Fully autonomous maintenance equipment for tunnel concrete lining and its application method

A concrete and lining technology, which is applied in the field of fully independent maintenance equipment for tunnel concrete lining, can solve the problems of insufficient maintenance of primary concrete and secondary lining concrete, damage to the surface integrity of the surface layer, and failure to ensure uniform watering, etc., to improve the appearance quality , Avoid the risk of high-altitude operations and reduce the cost of maintenance procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

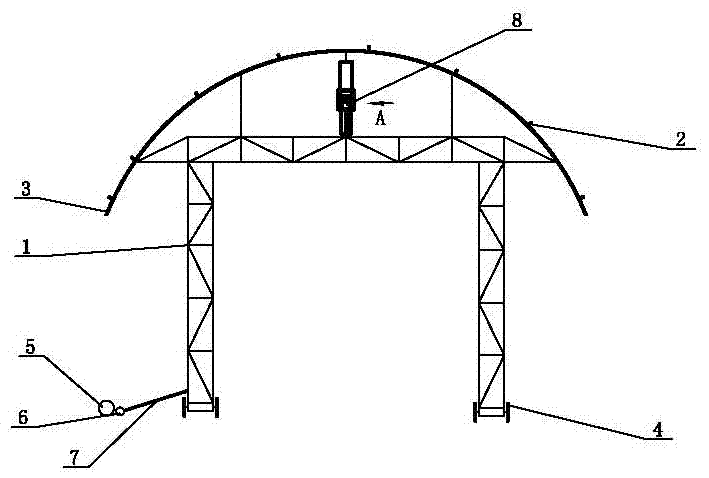

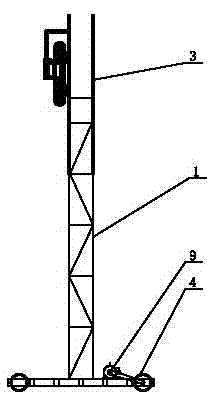

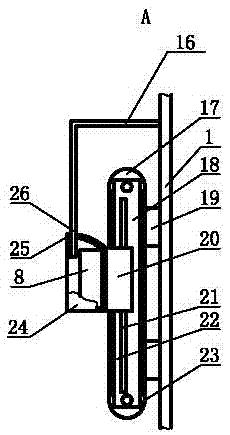

[0013] Fully autonomous maintenance equipment for tunnel concrete lining, such as figure 1 , figure 2 and image 3 As shown, it includes a maintenance platform 1, a controller 5, a water spray device and a distribution box 14, and the water spray device is composed of a booster pump 6, a water spray pipe 3 and an atomizing nozzle 2, and the water spray pipe 3 is Arc-shaped steel pipes, 5-10 atomizing nozzles 2 are arranged on each arc-shaped steel pipe, a running device and a controller 5 are installed on the lower part of the maintenance platform 1, and two rows of parallel arc-shaped water spray pipes 3 are installed on the upper part of the maintenance platform 1. Several atomizing nozzles 2 are set on the water pipe 3. The traveling device is composed of a traveling wheel 4 and a traveling motor 9. The traveling wheel 4 is installed on the lower part of the maintenance platform 1, and the traveling wheel 4 is connected to the traveling motor 9. The booster pump 6 passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com