A device for adjusting coherence factor in lithography illumination system

A lighting system and coherence factor technology, applied in the field of lithography, can solve the problems of large zoom ratio of the zoom lens group, affecting the transmittance of the system, increasing the difficulty of design, etc., achieving fast adjustment speed, large adjustment range, and space saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

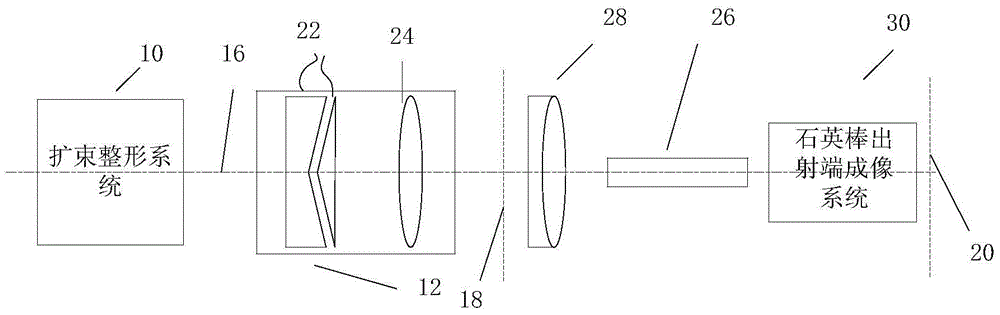

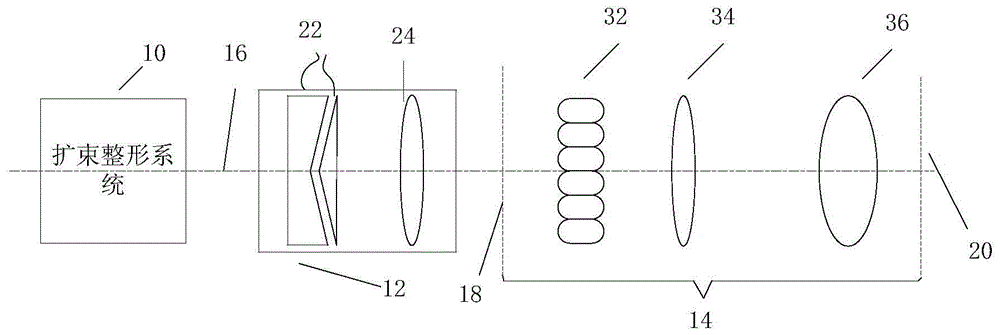

[0036] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

[0037] The invention can realize multi-level coherence factor conversion with a simple method, improve the transmittance of the lighting system, and improve the exposure efficiency.

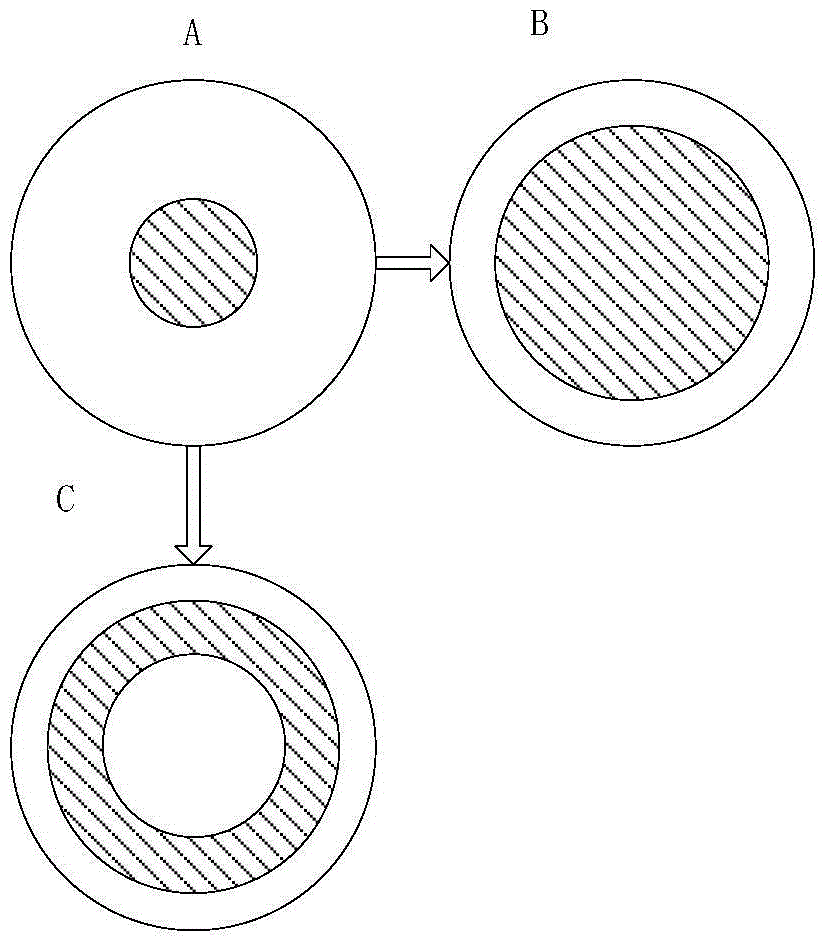

[0038] The present invention first utilizes two groups of reflector groups, and controls each reflector to form the same angle with the optical axis through a rotating motor, and adjusts the numerical aperture of the light beam to adjust the coherence factor of the lighting system. The numerical aperture can be continuously adjusted, that is, the continuous coherence factor. Then use the tapered prism to change the overall height of the light beam, and increase the adjustable range of the coherence factor without adjusting the mirror group. Compared with adjusting the coherence factor of the lighting system only through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com