Multifunctional decontaminating column used for detecting alternaria spp toxin and use method thereof

A multifunctional purification column and Alternaria technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of poor detection and purification effect of Alternaria toxin, complicated reagents, and inability to detect, and achieves convenient and economical pretreatment. Time and cost, effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: raw material and preparation of multifunctional purification column

[0042] 1. Raw materials:

[0043] (1) Column tube: 6mL polypropylene or glass column tube with an inner diameter of 12.7mm;

[0044] (2) Sieve plate: polyethylene or polytetrafluoroethylene sieve plate with a pore size of 10-30 μm;

[0045] (3) Reverse-phase chromatography filler: 200 μL particle size of 40-60 μm reverse-phase chromatography filler HLB;

[0046] (4) Cation exchange chromatography filler: 200 μL of cation exchange chromatography filler MCX with a particle size of 40-60 μm.

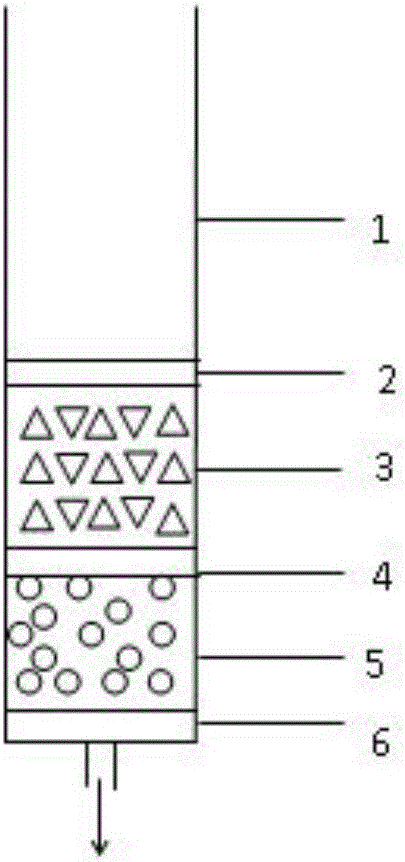

[0047] 2. Assembly method (see attached figure 1 )

[0048]to polypropylene or glass column tubes (attached figure 1 In step 1), first fill a piece of sieve plate (attached figure 1 6) in , add 200μL cation exchange chromatography filler (attached figure 1 5) in, and then fill in the second sieve plate (attached figure 1 4) in , add 200 μL of reversed-phase chromatography filler (attached fig...

Embodiment 2

[0049] Embodiment 2: raw material and preparation of multifunctional purification column

[0050] 1. Raw materials

[0051] (1) Column tube: 6mL polypropylene or glass column tube with an inner diameter of 12.7mm;

[0052] (2) Sieve plate: polyethylene or polytetrafluoroethylene sieve plate with a pore size of 10-30 microns;

[0053] (3) Reverse-phase chromatography filler: 600 μL particle size of 40-60 μm reverse-phase chromatography filler HLB;

[0054] (4) Cation exchange chromatography filler: 200 μL of cation exchange chromatography filler MCX with a particle size of 40-60 μm.

[0055] 2. Assembly method

[0056] Fill a polypropylene or glass column tube with a sieve first, add 200 μL of cation exchange chromatography packing material, then fill in the second sieve plate, add 600 μL reverse phase chromatography packing material, then fill in the third sieve plate, and press tightly.

Embodiment 3

[0057] Embodiment 3: raw material and preparation of multifunctional purification column

[0058] 1. Raw materials

[0059] (1) Column tube: 6mL polypropylene or glass column tube with an inner diameter of 12.7mm;

[0060] (2) Sieve plate: polyethylene or polytetrafluoroethylene sieve plate with a pore size of 10-30 microns;

[0061] (3) Reverse-phase chromatographic filler: 600 μL particle size of 40-60 μm reverse-phase chromatographic filler;

[0062] (4) Cation exchange chromatography filler: 600 μL of cation exchange chromatography filler with a particle size of 40-60 μm;

[0063] 2. Assembly method

[0064] Fill a polypropylene or glass column tube with a sieve first, add 600 μL of cation exchange chromatography packing material, then fill in the second sieve plate, add 600 μL reverse phase chromatography packing material, then fill in the third sieve plate, and press it tightly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com