Carboxyl group-containing modified amino sulfonate high efficiency water reducer preparation method

A technology of sulfamate and high-efficiency water reducer, which is applied in the field of concrete materials, can solve the problems of complex molecular structure and high production cost of high-efficiency water reducer, so as to overcome easy bleeding, reduce investment in production equipment and fixed assets, and reduce The effect of lead time on production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

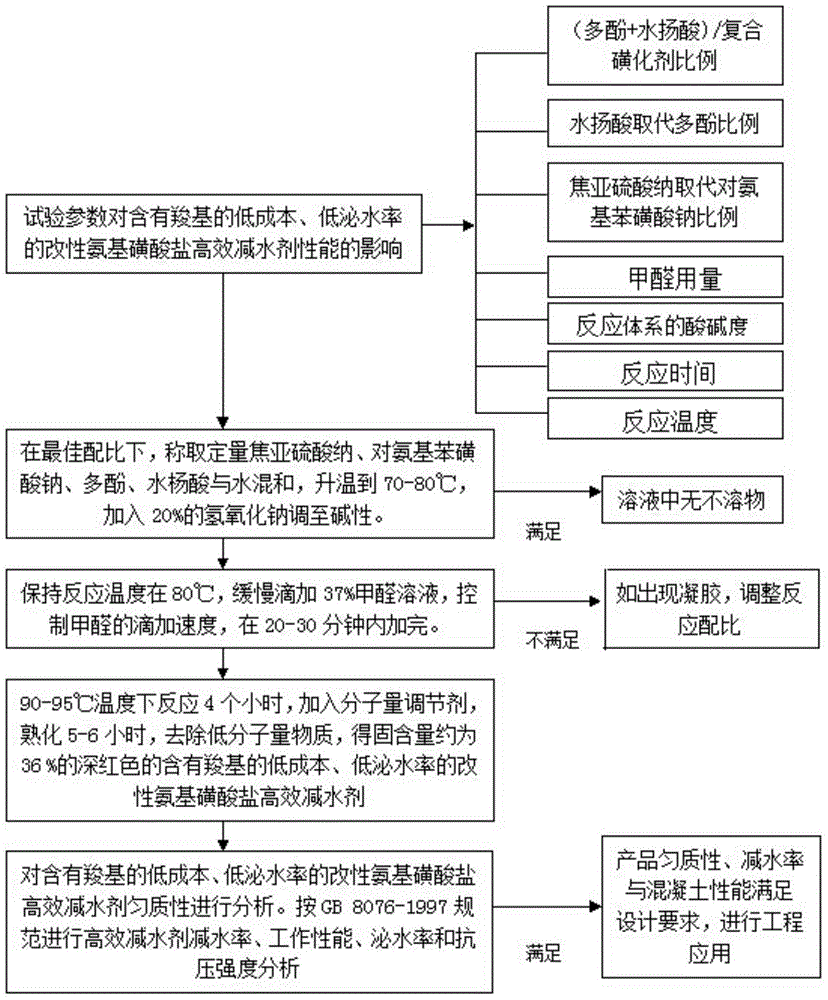

[0024] A preparation method of a carboxyl-containing modified sulfamate high-efficiency water reducer, comprising the following steps:

[0025] Step 1, adding sodium metabisulfite, sodium p-aminobenzenesulfonate, bisphenol A, and salicylic acid into water in a mass ratio of 1.5-2:6.5-6.75:5.5-6:1, stirring and dissolving in order to form a uniform solution;

[0026] Step 2, heating the mixed solution to 70-80°C, adding 20wt% sodium hydroxide solution to adjust the pH value of the reaction system to 10-11, ensuring that no solution is produced in the solution;

[0027] Step 3, slowly drop formaldehyde solution into the solution in step 2, the mass concentration of formaldehyde is 37%, control the drop rate of formaldehyde to finish adding dropwise within 20-30 minutes, then heat up to 90°C-95°C to react, react The time is 4 to 5 hours. After the reaction is completed, urea is added to remove the residual formaldehyde in the solution, and then cooled to room temperature;

[002...

Embodiment 1

[0031] Accurately weigh 30kg of sodium pyrosulfite, 130kg of sodium p-aminobenzenesulfonate, 110kg of bisphenol A, and 20kg of salicylic acid solids into a reaction kettle equipped with a stirrer, a thermometer, a dropping funnel and a reflux condenser, and then add 540 kg of water . Start the stirrer and stir at a speed of 180 rpm to completely dissolve the solid sodium pyrosulfite, sodium p-aminobenzenesulfonate, bisphenol A, and salicylic acid in water to form a uniform solution. The temperature of the mixed solution was slowly raised to 70° C., and the pH value of the reaction system was adjusted to 10-11 with 20% sodium hydroxide solution. Keep the temperature of the reaction solution at 80° C., slowly add 160 kg of formaldehyde solution (37 wt % concentration) dropwise, and control the addition of the formaldehyde solution within 20 minutes. Then the temperature of the solution was raised to 90° C. and reacted for 4 hours. After the reaction, a small amount of urea was...

Embodiment 2

[0033] Accurately weigh 40kg of sodium metabisulfite, 135kg of sodium p-aminobenzenesulfonate, 120kg of bisphenol A, and 20kg of salicylic acid solids into a reaction kettle equipped with a stirrer, a thermometer, a dropping funnel and a reflux condenser, and then add 550 kg of water . Start the stirrer and stir at a speed of 180 rpm to completely dissolve the solid sodium pyrosulfite, sodium p-aminobenzenesulfonate, bisphenol A, and salicylic acid in water to form a uniform solution. The temperature of the mixed solution was slowly raised to 80° C., and the pH value of the reaction system was adjusted to 10-11 with 20% sodium hydroxide solution. Keep the temperature of the reaction solution at 80° C., slowly add 160 kg of formaldehyde solution (37 wt % concentration) dropwise, and control the addition of the formaldehyde solution within 20 minutes. Then the temperature of the solution was raised to 90° C. and reacted for 5 hours. After the reaction, a small amount of urea w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com