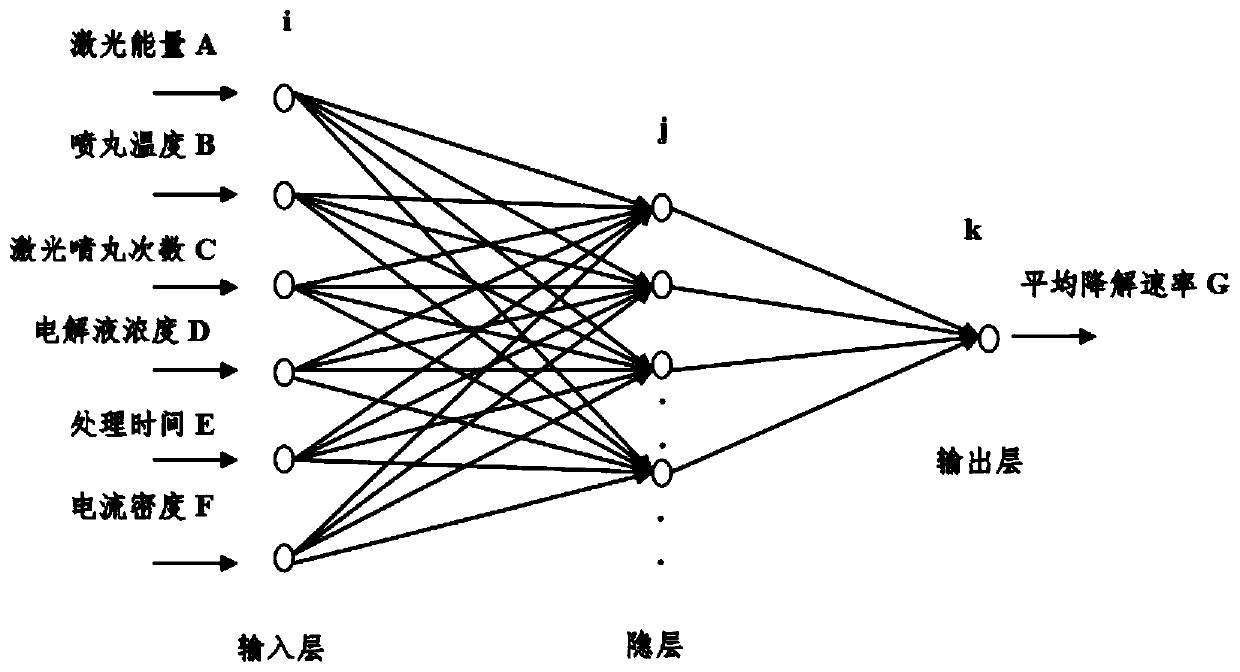

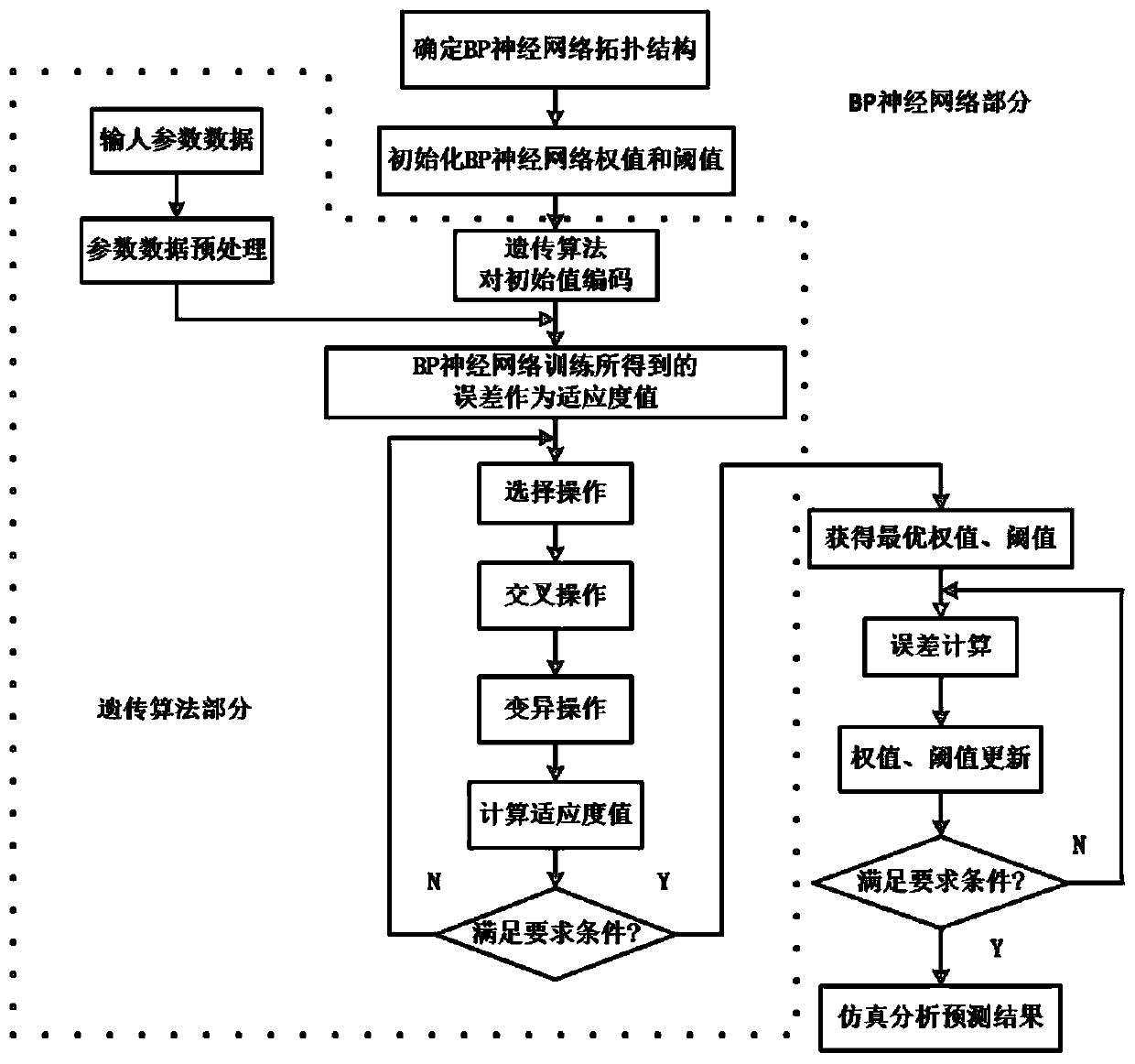

Method for controlling degradation rate of medical magnesium-based material composite biological coating

A biological coating and degradation rate technology, applied in coatings, neural learning methods, biological neural network models, etc., can solve problems such as unpredictable degradation rates, achieve good intelligent characteristics, simplify prediction and control processes, and realize analysis and predicted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

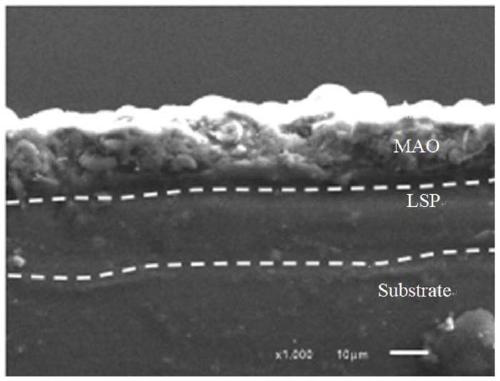

[0055] (1.1) Preparation of LSP coating: adopt the parameter values of laser energy, shot-peening temperature, laser shot-peening number of times determined in step 6, adopt laser to carry out laser shock on the surface of magnesium-based material, prepare LSP on the surface of magnesium-based material coating samples;

[0056] (1.2) Preparation of LSP / MAO composite biological coating: take the LSP coating sample prepared in step (1.1) as the basic sample; select sodium silicate, sodium fluoride, potassium hexafluorotitanate, hydroxyapatite and ethylene glycol are electrolyte components, where Na 2 SiO 3 9H 2 O: 12g / L, NaF: 5g / L, K 2 TiF 6 : 2g / L, HA nanoparticles (20nm): 3g / L, ethylene glycol: 10ml / L; adjust the pH value of the electrolyte to 12 with NaOH; adopt the current density, treatment time and electrolyte concentration determined in step 6 Parameter value, prepare LSP / MAO composite biological coating on the surface of LSP coating sample;

[0057] (1.3) The out...

specific Embodiment

[0062] A hot-rolled AZ80 magnesium alloy plate of 60mm×20mm×2mm was selected as the substrate for surface modification treatment, and the substrate was polished with abrasive paper to ensure a certain surface toughness. Subsequently, the samples were ultrasonically degreased in ethanol for 10 min, washed with distilled water, and dried naturally in air.

[0063] Use the above-mentioned pretreated magnesium alloy substrate to prepare the LSP coating, and use the YAG laser to modify the surface of the substrate with LSP. The process parameters of the YAG laser are set as follows: laser energy A is 2J, and shot peening temperature B is 120°C , the number C of laser peening is 3 times, the wavelength is 1064nm, the pulse width is 20ns, the spot diameter is 3mm, and the overlap rate is 50%. Use water with a thickness of about 1mm as a transparent cover, and use professional aluminum foil with a thickness of 0.1mm as an absorbent cover to protect the substrate surface from thermal e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com