Porphyra refreshing beverage and preparation method thereof

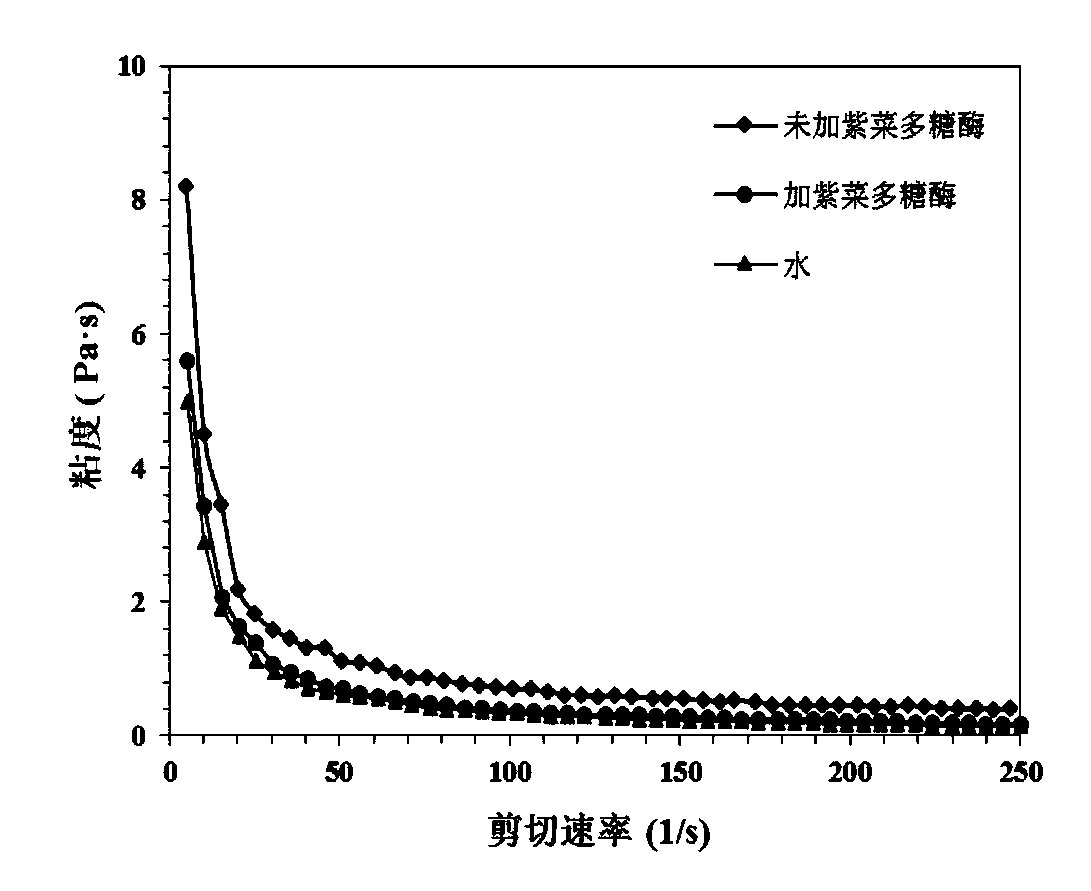

A technology of refreshing drinks and seaweed, which is applied in the field of food engineering and can solve the problems of high solution viscosity, unfavorable clarification, filtration, and low recovery rate of seaweed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

