Automatic chamfering, cutting-off and deburring device for steel pipe

A deburring and automatic technology, applied in the field of machining, can solve the problems of increased tool production and purchase costs, increased production costs of enterprises, and increased chamfering processes, and achieves the effect of simple structure, reduced production costs of enterprises, and improved machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

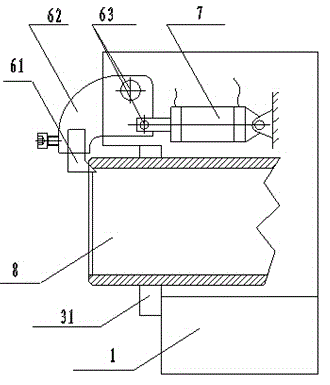

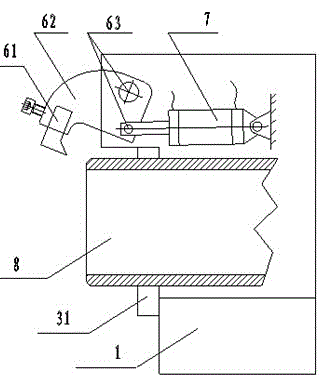

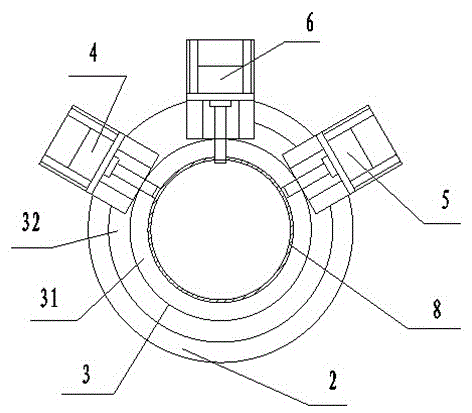

[0014] Such as figure 1 , figure 2 and image 3 As shown, a steel pipe automatic chamfering, cutting and deburring device of the present invention includes a machine tool 1, a support 2, a positioning mechanism 3, an outer corner chamfering mechanism 4, a cutting mechanism 5, an inner corner chamfering mechanism 6, and a hydraulic cylinder 7. The seat 2 is arranged on the machine tool 1, the positioning mechanism 3 includes a clamp 31 and an auxiliary clamp 32, the chamfering mechanism 4, the cutting mechanism 5 and the chamfering mechanism 6 are respectively arranged on the support 2, and the chamfering mechanism 6 It includes a tool 61, a tool holder 62 and a hinge shaft 63, the tool 61 is arranged on the tool holder 62, the tool holder 62 is respectively connected to the axial main shaft and the radial main shaft of the hydraulic cylinder 7 through the hinge shaft 63, and also includes An automatic control system, the automatic control system is electrically connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com