Preparation method of flavone-rich all-tartary buckwheat high-fiber puffed crisp chips

A technology of puffed crisps and tartary buckwheat, which is applied in the field of preparation of whole tartary buckwheat high-fiber puffed crisps, can solve problems such as rough taste, no products, lack of whole tartary buckwheat instant food, etc., to solve rough taste and increase nutrition value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

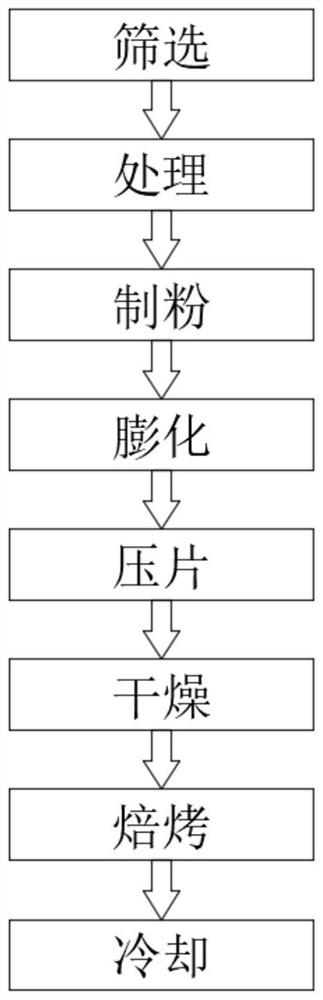

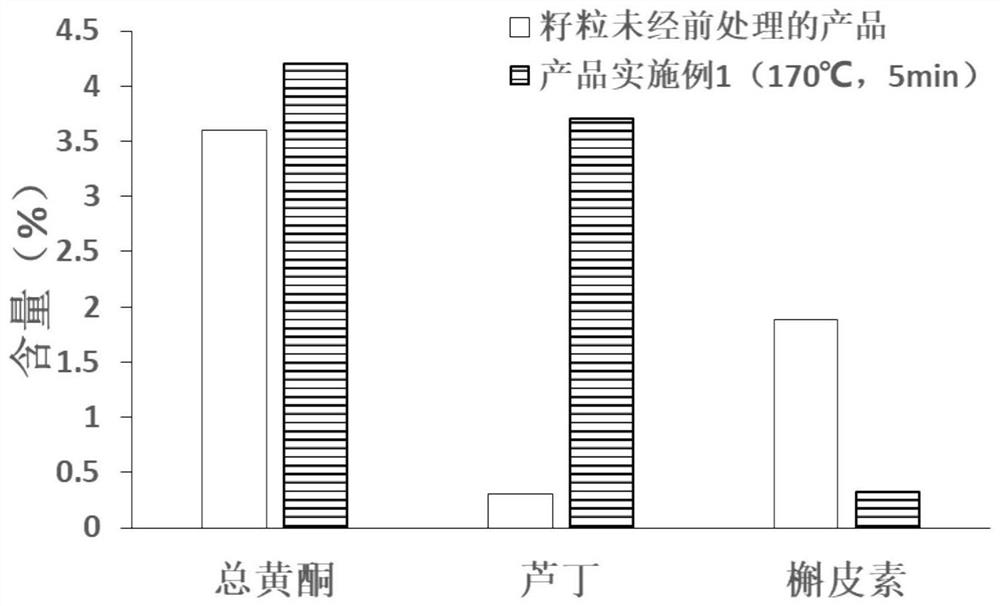

[0027] refer to Figure 1-3 , a preparation method of flavonoid-rich whole tartary buckwheat high-fiber puffed chips, comprising the following steps:

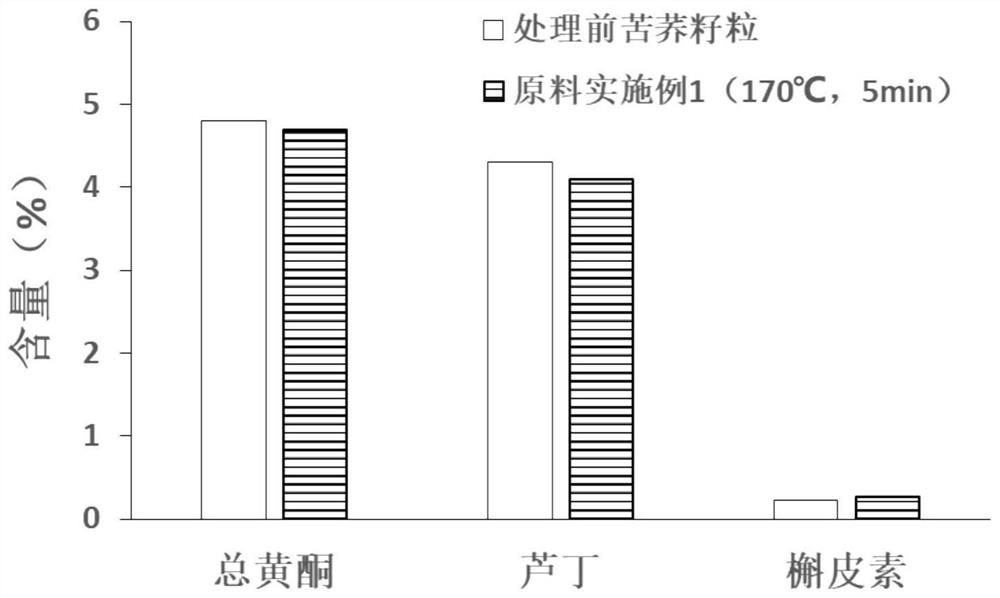

[0028] Step 1: Select tartary buckwheat varieties with a total flavonoid content of more than 4%, use superheated steam technology to treat whole tartary buckwheat grains, control the temperature to 170 ° C, and treat the time for 5 minutes, so that the content of rutin in the whole tartary buckwheat grains after treatment is reduced. less than 10%;

[0029] Step 2: The tartary buckwheat whole powder is obtained by crushing with two rollers, and the flow rate of the grinding is 120kg / min.

[0030] Step 3: Using twin-screw extrusion technology, the temperature of the three-stage cavity is 60-130°C, 130-160°C and 160-170°C, the rotation speed is 280rpm / min, the online water addition amount is 18%, and the whole tartary buckwheat is added. The powder is extruded and puffed to obtain a fluffy and porous texture with uniform pores...

Embodiment 2

[0041] refer to Figure 4 , a preparation method of flavonoid-rich whole tartary buckwheat high-fiber puffed chips, comprising the following steps:

[0042] Step 1: Select tartary buckwheat varieties with a total flavonoid content of more than 4%, use superheated steam technology to treat whole tartary buckwheat grains, control the temperature to 170 ° C, and treat the time for 5 minutes, so that the content of rutin in the whole tartary buckwheat grains after treatment is reduced. less than 10%;

[0043] Step 2: adopt airflow ultrafine pulverization, control the pulverization frequency to be 50hz, and the time to be 30 minutes, and control the average particle size of the whole tartary buckwheat powder to be below 50μm;

[0044] Step 3: Using twin-screw extrusion technology, the temperature of the three-stage cavity is 60-130°C, 130-160°C and 160-170°C, the rotation speed is 280rpm / min, the online water addition amount is 18%, and the whole tartary buckwheat is added. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com