Device and method capable of detecting stripes of optical glass prefabricated member

A glass preform and optical glass technology, which is used in measuring devices, material analysis by optical means, scientific instruments, etc., can solve the problems of inability to detect aspheric pressed preforms, and achieves small occupied space, convenient operation and inspection. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

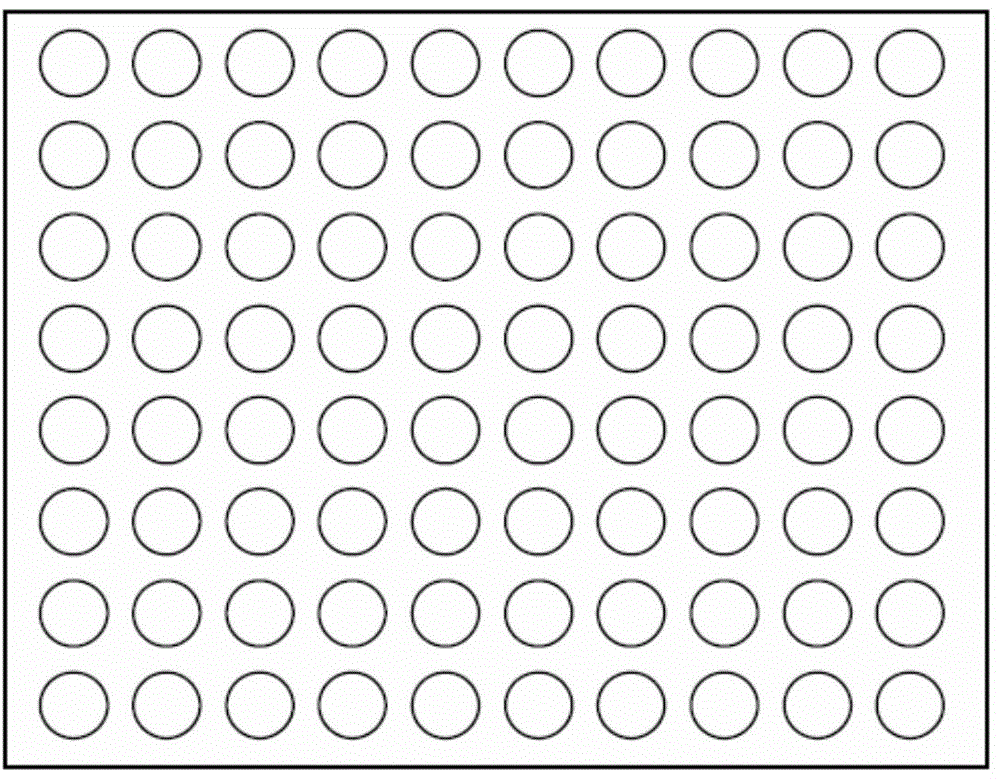

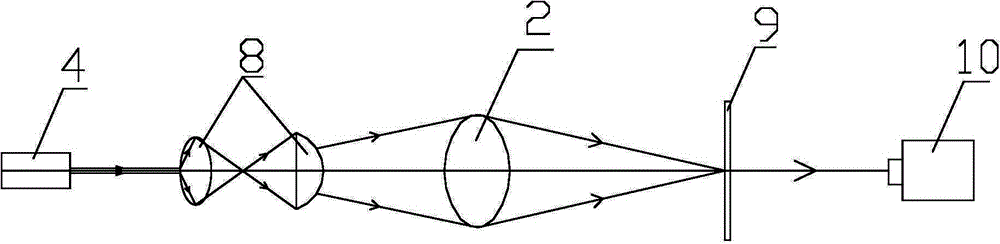

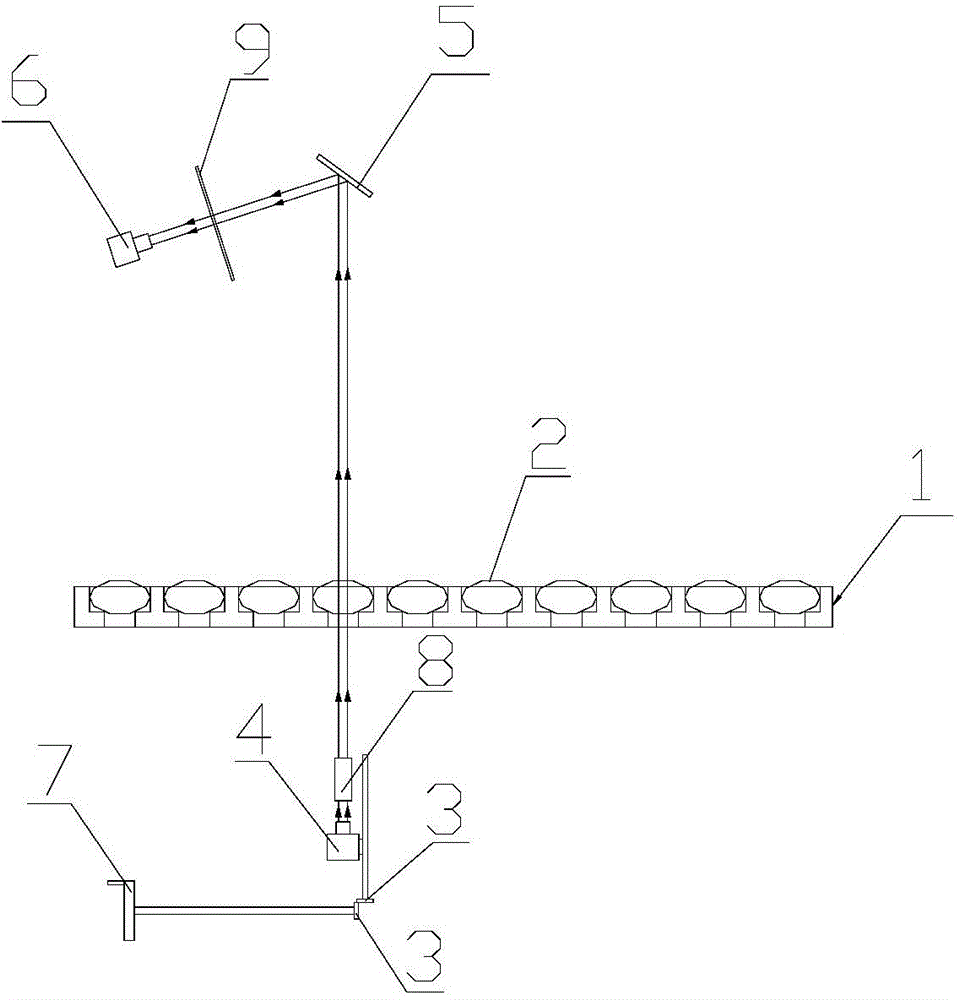

[0026] Since the laser has the advantages of small beam divergence angle and good coherence, the laser is used as the light source to make the beam pass through the ellipsoidal aspheric preform to form an interference image. If there are fringes inside the preform, a fringe interference image will be formed at the focal point .

[0027] Considering the sensitive wavelength band of human eyes, the present invention preferably adopts a laser with a wavelength of 532nm, a power of 10mw, and a light exit aperture of 2mm.

[0028] Since the laser output aperture is 2mm, the diameter of the ellipsoidal aspheric preform is generally Φ5-15mm. If laser irradiation is used directly, the beam cannot completely cover the entire preform, and the fringes on the edge of the preform are difficult to observe. However, if the clear aperture of the laser is increased, since the laser beam hardly diverges, a long distance must be added between the laser light source and the preform, which does n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com