Salient point non-woven fabric production device

A production device and non-woven fabric technology, applied in the field of design textiles, can solve problems such as difficulty in using slurry coating, and achieve the effects of fast production speed, simple operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

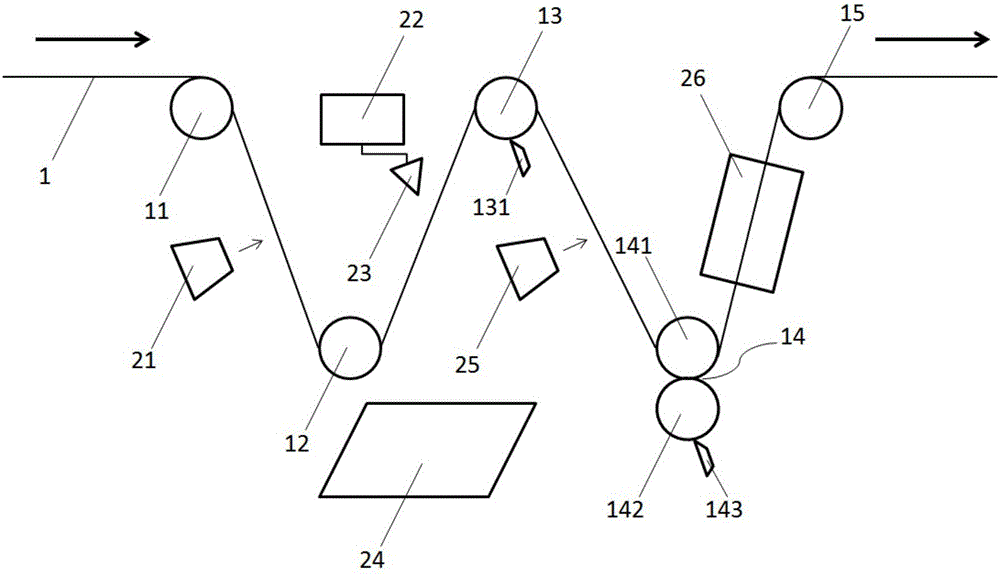

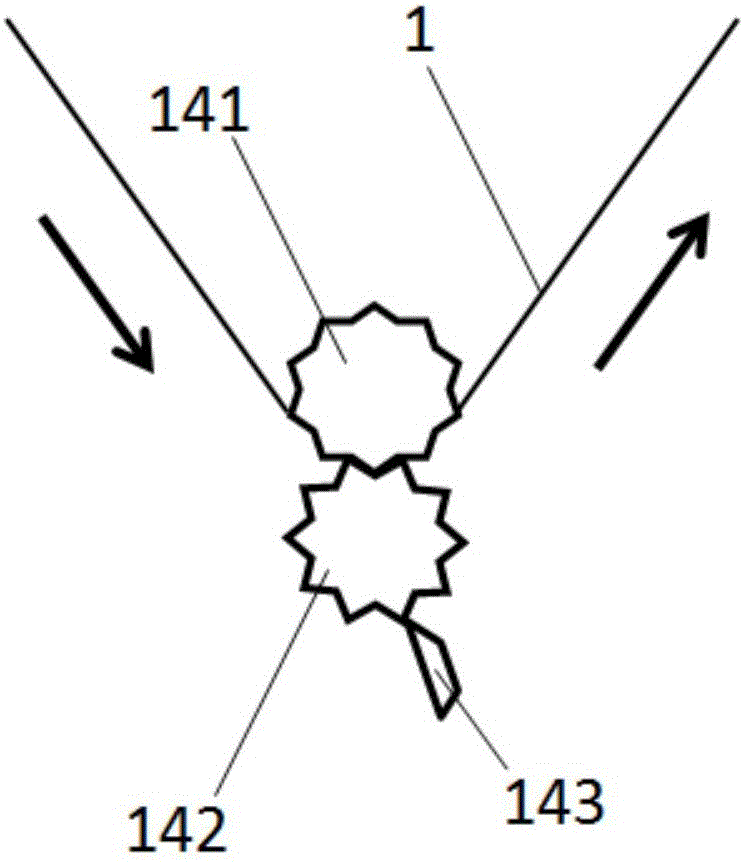

[0020] Such as figure 1 and image 3 As shown, the raised point nonwoven fabric production device of the present invention comprises the first cloth guide roller 11, the second cloth guide roller 12, the third cloth guide roller 13, the raised point roll group 14, the fourth cloth guide roller set in W shape in sequence. Cloth guide roller 15, the first cloth guide 11 and the second cloth guide roller 12 are provided with the first hot air blower 21, the second cloth guide roller 12 and the third cloth guide roller 13 are provided with spraying device, the third cloth guide roller A second hot air blower 25 is arranged between the cloth roller 13 and the bump roller group 14, a dryer 25 is arranged between the bump roller group 14 and the fourth cloth guide roller 15, and the bump roller group 14 includes metal bumps. On the convex roller 141 and the concave roller 142 with metal concave points, the soft plastic material squeegee 131 is arranged under the cloth guide roller 1...

Embodiment 2

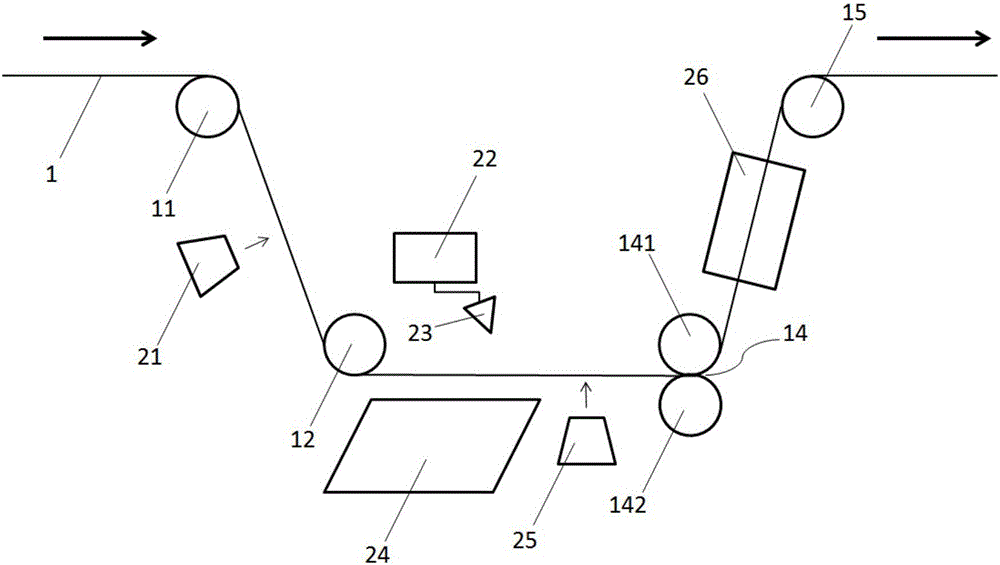

[0023] Such as figure 2 and image 3 As shown, the raised point non-woven fabric production device of the present invention comprises the first cloth guide roller 11, the second cloth guide roller 12, the raised point roll group 14, the fourth cloth guide roller 15 arranged in sequence, the first