Tetramethylthiuram disulfide pre-dispersed mother colloidal particle and preparation method thereof

A technology of tetramethylthiuram disulfide and tetramethylthiuram disulfide powder, which is applied in the field of tetramethylthiuram disulfide pre-dispersed masterbatch and preparation, and can solve the problem of easy agglomeration and flying , Difficult to disperse and other issues, to achieve the effect of ensuring activity, weakening static electricity, and reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

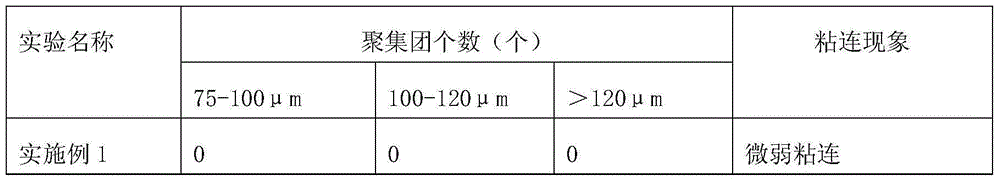

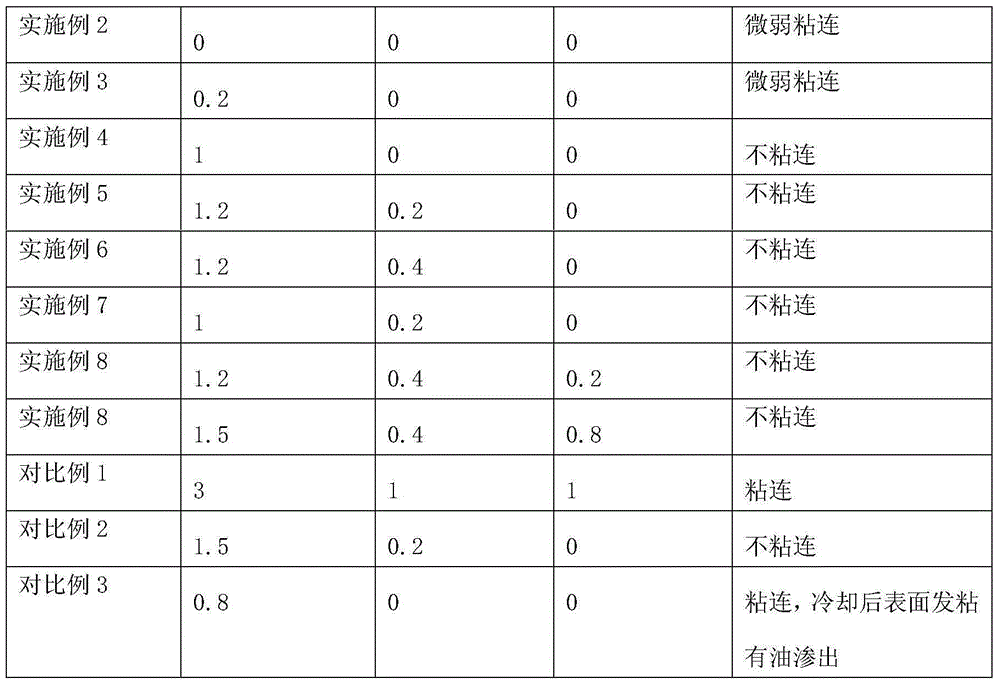

Embodiment 1

[0034] A kind of tetramethyl thiuram disulfide pre-dispersed masterbatch particles, comprising the following raw materials in parts by weight: 70 parts of tetramethyl thiuram disulfide powder, 10 parts of binary ethylene propylene rubber, 10 parts of ternary ethylene propylene rubber 5 parts, 5 parts of dispersant HST, 5 parts of paraffin oil.

[0035] The preparation method is as follows:

[0036] (1) Put the EPDM rubber and EPDM rubber into the internal mixer and mix for 30 seconds, then put in tetramethylthiuram disulfide powder, dispersant, paraffin oil and mix for 100 seconds, then lift the compact Turn over the top bolt on the mill once, then continue to mix with the ram, the total mixing time reaches 300 seconds, and the glue is discharged; the temperature of glue removal is 80°C; then, it is thinly passed on the mill for 3 times to obtain the masterbatch;

[0037] (2) Put the mixed masterbatch into an extruder equipped with an 80-mesh stainless steel filter screen for...

Embodiment 2

[0039] A kind of tetramethylthiuram disulfide pre-dispersed masterbatch particles, comprising the following raw materials by weight: 74 parts of tetramethylthiuram disulfide powder, 8 parts of binary ethylene propylene rubber, 8 parts of ternary ethylene propylene rubber 5 parts, 5 parts of dispersant HST, 5 parts of paraffin oil.

[0040] The preparation method is the same as in Example 1.

Embodiment 3

[0042] A kind of tetramethylthiuram disulfide pre-dispersed masterbatch particles, comprising the following raw materials by weight: 76 parts of tetramethylthiuram disulfide powder, 8 parts of binary ethylene propylene rubber, 8 parts of ternary ethylene propylene rubber 4 parts, 4 parts of dispersant HST, 4 parts of paraffin oil.

[0043] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com