Method for high-selectivity R142b cracking preparation of vinylidene fluoride

A vinylidene fluoride, high-selectivity technology, applied in the field of high-selectivity R142b pyrolysis to prepare vinylidene fluoride, can solve the problems of increasing the difficulty of controlling the temperature of the rectification tower, cracking gas with many impurities, and difficult removal, etc., to achieve the goal of reducing impurities Produce, reduce difficulty, increase selectivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

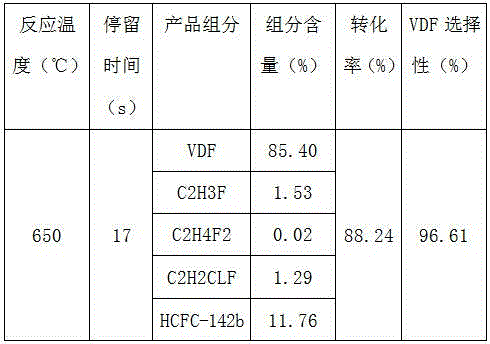

Embodiment 1

[0012] A set of production capacity of 2000t / a vinylidene fluoride production cracker.

[0013] Raise the temperature of the cracking furnace to 650°C. After the temperature of the cracking furnace is uniform and stable, control the pressure of the raw material buffer tank to 0.22MPa by controlling the steam inlet valve of the raw material buffer tank, and at the same time control the discharge regulating valve of the raw material buffer tank so that the flow rate of the raw material is 15m3 / h The speed enters the cracking furnace for the cracking reaction, and the residence time of the raw material in the cracking tube is 17s. After the reaction was stable, the post-reaction cracked gas was taken for analysis. The analysis results are as follows:

[0014]

[0015] By controlling the reaction temperature and the residence time of raw materials, the present invention greatly increases the selectivity of the reaction without reducing the conversion rate, reduces the generati...

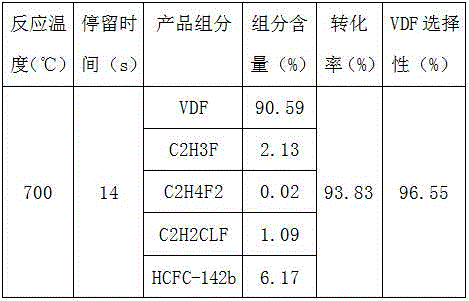

Embodiment 2

[0017] A set of production capacity of 2000t / a vinylidene fluoride production cracker.

[0018] Raise the temperature of the cracking furnace to 700°C. After the temperature of the cracking furnace is uniform and stable, control the pressure of the raw material buffer tank to 0.28MPa by controlling the steam inlet regulating valve of the raw material buffer tank, and at the same time control the discharge regulating valve of the raw material buffer tank so that the flow rate of the raw material is 18m3 / h The speed enters the cracking furnace for the cracking reaction, and the residence time of the raw material in the cracking tube is 14s. After the reaction was stable, the post-reaction cracked gas was taken for analysis. The analysis results are as follows:

[0019]

[0020] By controlling the reaction temperature and the residence time of raw materials, the present invention greatly increases the selectivity of the reaction without reducing the conversion rate, reduces t...

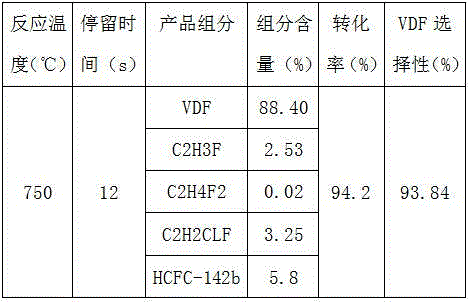

Embodiment 3

[0022] A set of production capacity of 2000t / a vinylidene fluoride production cracker.

[0023] Raise the temperature of the cracking furnace to 750°C. After the temperature of the cracking furnace is uniform and stable, control the pressure of the raw material buffer tank to 0.25MPa by controlling the steam inlet valve of the raw material buffer tank, and at the same time control the discharge regulating valve of the raw material buffer tank so that the flow rate of the raw material is 20m3 / h The speed enters the cracking furnace for the cracking reaction, and the residence time of the raw material in the cracking tube is 12s. After the reaction was stable, the post-reaction cracked gas was taken for analysis. The analysis results are as follows:

[0024]

[0025] By controlling the reaction temperature and the residence time of raw materials, the present invention greatly increases the selectivity of the reaction without reducing the conversion rate, reduces the generati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com