cloth guide roller 11 and the second cloth guide roller 12 are provided with a first hot air blower 21, and between the second cloth guide roller 12 and the bump roll group 14 are provided with a spray device and a second hot air blower 25, and the bump roll group 14 and the first bump roll group A dryer 25 is arranged between the four cloth guide rollers 15, and the bump roller group 14 includes a convex roller 141 provided with metal bumps and a rubber concave roller 142, and a soft plastic scraper is arranged under the cloth guide roller 13 131 scrapes off redundant slurry, and gravure roller 142 below is provided with desizing brush 143 and brushes off the slurry that is stained...

Embodiment 3

[0026] Such as figure 1 and Figure 4 As shown, the raised point nonwoven fabric production device of the present invention comprises the first cloth guide roller 11, the second cloth guide roller 12, the third cloth guide roller 13, the raised point roll group 14, the fourth cloth guide roller set in W shape in sequence. Cloth guide roller 15, the first cloth guide 11 and the second cloth guide roller 12 are provided with the first hot air blower 21, the second cloth guide roller 12 and the third cloth guide roller 13 are provided with spraying device, the third cloth guide roller A second hot air blower 25 is arranged between the cloth roller 13 and the bump roller group 14, a dryer 25 is arranged between the bump roller group 14 and the fourth cloth guide roller 15, and the bump roller group 14 includes metal bumps. On the convex roller 141 and the concave roller 142 with metal concave points, the soft plastic material squeegee 131 is arranged under the cloth guide roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com