Composite material for repairing road cracks and preparation method thereof

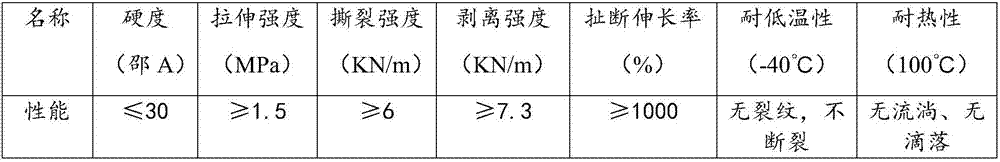

A composite material and crack technology, which is used in the field of composite materials for repairing road cracks and their preparation, can solve the problems of poor road adhesion, road crack protrusions, and low elongation at break, etc., and achieves strong adhesion and initial viscosity. Low, extended useful life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A composite material for repairing road cracks in this embodiment includes two components A and B, and the mass ratio of the two components A and B is 1:1;

[0049] The A component consists of the following raw materials in parts by mass:

[0050] Polyoxypropylene glycol N220: 30 parts;

[0051] Polyoxypropylene diol N210: 40 parts;

[0052] Amino-terminated polyoxypropylene ether D2000: 12 parts;

[0053] Pigment carbon black with particle size ≤ 5 μm: 8 parts;

[0054] Rutile titanium dioxide with a particle size of ≤10 μm: 7 parts;

[0055] Organic bismuth (KRBi-A3 organic bismuth produced by Changzhou Kairui Chemical Technology Co., Ltd.): 3 parts;

[0056] The B component consists of the following raw materials in parts by mass:

[0057] Polyether polyurethane prepolymer: 71.4 parts;

[0058] Bis(2-ethylhexyl) phthalate: 6 parts;

[0059] Dioctyl phthalate: 22.6 parts.

[0060] A method for preparing the composite material for repairing road cracks describe...

Embodiment 2

[0067] A composite material for repairing road cracks in this embodiment includes two components A and B, and the mass ratio of the two components A and B is 1:1;

[0068] The A component consists of the following raw materials in parts by mass:

[0069] Polyoxypropylene glycol N220: 65 parts;

[0070] Polyoxypropylene glycol N210: 25 parts;

[0071] Amino-terminated polyoxypropylene ether D2000: 5 parts;

[0072] Pigment carbon black with a particle size of ≤5 μm: 2 parts;

[0073] Rutile titanium dioxide with a particle size of ≤10 μm: 2 parts;

[0074] Organic bismuth (KRBi-A3 organic bismuth produced by Changzhou Kairui Chemical Technology Co., Ltd.): 1 part;

[0075] The B component consists of the following raw materials in parts by mass:

[0076] Polyether polyurethane prepolymer: 71.4 parts;

[0077] Bis(2-ethylhexyl) phthalate: 22.6 parts;

[0078] Dioctyl phthalate: 6 parts.

[0079] A method for preparing the composite material for repairing road cracks desc...

Embodiment 3

[0086] A composite material for repairing road cracks in this embodiment includes two components A and B, and the mass ratio of the two components A and B is 1:1;

[0087] The A component consists of the following raw materials in parts by mass:

[0088] Polyoxypropylene glycol N220: 37 parts;

[0089] Polyoxypropylene glycol N210: 38 parts;

[0090] Amino-terminated polyoxypropylene ether D2000: 11 parts;

[0091] Pigment carbon black with particle size ≤ 5 μm: 6 parts;

[0092] Rutile titanium dioxide with particle size ≤ 10 μm: 6 parts;

[0093] Organic bismuth (KRBi-A3 organic bismuth produced by Changzhou Kairui Chemical Technology Co., Ltd.): 2 parts;

[0094] The B component consists of the following raw materials in parts by mass:

[0095] Polyether polyurethane prepolymer: 71.4 parts;

[0096] Bis(2-ethylhexyl) phthalate: 10 parts;

[0097] Dioctyl phthalate: 18.6 parts.

[0098] A method for preparing the composite material for repairing road cracks described...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com