Coupling type inertial cyclone fluid particle heterogeneous separation device and method

A technology of separation device and cyclone separator, which is applied in the direction of the cyclone device and the device in which the axial direction of the cyclone can be reversed, etc., which can solve the problems of long separation distance and time, large penetration of solid phase particles, etc. Achieve the effect of reducing design and manufacturing difficulty, reducing research and development time and costs, and improving processing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific implementation examples.

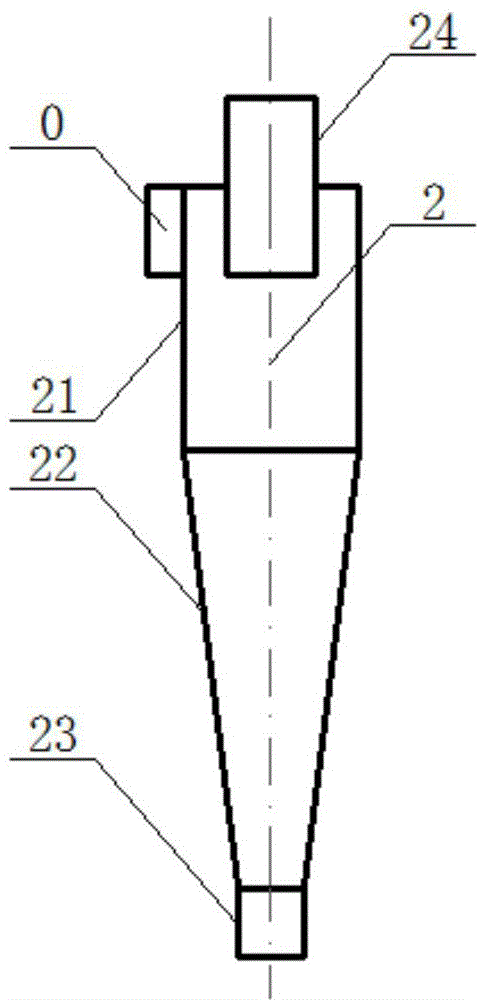

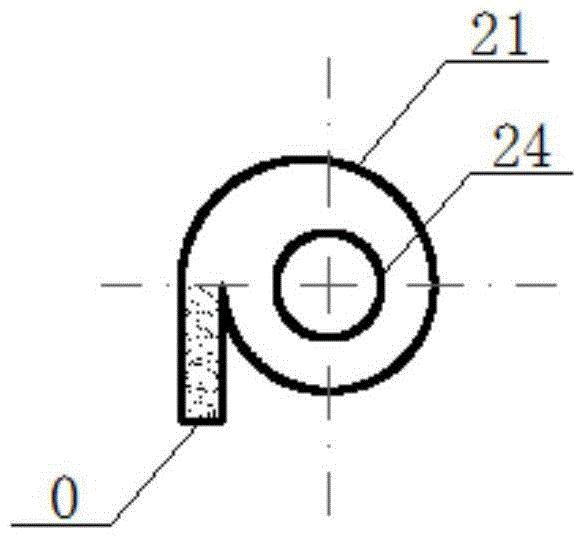

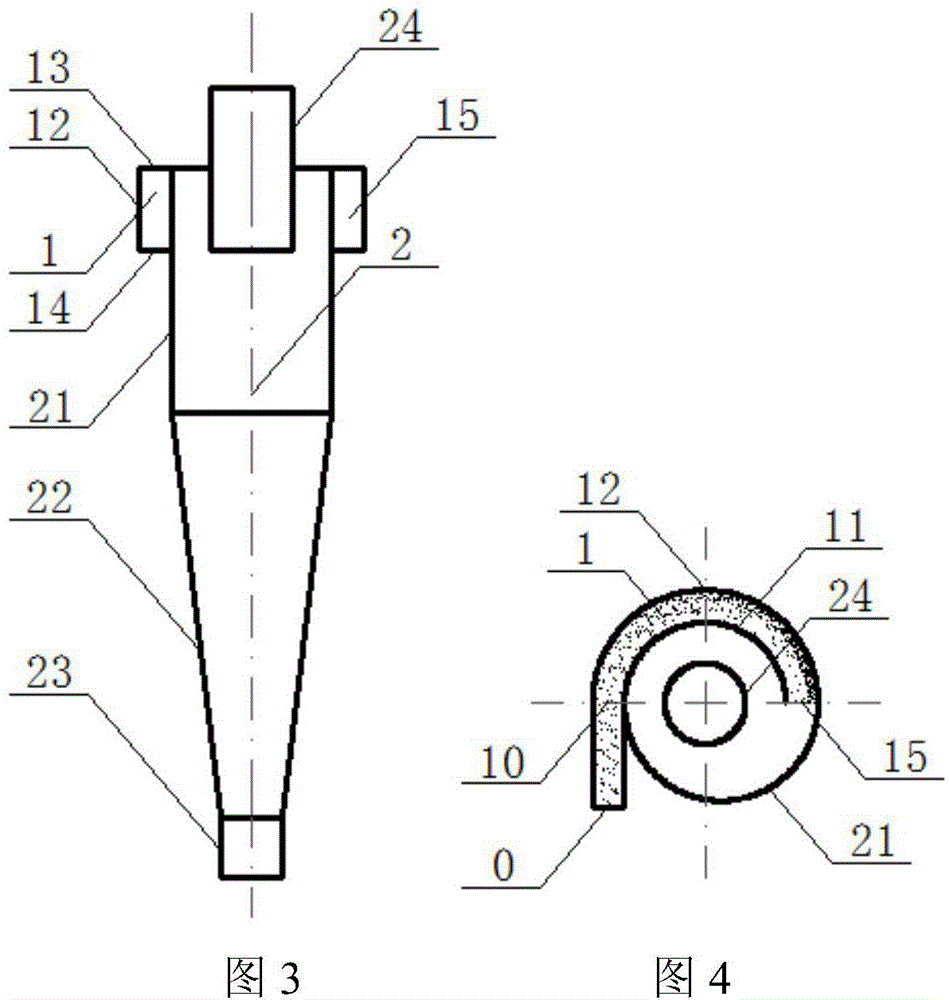

[0026] Such as image 3 , as shown in 4, a coupled inertial cyclone fluid particle heterogeneous phase separation device, including an inertial bend 1 and an integrated volute tangential inlet cyclone separator 2 coupled with it and its connected components Barrel 21 , cone 22 , particle outlet 23 and fluid outlet 24 .

[0027] The inertia bend 1 adopts a one-way connection mode, and its inlet 10 is connected to the external pipeline 0, and its outlet 15 is connected to the inlet port 20 of the volute of the cyclone separator. The inertia curve 1 is composed of the concentric fan-shaped annular space enclosed by the inner arc plate 11, the outer arc plate 12, the upper top plate 13 and the lower bottom plate 15, wherein the inner arc plate 11 is the cylinder 21 of the cyclone separator. Project the coincidence structure for the space. The connection can be we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com