A semi-preparative chromatographic column fast filling device and its preparation method

A technology for semi-preparative chromatography and filling device, which is applied to the field of semi-preparative chromatography column rapid filling device and its preparation, can solve the problems of reducing test repeatability and product stability, uneven distribution of chromatography column, low efficiency, etc. Separation cycle, increase chromatographic processing capacity, and ensure the effect of test repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

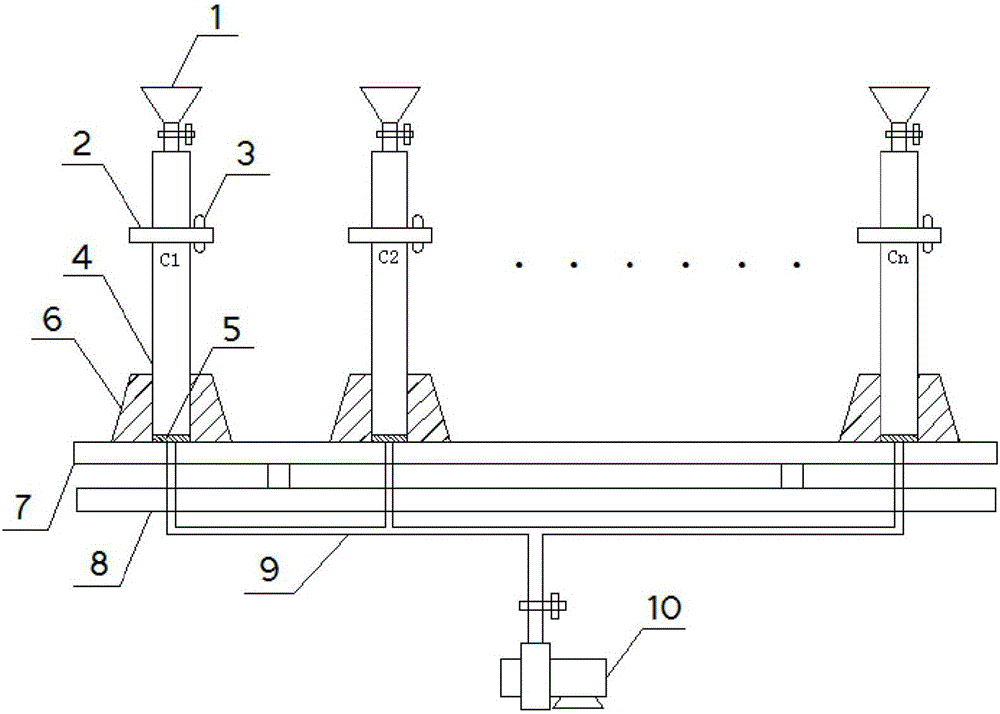

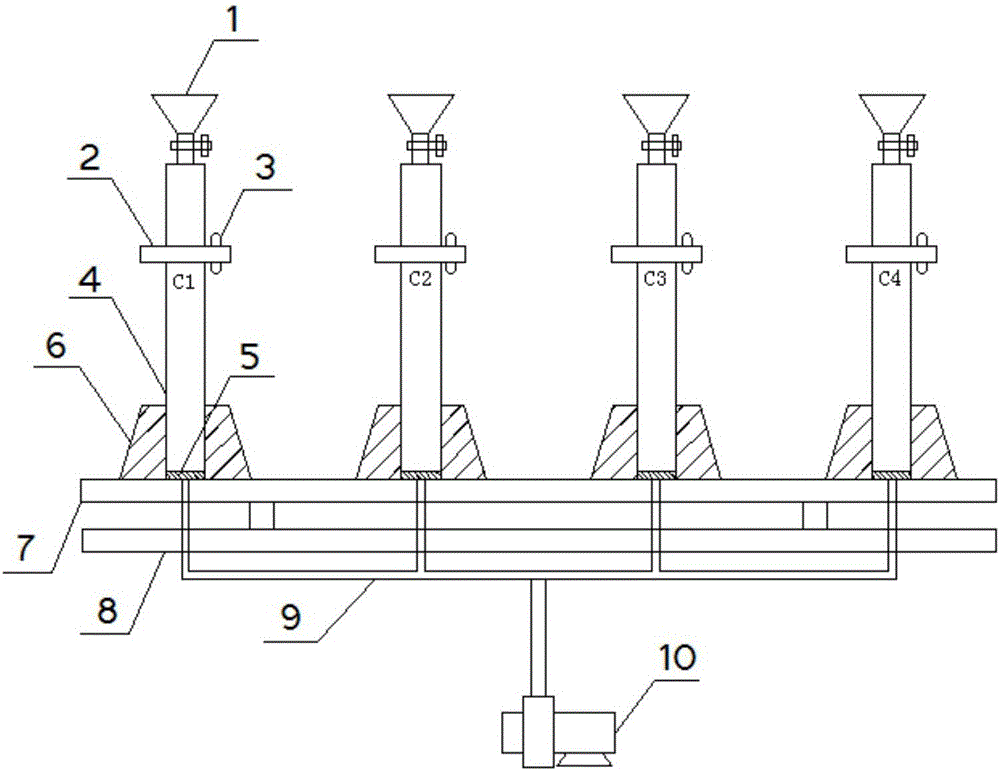

[0017] as attached figure 1 As shown, first open the valves of C1 to Cn feeder 1 in the semi-preparative chromatographic column unit one by one, close the valve of the feeder when it is full for the first time, continue to open the valve after oscillation and suction, and repeat until The bed no longer descends and the filling process is complete. The vibrator ring clamp 2 is made of metal with a rubber lining, and clamps the vibrator 3 in a vertical direction, and through the vibration of the vibrator 3, the vertical vibration of the packing is realized. The quartz gasket 5 is located at the bottom of the chromatographic column 4 to prevent fillers from entering the suction hose 9 along with the eluent. The chromatographic column clamping block 6 is made of rubber, and is fixed on the horizontal oscillating platform 7 to keep the chromatographic column 4 vertical. The horizontal oscillating table 7 is located on the bottom plate 8 to realize vibration in the X and Y directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com