A method of sealing micro heat pipe perfusion hole with low melting point alloy

A low-melting-point, micro-heat pipe technology, applied in the process of producing decorative surface effects, micro-structure technology, indirect heat exchangers, etc., can solve problems such as micro-heat pipe failure, product application problems, and vacuum degree drop in the tube, to achieve Extend the effect of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

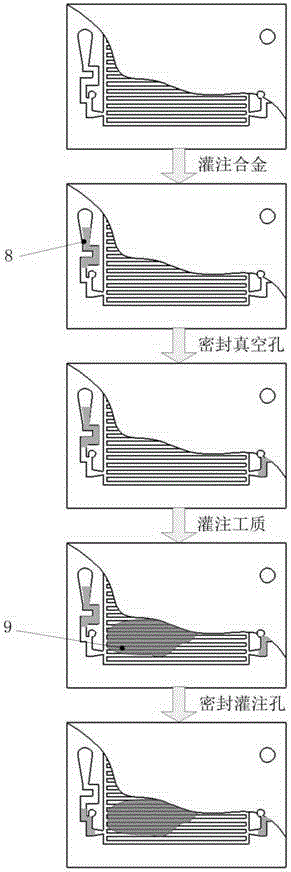

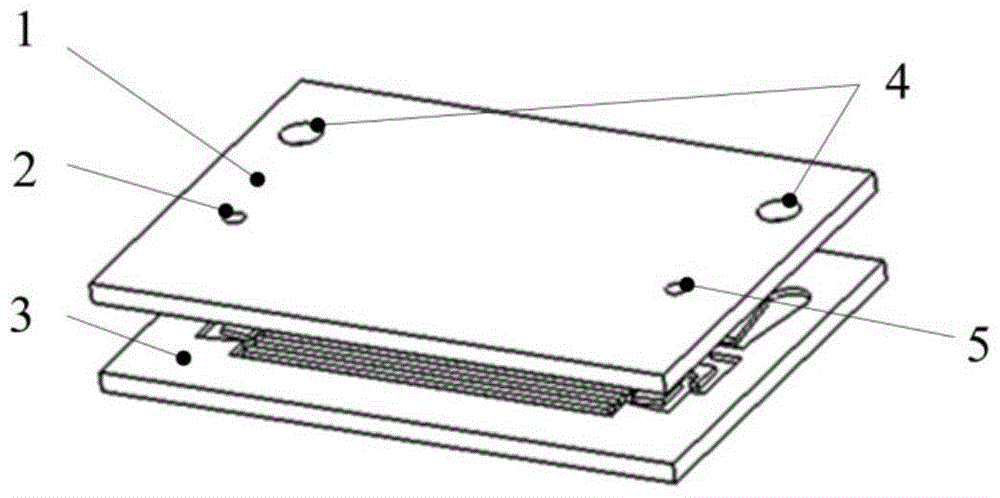

[0020] First, the glass cover plate and the silicon substrate are sealed together by anodic bonding, wherein the etching depth of the phase change channel and the perfusion channel on the silicon substrate is 150 μm to form a silicon-based micro heat pipe 13 .

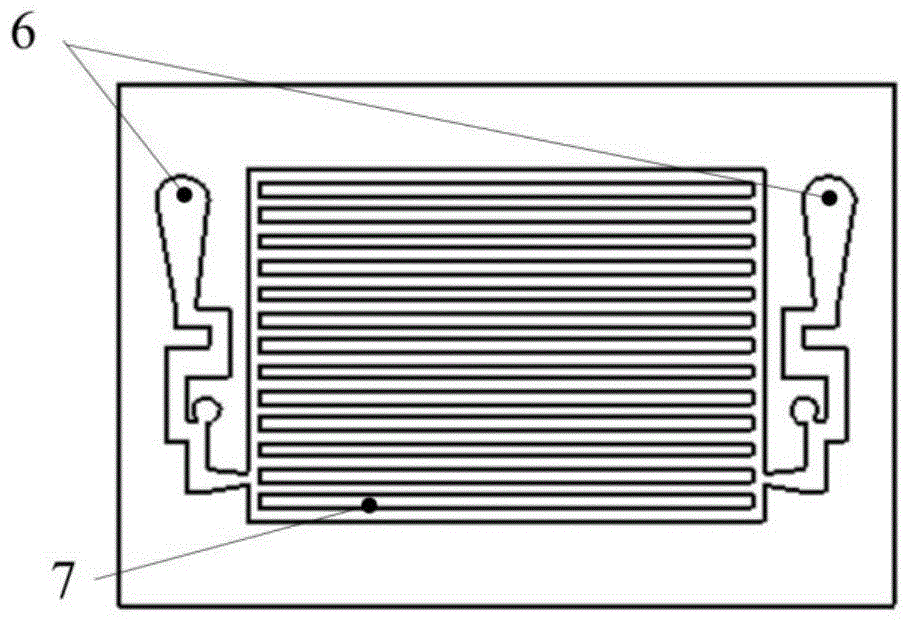

[0021] In the second step, the silicon-based micro heat pipe is placed on the hot plate 14, and the temperature of the hot plate 14 is controlled to be 5° C. higher than the melting point of the low melting point alloy (the melting point of the low melting point alloy is 120° C.). A certain amount of liquid low melting point alloy is injected into the two pouring channels 6 through the low melting point alloy filling hole 4, and the silicon-based micro heat pipe is removed from the hot plate 14, and the low melting point alloy in the tube is cooled and solidified.

[0022] The third step is to connect the silicon-based micro heat pipe 13 to the vacuum filling circuit for vacuuming operation; after reaching the predeterm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com