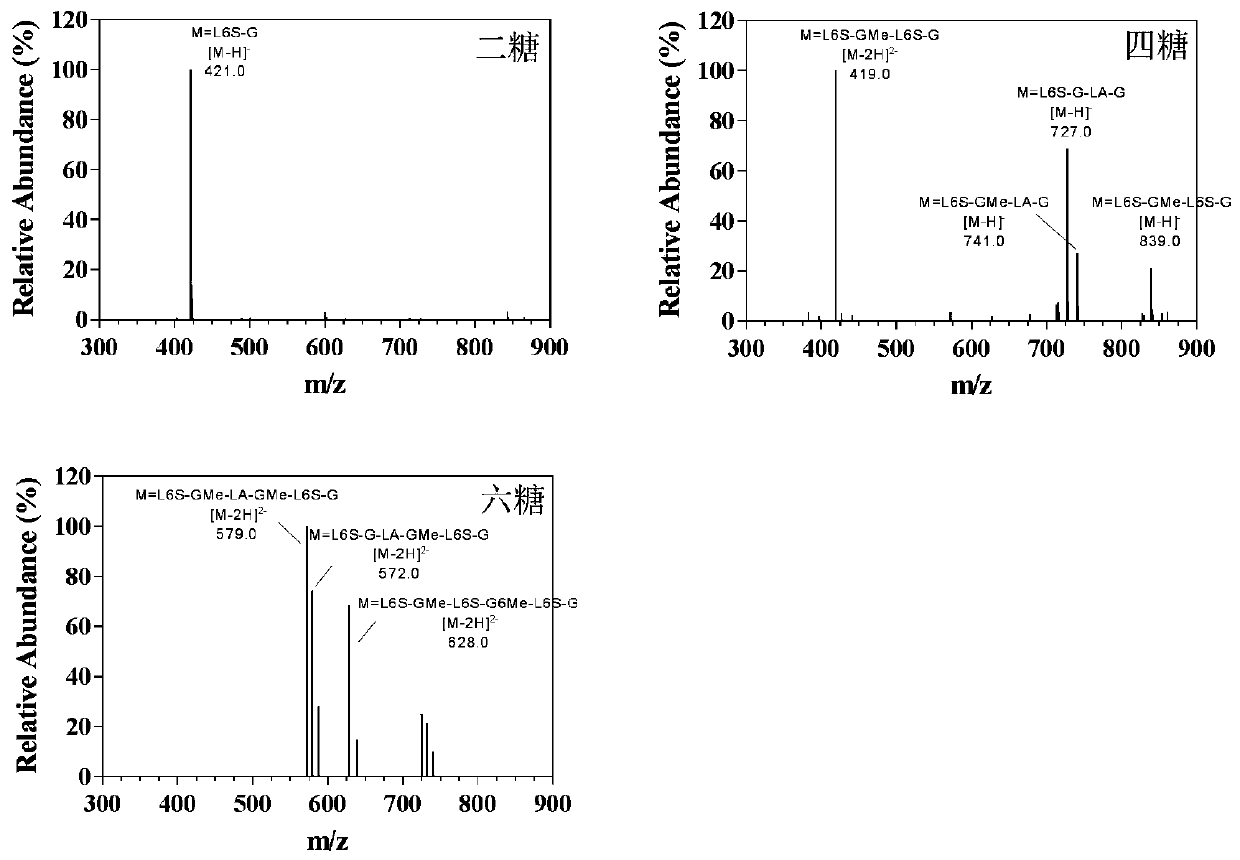

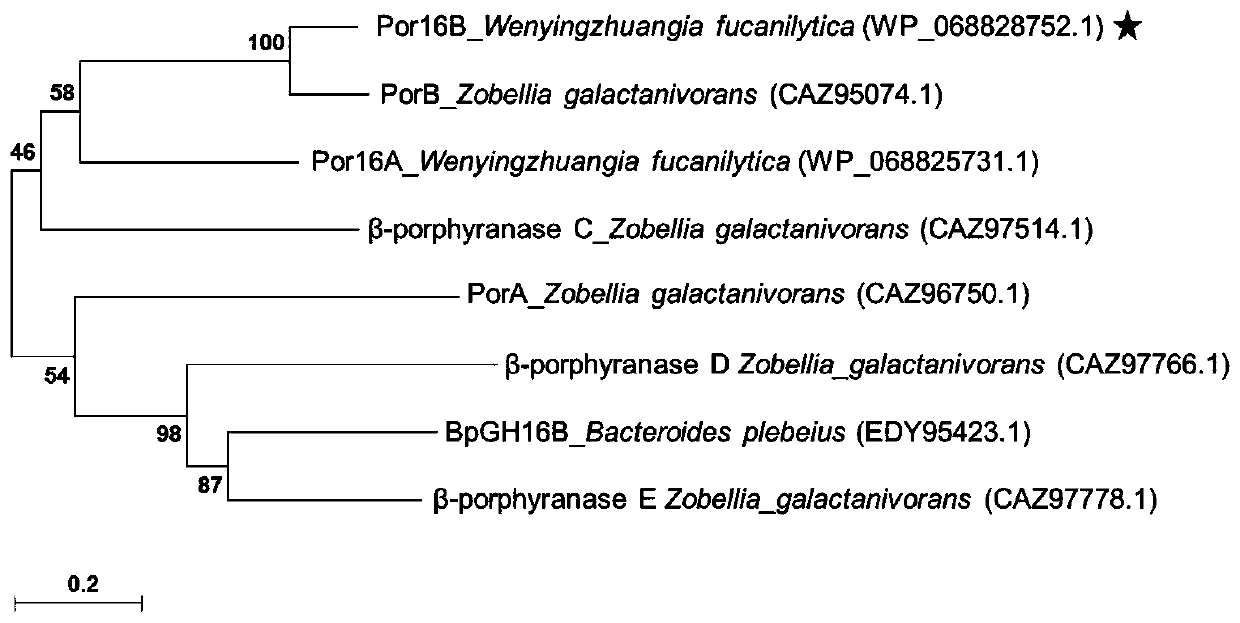

[0033] Embodiment 1: Laver polysaccharide enzyme Por16B_Wf is fermented and prepared in Pichia pastoris

[0034] Cultivation of Wenyingzhuangia fucanilytica CZ1127 in 2216E Medium T Until the end of the logarithmic phase, the whole genome DNA was extracted, and the upstream and downstream primers (5'-GACACGGATCCAAAGACAAAGTAGCAGTAAATGATACTACA; 5'-GACACCTCGAGCTATTGATATACTCTTACATAATCTATTTC) were designed according to the target gene, and PCR was carried out using the whole genome as a template. The PCR reaction conditions were: 95°C for 3min, 95°C for 20s, 42°C for 22 s, 72°C for 60 s, 22 cycles, and finally 72°C for 5 min to obtain the por16B_Wf gene fragment of Porphyra polysaccharase, use EcoRI and NotI double enzymes to digest the target gene and pPIC9k plasmid, connect to form a recombinant plasmid, and digest with Sal I After that, add it to Pichia pastoris GS115 competent cells to form recombinant cells; resuspend the cells with 10mM pH8.0 N,N-bishydroxyethylglycine after ...

Embodiment 2

[0037] Embodiment 2: the preparation of laver refreshing drink

[0038] Grind the dried seaweed for later use. According to the solid-liquid ratio of 1:25 (w / v), water was added to laver powder to soak and rehydrate for 40 minutes, and the pH was adjusted to 6.5. Neutral protease was added according to the enzyme amount of 10500 U / g laver, and enzymolysis was