A cylinder sleeve to be inserted into an engine block and an engine block

A cylinder liner and body technology, applied in the direction of machines/engines, cylinders, cylinder heads, etc., can solve the problem that diffusion cannot occur properly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

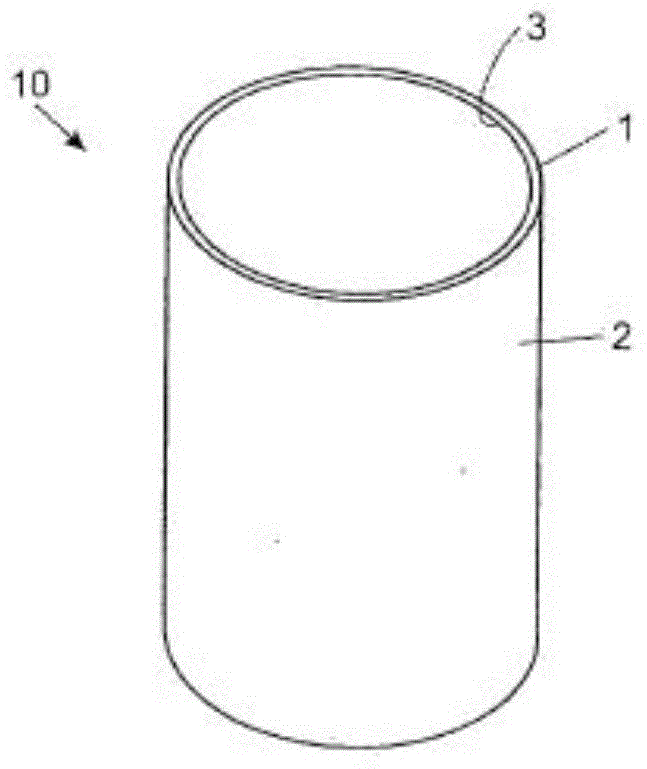

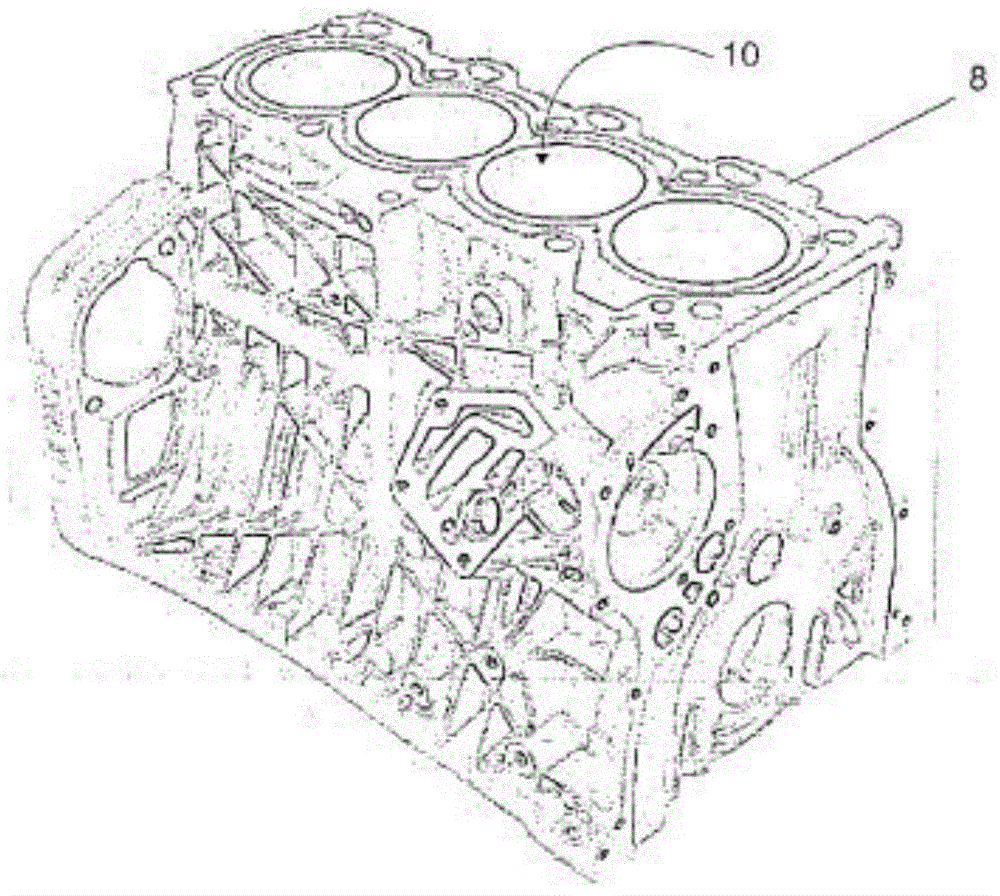

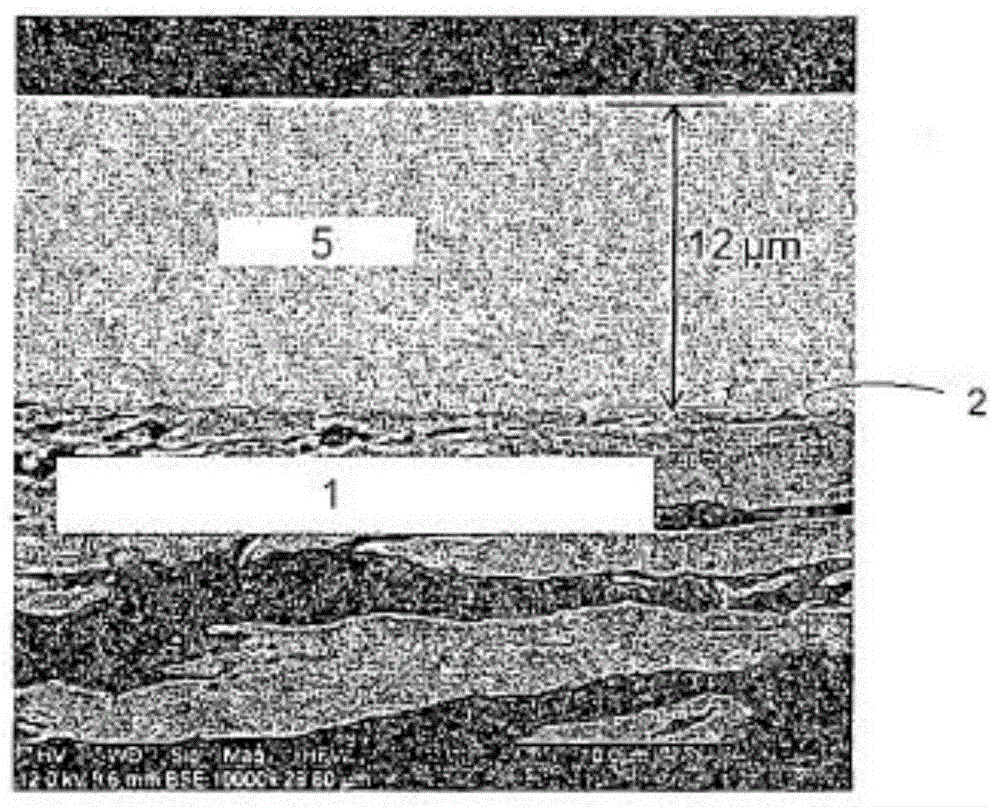

[0039] The field of the invention relates to internal combustion engines, in particular to the interaction between the cylinder liner 10 and the corresponding block 8 . By casting / spraying liquid metal around a cylinder sleeve 10 previously arranged in a corresponding mould, one realizes the body with the sleeve 10 inserted. Typically, the metal of the airframe is a light metal such as aluminum or an aluminum alloy.

[0040] As stated, the cylinder sleeve 10 needs to ensure that it adheres to the block 8 and that no empty areas 15 without metal (casting defects) occur after the liquid metal casting in the mold has cooled. As explained in the prior art, ensuring this combination is relatively complex.

[0041] In order to properly understand the present invention, some concepts and examples need to be clarified. As defined above, there are two casting types for inserting cylinder sleeves into blocks made of aluminum alloys. That is, high pressure die casting (hereinafter ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com