On-line coal quality property detection device

A detection device and characteristic technology, applied in the field of spectral diagnosis and measurement, can solve problems such as poor precision and accuracy, uneven measurement surface of accumulated particles, unstable interaction process between laser and solid particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings.

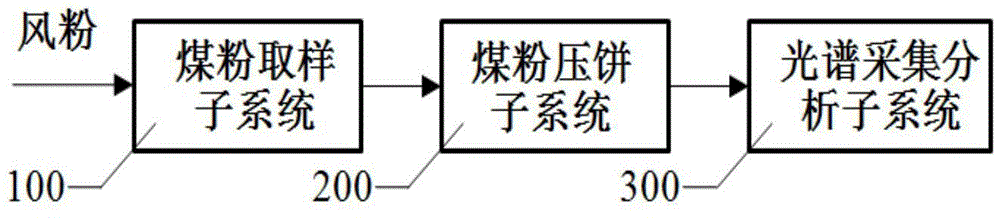

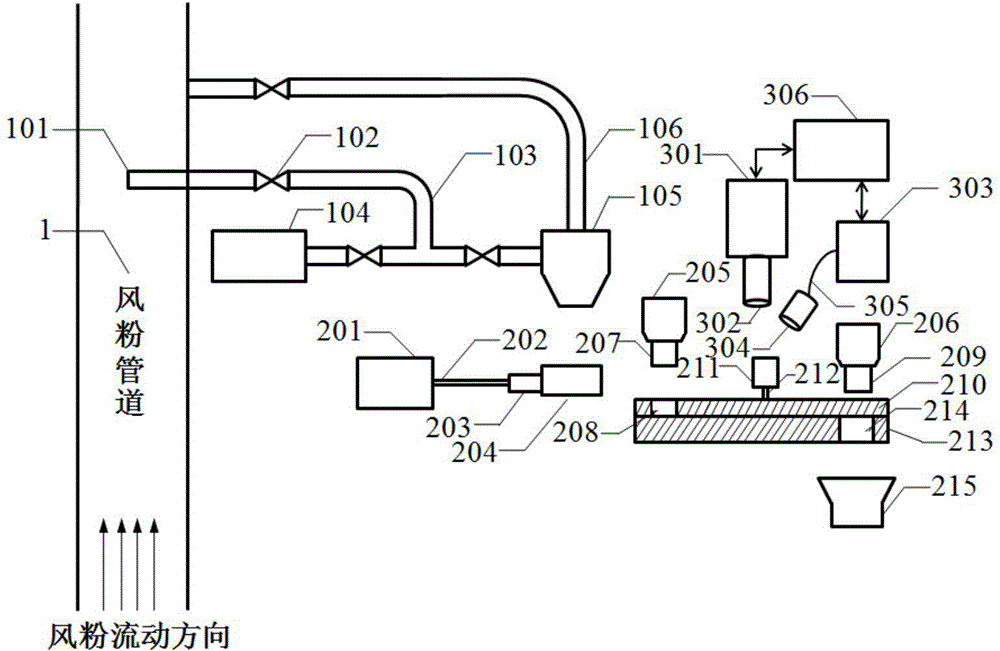

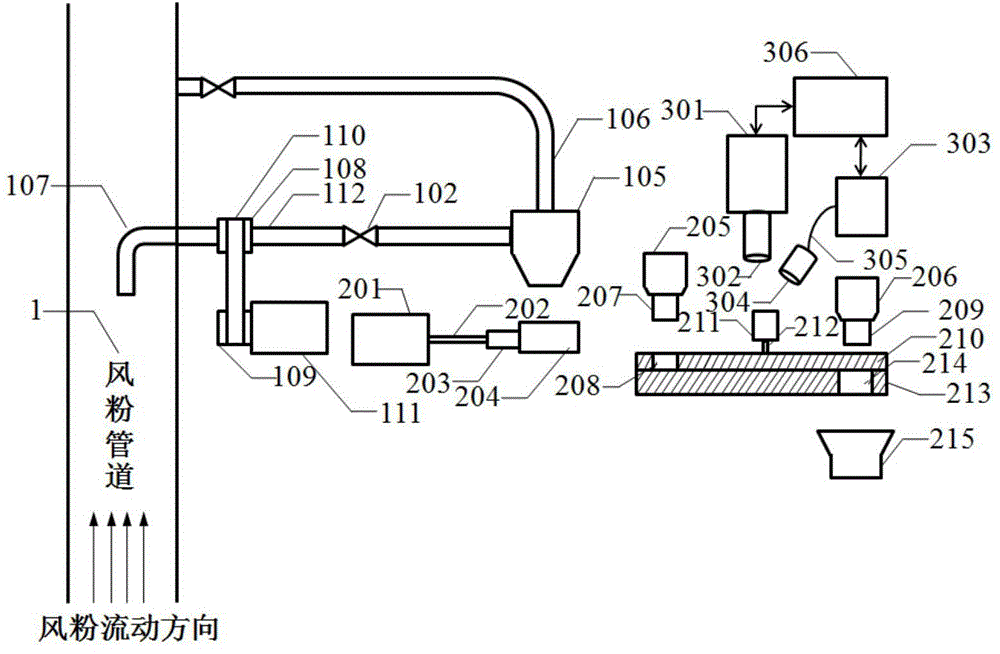

[0062] as attached figure 1 As shown, an online detection device for coal quality characteristics includes a pulverized coal sampling sub-system 100 , a pulverized coal cake pressing sub-system 200 and a spectrum acquisition and analysis sub-system 300 .

[0063] The pulverized coal sampling sub-system 100 adopts one of the following methods or a combination of any two or more of the following methods to realize the sampling from the vertical air powder pipeline 1 installed between the coal pulverizer outlet and the burner inlet of the coal-fired power generation unit. To obtain coal powder of low-rank coal:

[0064] a. Sampling by negative pressure suction;

[0065] b. Sampling by wind powder flow;

[0066] c. Sampling by manipulator.

[0067] as attached Figure 2a , 2dAs shown, the pulverized coal sampling system utilizing negative pressure suction to sample i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com