Bilateral laser-InFocus electric arc composite welding method for T-type joint

An -infocus and hybrid welding technology, applied in the field of laser-InFocus arc hybrid welding on both sides of T-shaped joints, can solve the problems of high laser power requirements, high cost, and small arc penetration, and achieve high current force and energy density , Welding speed is fast, and the effect of reducing positioning variables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

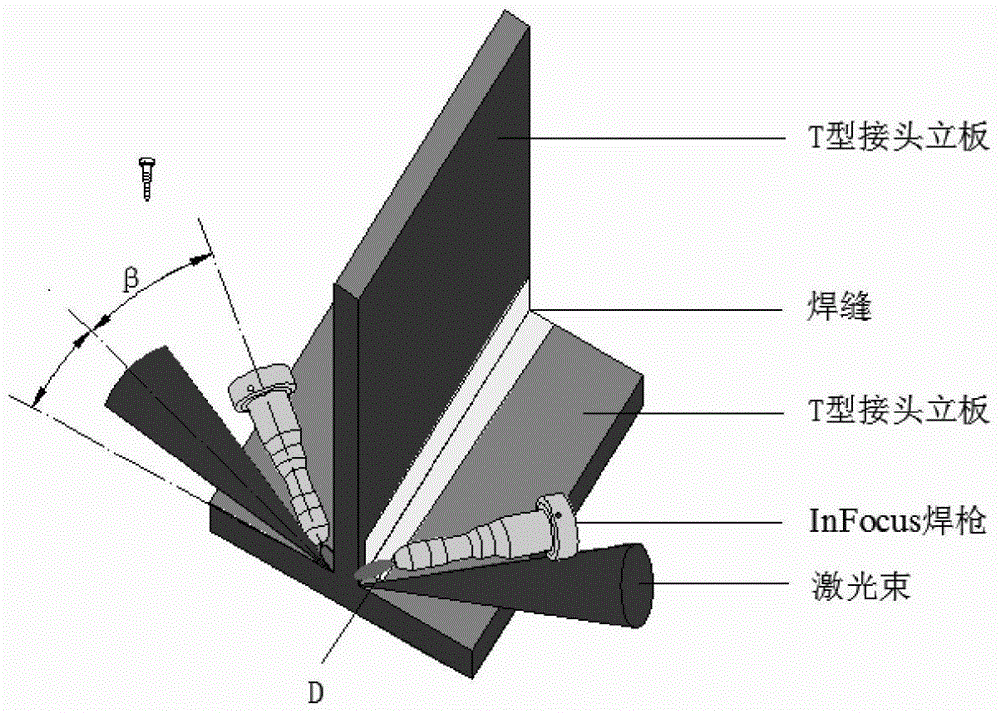

[0023] Specific embodiment one: A kind of T-joint bilateral laser-InFocus electric arc hybrid welding method of this embodiment, it is carried out according to the following steps:

[0024] Step 1: Process the part of the workpiece to be welded into a groove or not. Before welding, grind the double-sided symmetrical welding groove and the surface within 30mm of the two sides, and then clean the groove and both sides of the groove with acetone. side surface;

[0025] Step 2: the workpiece is fixed on the fixture to be welded;

[0026] Step 3: Keep the angle between the laser beam and the arc and the longitudinal surface of the T-joint panel as α, α is 10°-45°, and the angle β between the laser beam and the arc is 30°-45°, adjust The distance between the cathode end point and the laser focal plane is 2-3mm, and the distance between the two heat sources is 1-2mm;

[0027] Step 4: Set the process parameters, the laser power on both sides is 1000W~3000W; the arc current on both s...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the laser beam is perpendicular to the normal direction of the transverse surface of the T-joint panel, and the welding is carried out along the normal direction of the transverse surface of the T-joint panel. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the double-sided laser-InFocus arc hybrid welding method of the T-shaped joint refers to using two laser beams and two InFocus welding torches on both sides of the T-shaped joint respectively on both sides of the joint. Side forming method of laser-InFocus composite and simultaneous welding. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com