Insulator hydrophobic surface local salt density measuring device and measuring method

A measuring device and insulator technology, applied in the direction of material resistance, etc., can solve the problem of the inability to continuously measure the accumulation and change of pollution on the insulating surface, the inability to complete the measurement of the equivalent salt-coated density of the insulating surface, and reduce the measurement steps of the equivalent salt-coated density, etc. problems, achieve stable and reliable measurement results, convenient and fast measurement, and improve stability and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

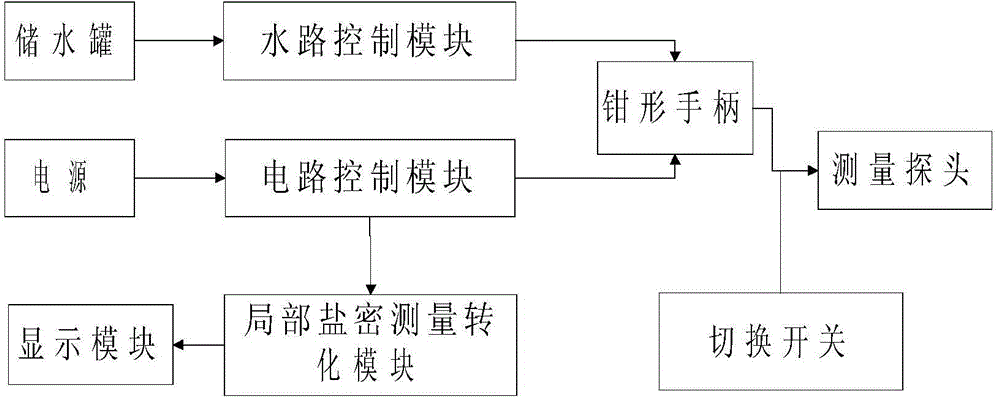

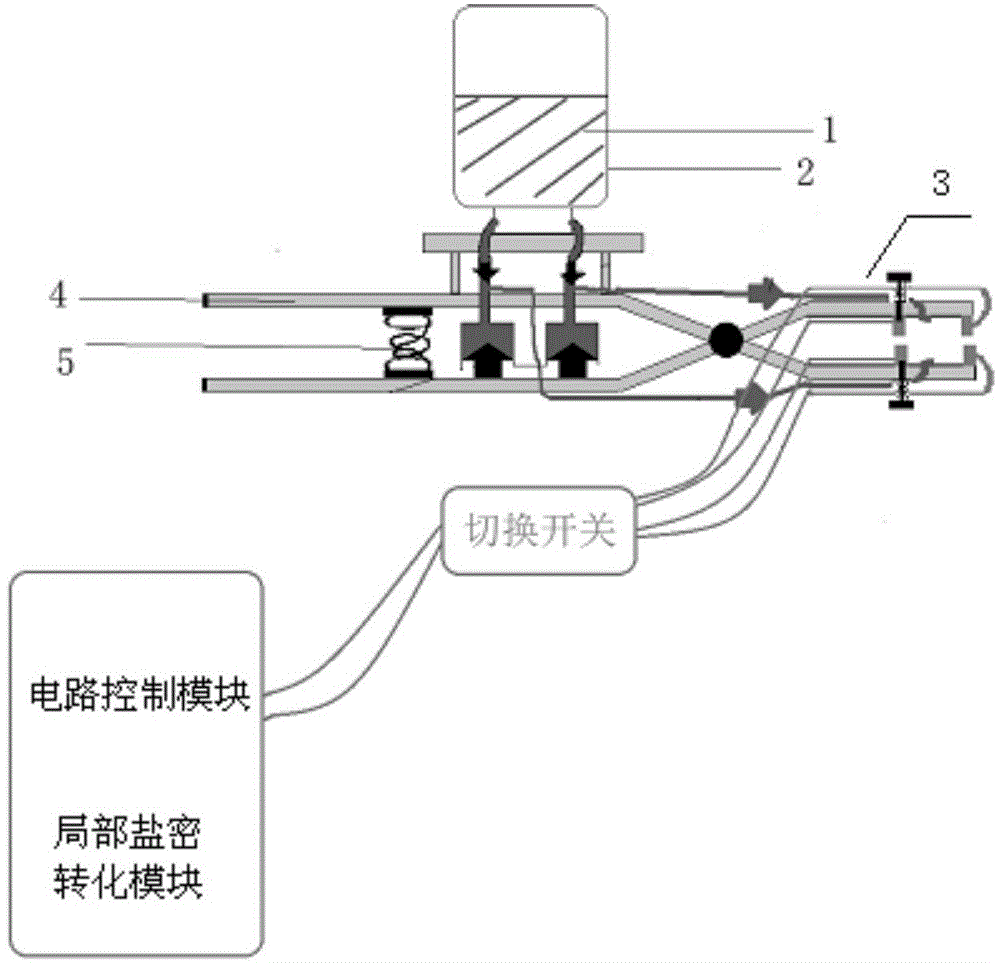

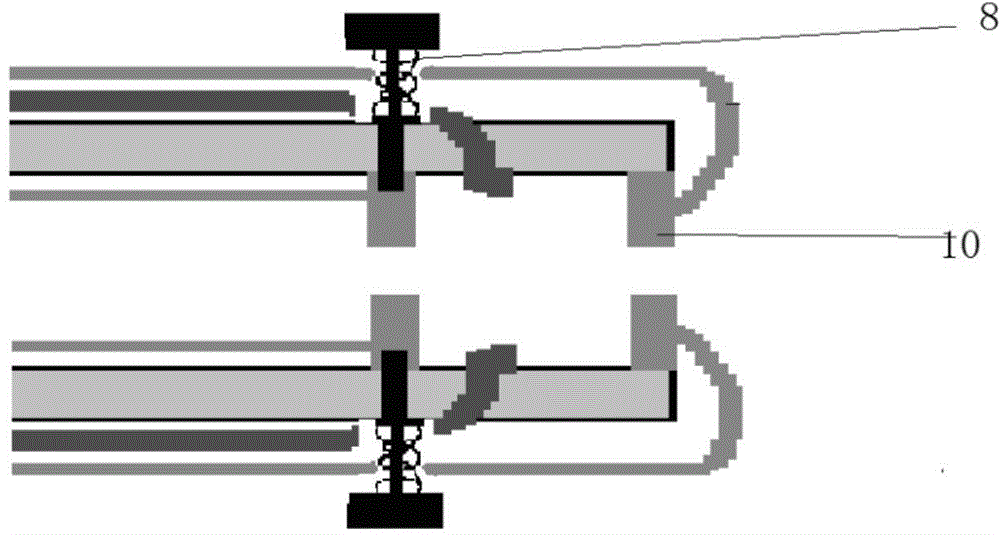

[0027] combine figure 1 , figure 2 , a local salt density measuring device on the hydrophobic surface of an insulator of the present invention, comprising: a water storage tank 2 for storing deionized water 1, a measuring probe 3, a water channel control module and a circuit control module for controlling the flow of deionized water , switch, local salt density conversion module, clamp device and DC power supply;

[0028] The water storage tank is connected to the measuring probe through the waterway control module, and the deionized water is delivered to the measuring probe, and the circuit control module is connected to the measuring probe to obtain the resistance value of the dirty liquid on the measuring probe;

[0029] The changeover switch is connected with the measuring probe, and is used for switching and measuring the resistance value of the dirt liquid on the upper and lower surfaces of the insulator;

[0030] The local salt density conversion module is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com