Functional composite soybean milk beverage and preparation method thereof

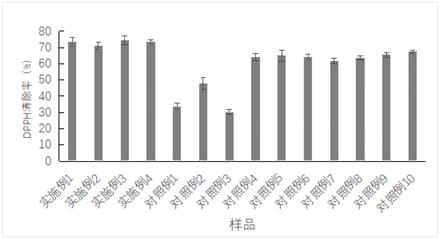

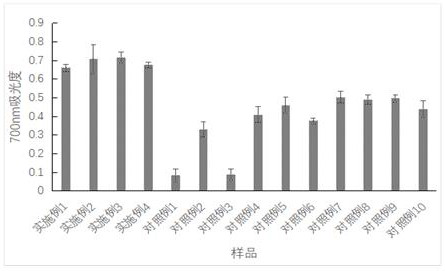

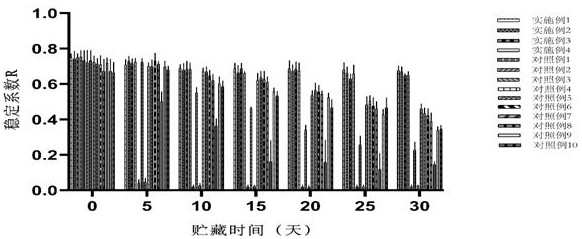

A functional and beverage technology, applied in dairy products, milk substitutes, food science and other directions, can solve the problems of insufficient product flavor and backward technology, and achieve improved DPPH clearance rate and reducing power, high sensory acceptance, and better flavor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation steps are as follows:

[0032] Select 200g of chickpeas, 300g of snow peas and 160g of lentils, and then soak them repeatedly with flowing water, add 7000g of water, soak overnight, break and beat at 20000rpm / min for 15min to obtain a mixed slurry, and filter with a 200-mesh filter cloth Finally, add 500 g of the mixture of isomalt and D-mannitol to the filtrate, stir at 100 rpm / min for 15 min for uniform mixing. The above mixed slurry was treated at 100°C for 10 minutes, and after cooling to room temperature, 3g of food-grade Lactobacillus casei, Lactobacillus acidophilus, Lactobacillus rhamnosus and Lactobacillus reuteri were added to make the number of lactic acid bacteria in the mixed slurry reach 8.0x10 9 CFU / mL, stirred at 150rpm / min for 120h at 8°C. Ultrasonic treatment is performed on the mixed slurry every 12 hours in the ultra-clean bench. The frequency of the ultrasonic treatment equipment is 28kHz, the ultrasonic intensity is 40W / L, the ultr...

Embodiment 2

[0035] The preparation steps are as follows:

[0036] Select 300g of chickpeas, 450g of snow peas and 330g of lentils, then soak them repeatedly with flowing water, add 9000g of water, soak overnight, break and beat at 30000rpm / min for 19min to obtain a mixed slurry, and filter with a 400-mesh filter cloth Finally, 600 g of the mixture of isomalt and D-mannitol was added to the filtrate, and stirred at 200 rpm / min for 20 min for uniform mixing. The above mixed slurry was treated at 100°C for 15 minutes, and after cooling to room temperature, 9g of food-grade Lactobacillus casei, Lactobacillus acidophilus, Lactobacillus rhamnosus and Lactobacillus reuteri were added to make the number of lactic acid bacteria in the mixed slurry reach 10.0x10 9 CFU / mL, stirred at 300rpm / min for 168h at 12°C. Ultrasonic treatment is performed on the mixed slurry every 12 hours in the ultra-clean bench. The frequency of the ultrasonic treatment equipment is 68kHz, the ultrasonic intensity is 200W...

Embodiment 3

[0039] The preparation steps are as follows:

[0040] Select 250g of chickpeas, 370g of snow peas and 240g of lentils, then soak them repeatedly with flowing water, add 8000g of water, soak overnight, break and beat at 22000rpm / min for 16min to obtain a mixed slurry, and filter with a 300-mesh filter cloth Finally, 560 g of the mixture of isomalt and D-mannitol was added to the filtrate, and stirred at 170 rpm / min for 17 min for uniform mixing. The above mixed slurry was treated at 100°C for 14 minutes, and after cooling to room temperature, 6g of food-grade Lactobacillus casei, Lactobacillus acidophilus, Lactobacillus rhamnosus and Lactobacillus reuteri were added to make the number of lactic acid bacteria in the mixed slurry reach 9.0x10 9 CFU / mL, stirred at 260rpm / min for 156h at 10°C. Ultrasonic treatment is performed on the mixed slurry every 12 hours in the ultra-clean bench. The frequency of the ultrasonic treatment equipment is 40kHz, the ultrasonic intensity is 100W / L,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com