All-steel tread sizing material and preparing method thereof

A steel tire and surface rubber technology, applied in the chemical industry, can solve the problems of insufficient wear resistance of the tread formula, reduce heat generation of the rubber material, and general wear resistance, so as to improve wear resistance, ensure tear resistance, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

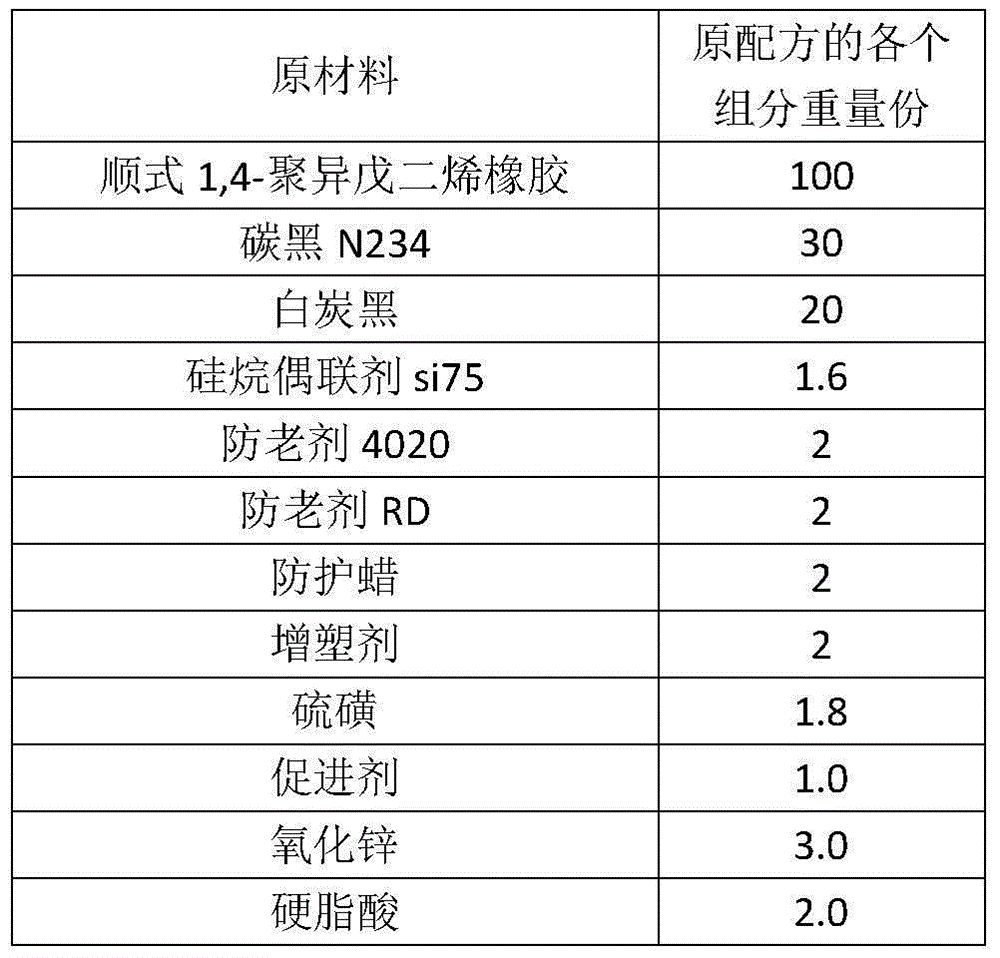

Method used

Image

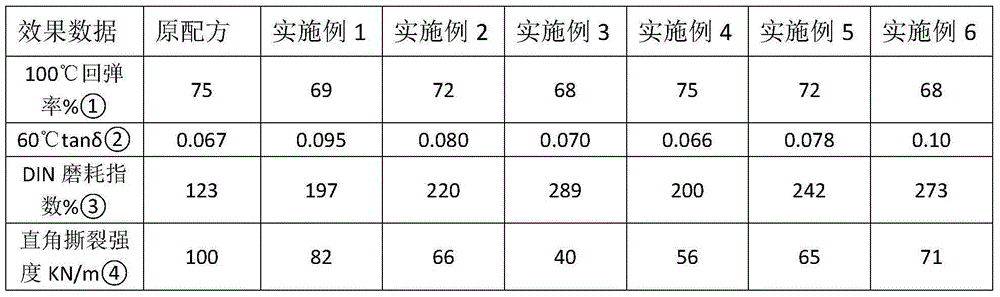

Examples

Embodiment 1

[0037] 85 parts of cis-1,4-polyisoprene rubber, 15 parts of neodymium-based high-cis-polybutadiene, 48 parts of carbon black V9H, 40202 parts of anti-aging agent, 2 parts of anti-aging agent RD, 2 parts of protective wax, 2 parts of plasticizer, 1.8 parts of sulfur, 1.0 part of accelerator, 3.0 parts of nano zinc oxide, 2.0 parts of stearic acid.

[0038] The preparation method of described all-steel tread compound is as follows:

[0039] Considering that the viscosity of the final mixing rubber can meet the extrusion process, the rubber material is divided into four stages of mixing.

[0040] Weigh each component according to the metering point;

[0041] One-stage mixing: Add cis-1,4-polyisoprene rubber, neodymium-based high-cis-polybutadiene rubber, V9H carbon black, anti-aging agent, protective wax, stearic acid, nano Zinc oxide, internal mixer speed 40-60rpm / min, pressure 0.4-0.55MPa, pressurize for 40-50s and then lift the mound, keep the pressure for 5-10s, lift for 20...

Embodiment 2

[0046] A kind of all-steel tread compound, in parts by weight, comprises the following components:

[0047] 80 parts of cis-1,4-polyisoprene rubber, 20 parts of neodymium-based high-cis-polybutadiene, 48 parts of carbon black V9H, 40202 parts of anti-aging agent, 2 parts of anti-aging agent RD, 2 parts of protective wax, 2 parts of plasticizer, 1.8 parts of sulfur, 1.0 part of accelerator, 3.0 parts of nano zinc oxide, 2.0 parts of stearic acid.

[0048] The preparation method of described all-steel tread compound is as follows:

[0049] Considering that the viscosity of the final mixing rubber can meet the extrusion process, the rubber material is divided into four stages of mixing.

[0050] Weigh each component according to the metering point;

[0051] One-stage mixing: Add cis-1,4-polyisoprene rubber, neodymium-based high-cis-polybutadiene rubber, V9H carbon black, anti-aging agent, protective wax, stearic acid, nano Zinc oxide, internal mixer speed 40-60rpm / min, pressure ...

Embodiment 3

[0056] A kind of all-steel tread compound, in parts by weight, comprises the following components:

[0057] 65 parts of cis-1,4-polyisoprene rubber, 35 parts of neodymium-based high-cis-polybutadiene, 48 parts of carbon black V9H, 402015 parts of anti-aging agent, 2 parts of anti-aging agent RD, 2 parts of protective wax, 2 parts of plasticizer, 1.8 parts of sulfur, 1.0 part of accelerator, 3.0 parts of nano zinc oxide, 2.0 parts of stearic acid.

[0058] The preparation method of described all-steel tread compound is as follows:

[0059] Considering that the viscosity of the final mixing rubber can meet the extrusion process, the rubber material is divided into four stages of mixing.

[0060] Weigh each component according to the metering point;

[0061] One-stage mixing: Add cis-1,4-polyisoprene rubber, neodymium-based high-cis-polybutadiene rubber, V9H carbon black, anti-aging agent, protective wax, stearic acid, nano Zinc oxide, internal mixer speed 40-60rpm / min, pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com