Thick fermented milk, its raw material composition and preparation method

A technology of raw material composition and fermented milk, which is applied in the field of its raw material composition and preparation, thick fermented milk, can solve the problems of strong powdery feeling, whey-flavored fermentation delay, etc., and achieve improved product taste and good taste stability , the effect of optimizing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

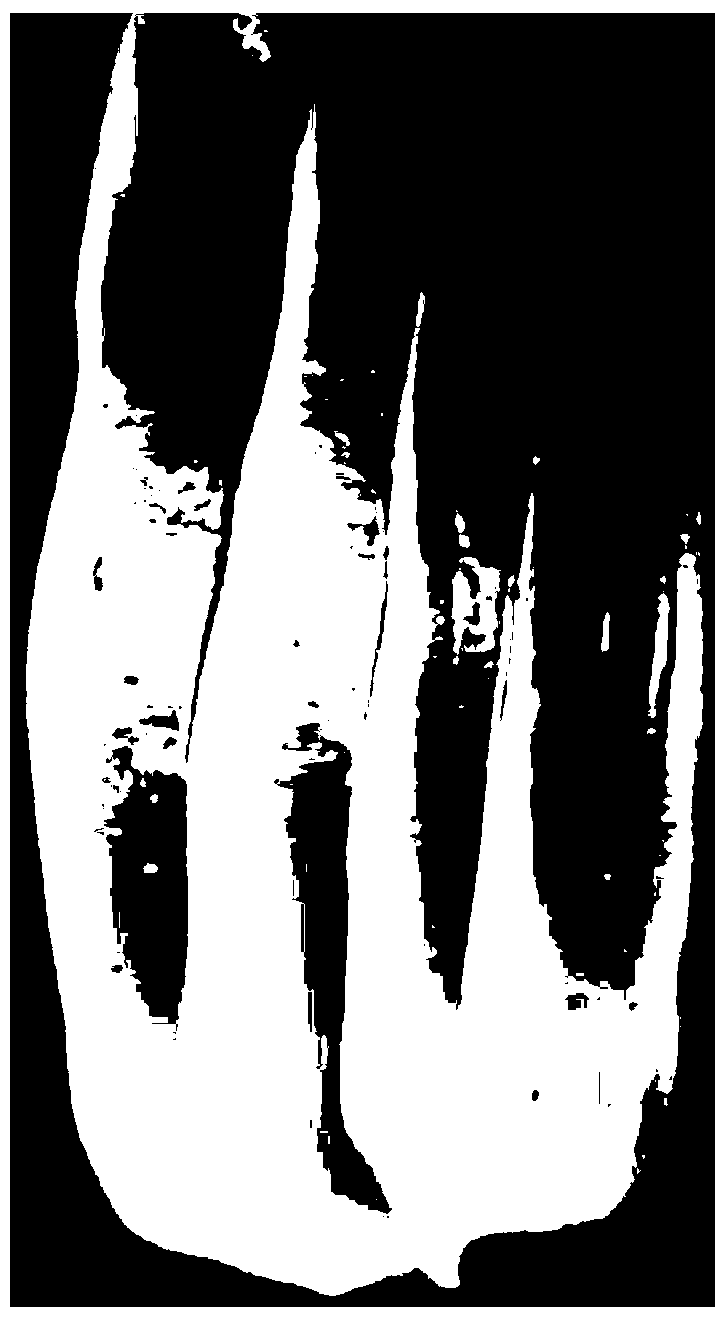

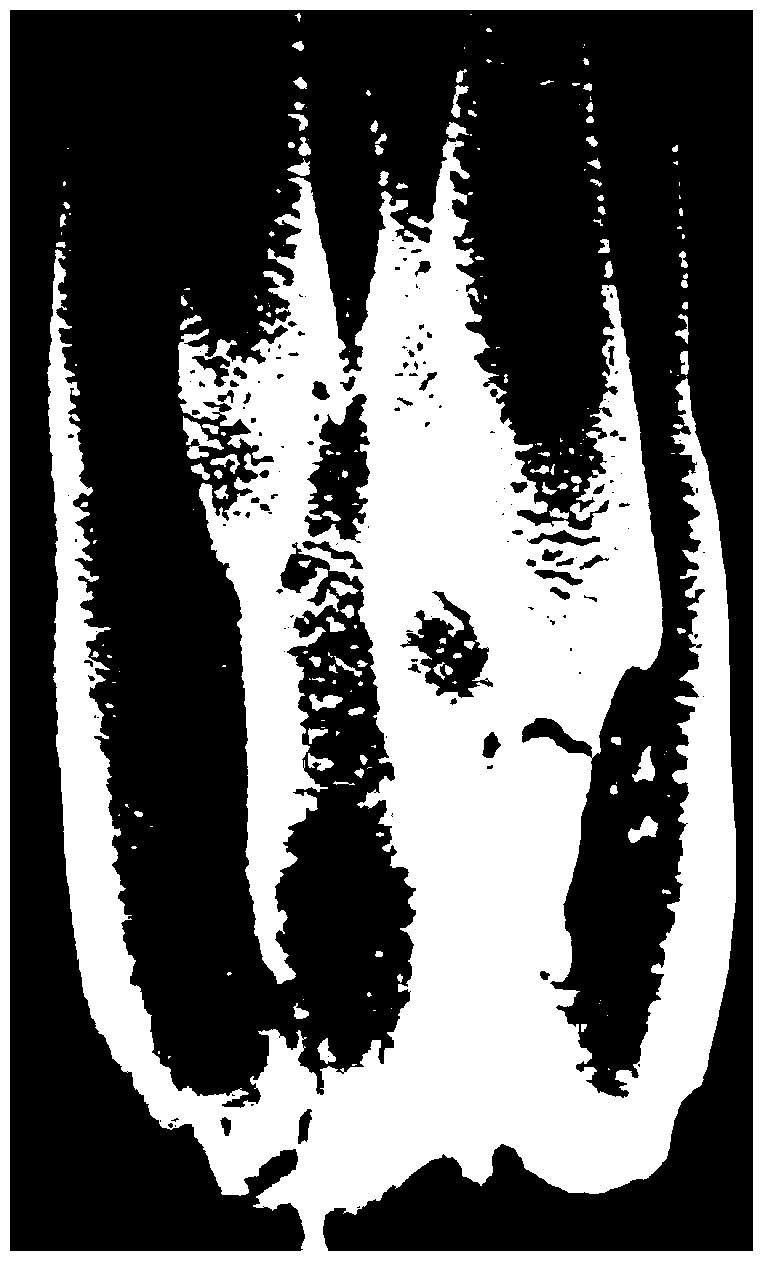

Image

Examples

Embodiment 1

[0051] 1. Raw material formula:

[0052] Whole milk 84.28%, sucrose 5.5%, sweetened condensed milk 4.5%, concentrated milk protein powder MPC854.1%, cream 1.6%, fermented bacteria So-Greek S20.02%.

[0053] The performance indicators of each raw material meet the requirements of conventional quality standards in this field.

[0054] Two, produce the product of the present embodiment according to following process method:

[0055] 1. Process flow:

[0056] Acceptance of raw milk→standardization of raw milk→ingredients→standstill→homogenization→sterilization→cooling→fermentation→turn over tank to cool→filling→refrigerate and ripen

[0057] 2. Process description:

[0058] 2.1 Acceptance of raw milk: acceptance according to the standard requirements of GB19301.

[0059] 2.2 Raw milk standardization: The standardized indicators should meet the requirements of the factory's internal control indicators. Whole-fat raw milk is standardized as raw milk, with fat ≥ 3.1%, protein ≥ ...

Embodiment 2

[0071] 1. Raw material formula:

[0072] Skimmed milk 86.42%, sugarcane concentrated juice 7.5%, evaporated milk 2.0%, concentrated milk protein powder MPC854.0%, cream 0.05%, fermented bacteria So-Greek S20.03%.

[0073] The performance indicators of each raw material meet the requirements of conventional quality standards in this field.

