Full-automatic spraying curing equipment for tunnel and control system of full-automatic spraying curing equipment

A control system and fully automatic technology, applied in tunnels, tunnel linings, mining equipment, etc., can solve the problems of insufficient maintenance of primary concrete and secondary lining concrete, damage to the surface integrity of the surface layer, and failure to ensure uniform watering, etc., to achieve Effects of improving appearance quality, reducing maintenance process costs, and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

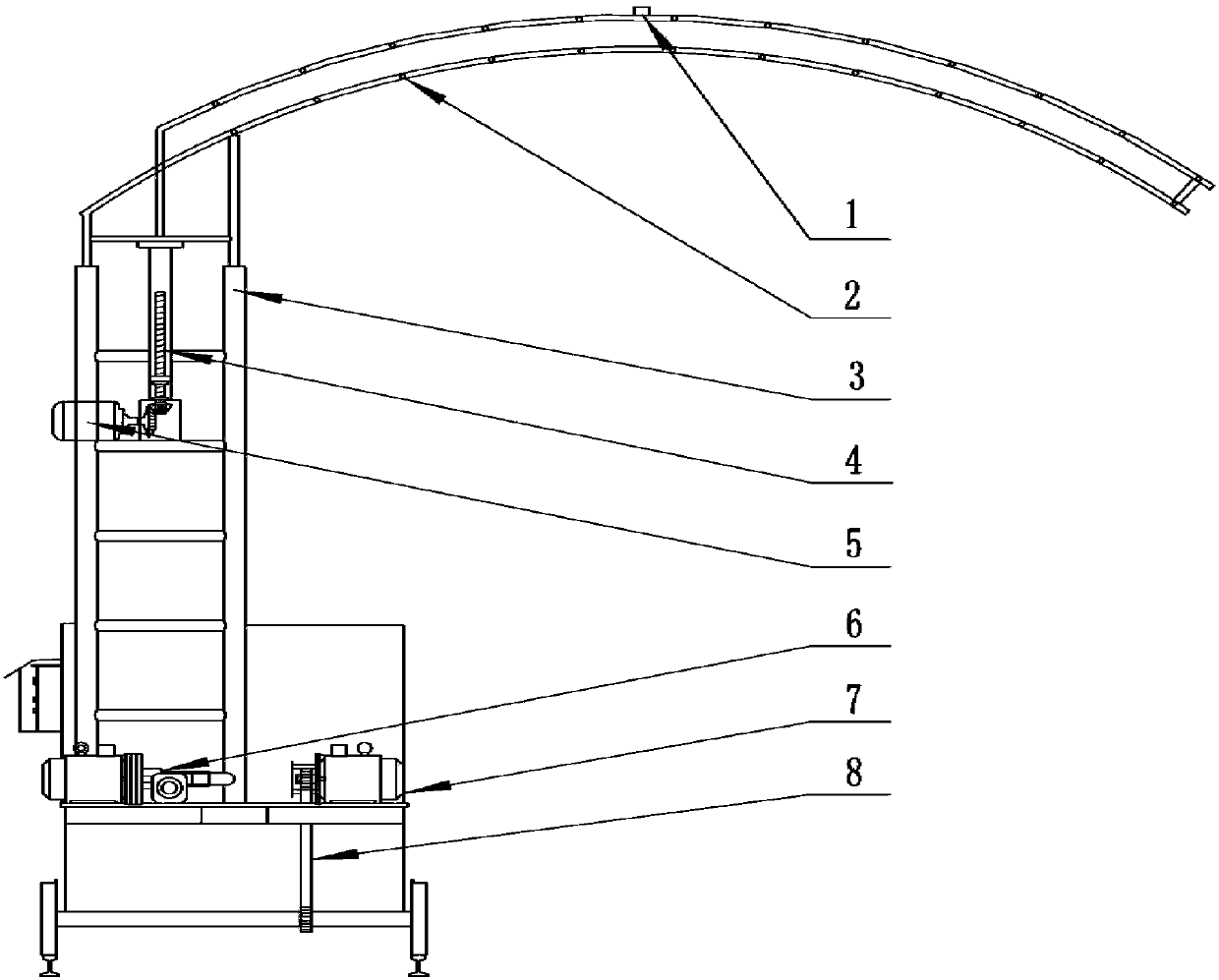

[0013] Maintenance equipment such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, it includes distance sensor 1, spray assembly 2, bracket 3, lifting device 4, lifting motor 5, water pump 6, travel motor 7, chain drive 8, vehicle body 9, water tank 10, magnetic flap liquid level gauge 11, electrical control cabinet 12. The body 9 is composed of a base and two sets of wheels. The bracket 3, the water pump 6 and the water tank 10 are installed on the body 9; the spray assembly 2 and the lifting device 4 are installed on the support 3, and the spray assembly 2 is connected by three water pipes through a tripod. The circular arc part of the end surface of the water pipe is evenly covered with the atomizing nozzle; the electrical control cabinet 12 is equipped with PLC, DTU, EM235 and other related electrical components, the output end of the magnetic flap level gauge 11 is connected to the input end of the EM235, and the output end of the PLC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com