carried out at 45°C for 8 hours to obtain high Viscosity of laver enzymatic hydrolysis solution. Add laver polysaccharide enzyme according to the enzyme amount of 0.05-2U / g, enzymolyze at 35°C for 0.5-4h, inactivate the enzyme at 100°C, centrifuge at 4000rpm for 15min or filter with diatomaceous earth, the obtained supernatant is laver enzymatic hydrolysis solution.

[0039] Adjust the content of laver enzymatic hydrolyzate to 40%, add sucralose to 0.014%, and add citric acid to 0.1%, heat it at 80°C for 7 minutes after filling, seal the can, pasteurize it for 8 minutes, and store it at low temperature to obtain laver R...

Embodiment 3

[0040] Embodiment 3: the recovery rate determination of laver

[0041] According to the quality of laver before and after enzymatic hydrolysis, the extraction efficiency of laver content by water and enzymatic hydrolysis process is the recovery rate of laver. The laver enzymatic hydrolyzate was centrifuged and the precipitate obtained was separated, weighed, and the recovery rate X of laver was calculated. X=(mass of dry laver powder-mass of precipitate after freeze-drying) / mass of dry laver powder×100%.

[0042] Table 1 recovery rate of laver

[0043] Group 1_Neutral protease group Group 2_Neutral protease+Porphyra polysaccharase group Recovery rate of laver 66% 79%

[0044] After adding Porphyra polysaccharase, Porphyra recovery increased by 13%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com