[0074] Two, produce the product of the present embodiment according to following process method:

[0075] 1. Process flow:

[0076] Acceptance of raw milk→standardization of raw milk→ingredients→standstill→homogenization→sterilization→cooling→fermentation→turn over tank to cool→filling→refrigerate and ripen

[0077] 2. Process description:

[0078] 2.1 Acceptance of raw milk: acceptance according to the standard requirements of GB19301.

[0079] 2.2 Raw milk standardization: The standardized indicators should meet the requirements of the factory's internal control indicators. The standardized skimmed raw milk is raw milk, its fat ≤ 0.5...

Embodiment 1

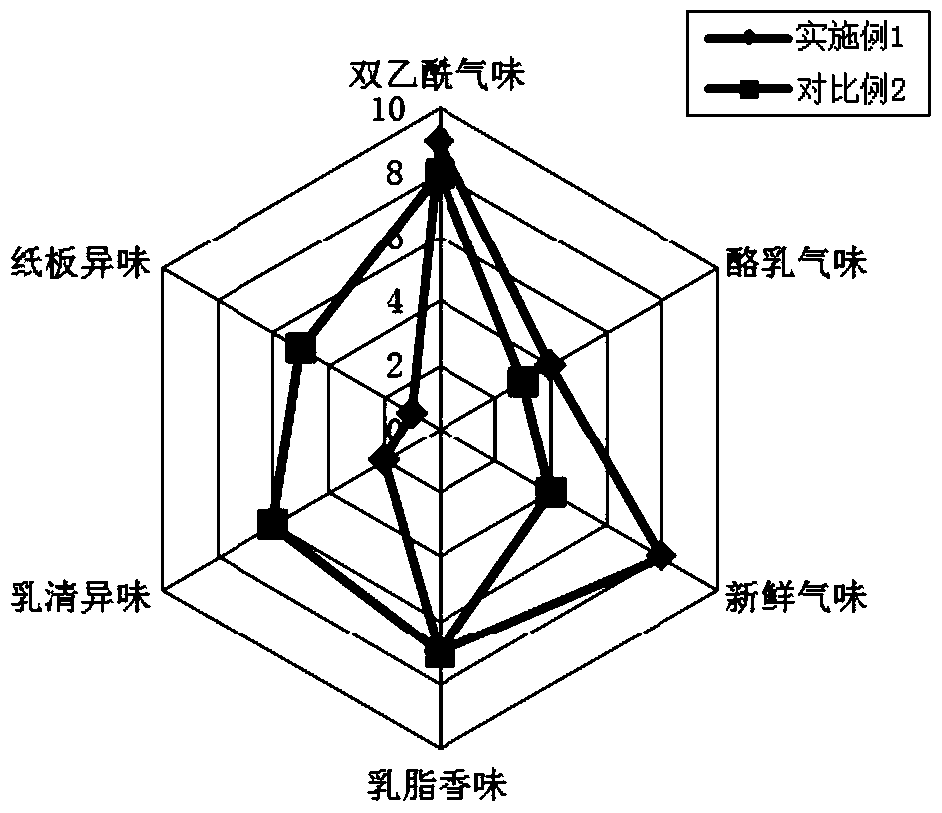

[0156] Sensory evaluation experiments were performed on the products produced in Example 1 (adding concentrated milk protein powder MPC85) and comparative example 2 (adding concentrated milk protein powder 470 and concentrated milk protein powder 4761).

[0157] The sensory evaluation items were: diacetyl odor, buttermilk odor, fresh odor, creamy aroma, whey odor, and cardboard odor.

[0158] A total of 102 people participated in the sensory evaluation experiment, and sensory evaluation was performed on the fermented milk products obtained in Example 1 and Comparative Example 2 respectively. The scoring range of each sensory evaluation item is from 1 to 10 points, and the scores are scored according to the strength of the specific sensory indicators. For the results of the sensory evaluation test, see image 3 .

[0159] from image 3 Analysis shows that Example 1 of the present invention has better diacetyl odor and buttermilk odor than Comparative Example 2, and these two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com