Pipe inner wall polishing method

A pipe and pipe wall technology, which is applied in the polishing field of the inner wall of the pipe, can solve the problems of polishing mechanism wear, easy to be eroded by the polishing fluid, and affect oil transmission, etc., and achieve the effect of maintaining stable rotation, increasing service life, and flexible installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

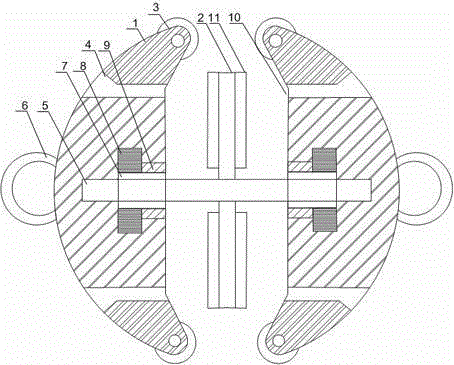

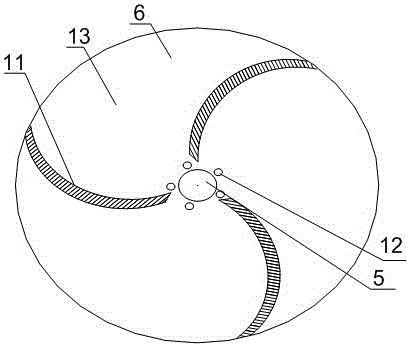

[0021] like figure 1 , 2 As shown, the present invention first injects the polishing liquid into the clamped and fixed petroleum elbow, and is connected with the lifting lug by a steel rope. Driven by the traction device, the polishing mechanism enters the elbow, and the polishing liquid flows from the polishing mechanism to the elbow. The gap between the inner walls of the elbow flows out quickly, and the polishing fluid acts on the pipe wall. After the high-speed movement of the abrasive particles, the corners or protrusions on the inner wall of the elbow are sheared and removed, and then polishing is achieved. The effect; the flowing grinding fluid drives the impeller to rotate freely, and the impeller can rotate and spray part of the grinding fluid onto the pipe wall, so as to assist in grinding the inner wall of the elbow. When the grinding fluid impacts the pipe wall, it will also fall off the pipe wall The iron filings are cleaned; the two opposite protection shells ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com