Method for obtaining material thermo-optical coefficient through measuring light spot radius change

A technology of thermo-optic coefficient and spot radius, which is applied in the direction of material analysis, measuring devices, and analyzing materials through optical means, can solve the problems of high price, high cost of measurement, and increased cost of measurement methods, and achieve low measurement cost, Simple and accurate results obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

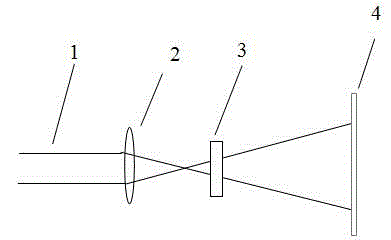

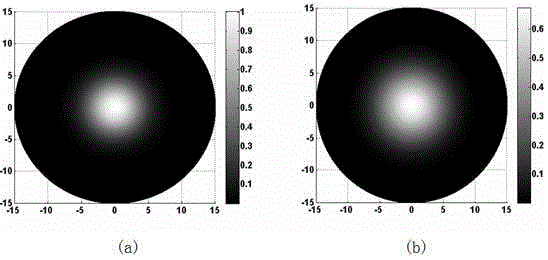

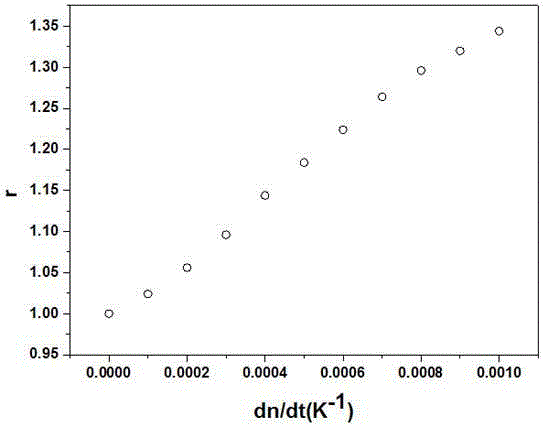

[0019] Embodiment 1: A method for obtaining the thermo-optical coefficient of a material by measuring the change in the radius of the spot, using a continuous Gaussian laser beam as incident light, converging on the sample to be tested by a convex lens, so that the sample to be tested produces a thermal lens effect. The sample to be tested is at a certain distance in front of or behind the focal point of the convex lens in the optical path. After the pulsed laser emitted from the laser is converged by the convex lens, it acts on the sample to be tested near the focal point. After passing the sample, the far-field position of the sample is measured after the sample is measured. Material thermo-optical coefficient, the specific measurement steps are:

[0020] (1) Place the sample to be tested at a position away from the focus of the convex lens, receive the far-field spot and measure the size of the far-field spot;

[0021] (2) Place the sample to be tested at a certain distance near...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com