Subpackage valve used for controlling powder subpackage quality

A packaging and quality technology, applied in the field of mechanical valve devices, can solve the problems of affecting the packaging accuracy, low packaging accuracy, abnormal powder leakage, etc., and achieve the goal of improving measurement accuracy, improving work efficiency and shortening working hours Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

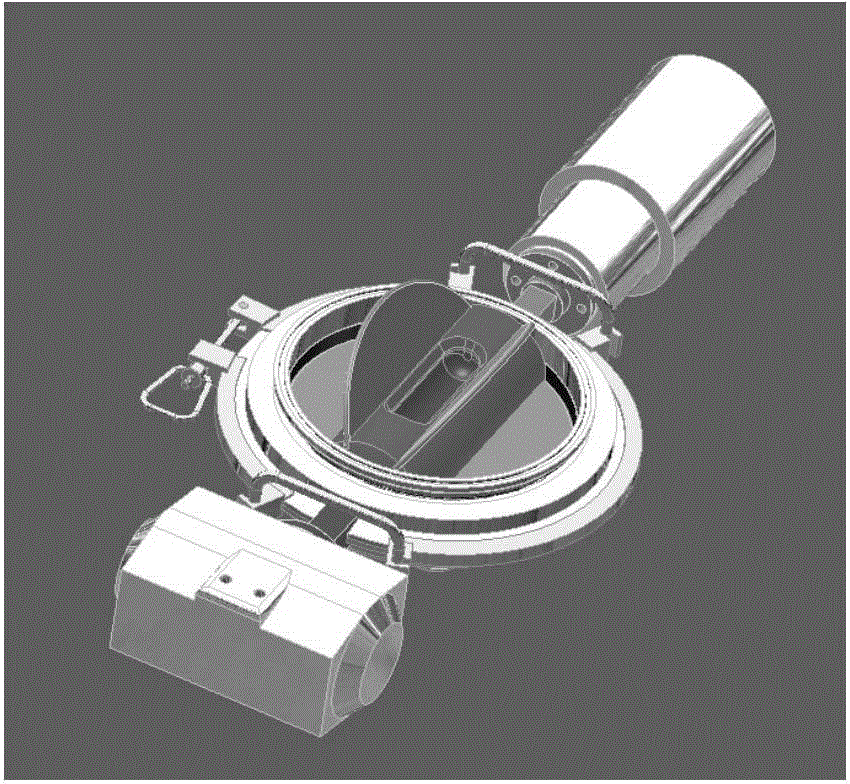

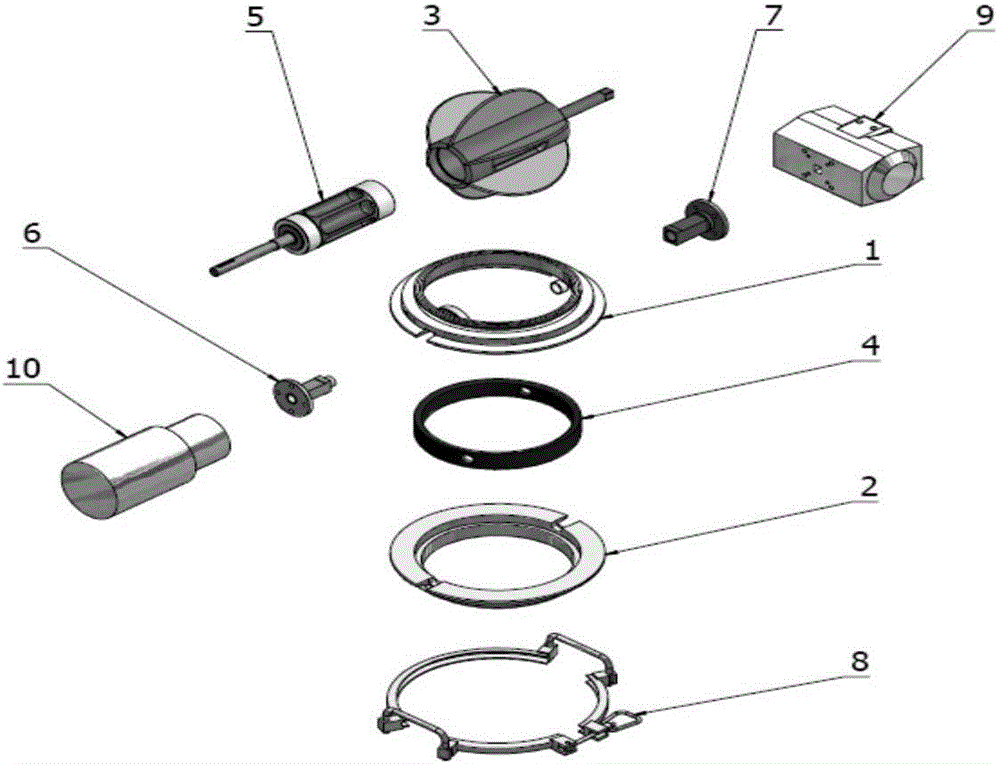

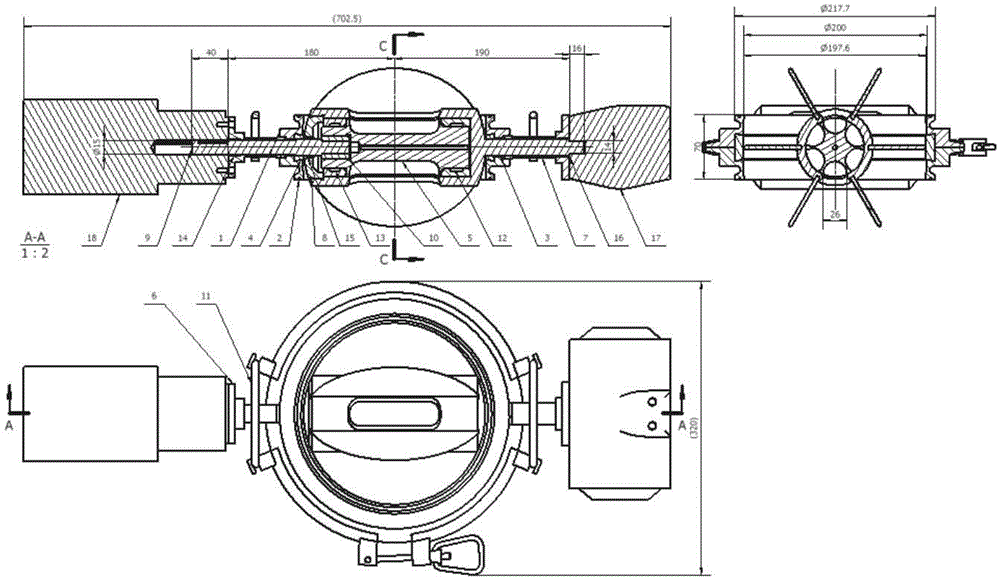

[0031] To prepare the sub-packaging valve for controlling the powder sub-packaging quality of the present invention, the upper connecting valve seat 1, the lower connecting valve seat 2, the valve disc and the outer valve core 3, the main sealing ring 4, the inner valve core 5, the inner valve core rotating shaft The support frame 6 and the outer valve core drive support 7, 6, and 7 jointly fix the pneumatic actuator to ensure the overall stability of the valve, no resonance, and to ensure the safe and smooth operation of the system: the clamp part 8, the pneumatic actuator 9 and the air motor 10 composition.

[0032] The upper connection valve seat 1 is connected with the discharge end pipeline of the vacuum feeder through a clamp, which is easy to install and disassemble, the connection is firm, and the sealing performance is reliable; the lower connection valve seat 2 is connected to the isolator or the feed of the reactor The end pipes are connected by flanges, which are e...

Embodiment 2

[0033] Example 2 Controlling the use experiment of powder sub-packaging quality

[0034]The use of the dispensing valve for controlling the quality of powder dispensing is used to control the quality of powder dispensing. The experiment includes the steps of: controlling the dispensing valve by the main line PLC; after the vacuum feeder is discharged, the valve is used for metering control. , The weight of the material is checked by the weighing scale; PLC control opens 9,10 pneumatic actuators and pneumatic motors to drive 3 valve discs and outer valve cores. The star-shaped valve disc can perform 180° reciprocating motion in both forward and reverse directions to release the material evenly. During each 180° rotation, the valve disc is always kept on the 180° horizontal plane, separating the material in the front and rear. A large dose of powder material is dropped in different processes; the PLC considers the set blanking time according to the sub-packaging amount, and when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com