Method for reducing heavy metal cadmium in rice through fermentation technology

A fermentation process and a heavy metal technology are applied in the field of purifying and treating rice with excess cadmium, which can solve the problems of high safety, low operating cost, and reduce the cadmium content in rice, and achieve the effects of simple operation and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

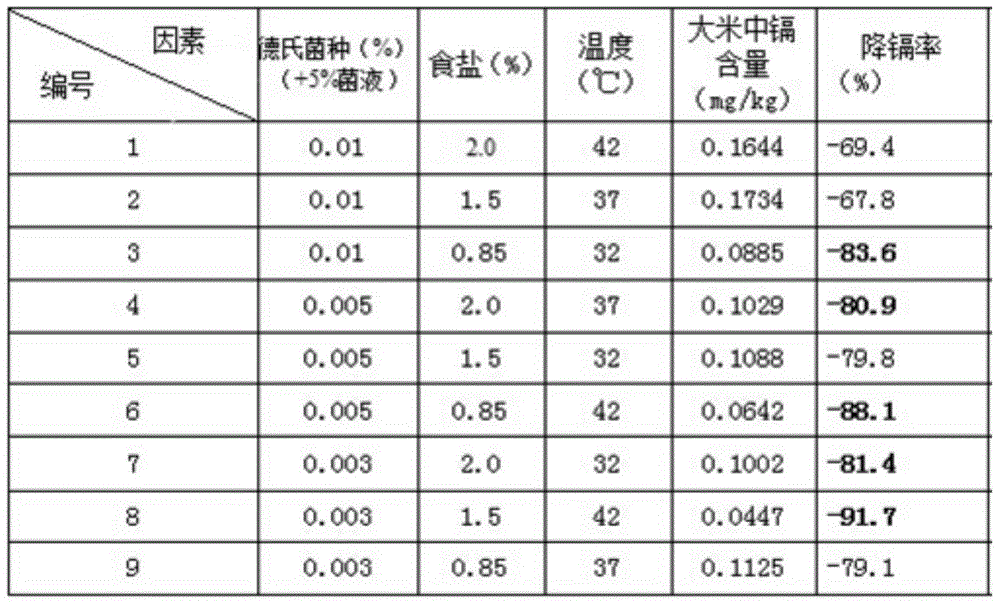

Method used

Image

Examples

Embodiment 1

[0027] (1) Rice: Prepare 10kg of ordinary processed rice (cadmium ≥ 0.2mg / kg), 11kg of water, 165g of salt, and reserve;

[0028] (2) Prepare mixed strains: Take 650g of fermented liquid fermented naturally for 24 hours during the production of fermented rice noodles, in which the ratio of Lactobacillus fermentum, Lactobacillus salivarius, Lactobacillus plantarum and Lactobacillus reuteri is 30:9:5 : 4, the total bacterial count of the mixed bacterial solution is about 102cfu / g, Lactobacillus delbrueckii 0.65g (Streptococcus thermophilus: Lactobacillus bulgaricus=1:1), set aside;

[0029] (3) Heating: Heat the water to about 42°C (ambient temperature 30°C), add the salt prepared in step (2), stir evenly, then add bacteria, stir evenly, and set aside;

[0030] (4) Soaking: directly add the rice in step (1) to the warm water prepared in step (3), fully contact the rice with water, rice: water = 1: 1.1;

[0031] (5) Fermentation: Incubate the mixture of rice and bacteria in step...

Embodiment 2

[0038] (1) Rice: Prepare 10kg of ordinary processed rice (cadmium ≥ 0.2mg / kg), 10kg of water, 260g of salt, and reserve;

[0039] (2) Prepare mixed strains: Take 88g of fermented liquid fermented naturally for 24 hours during the production of fermented rice noodles, in which the ratio of Lactobacillus fermentum, Lactobacillus salivarius, Lactobacillus plantarum and Lactobacillus reuteri is 30:9:5 : 4, the total bacterial count of the mixed bacterial solution is about 80cfu / g, 0.33g of Lactobacillus delbrueckii (Streptococcus thermophilus: Lactobacillus bulgaricus=1:1), set aside;

[0040] (3) Heating: Heat the water to about 40°C (ambient temperature 30°C), add the salt prepared in step (2), stir evenly, then add bacteria, stir evenly, and set aside;

[0041] (4) Soaking: directly add the rice in step (1) into the warm water prepared in step (3), fully contact the rice with water, rice: water = 1: 1.3;

[0042] (5) Fermentation: Incubate the mixture of rice and bacteria in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com