A method for making a PCB with multiple surface treatments

A surface treatment and production method technology, which is applied in the secondary treatment of printed circuits, printed circuit manufacturing, cleaning/polishing of conductive patterns, etc., can solve the problems of single processing methods, avoid mutual interference, prevent copper plating, The effect of increasing binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

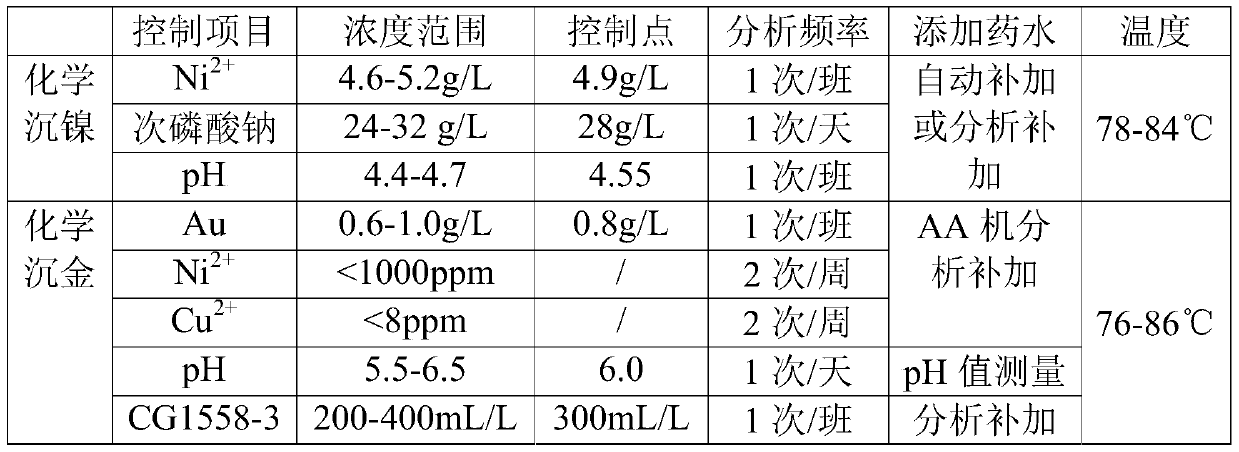

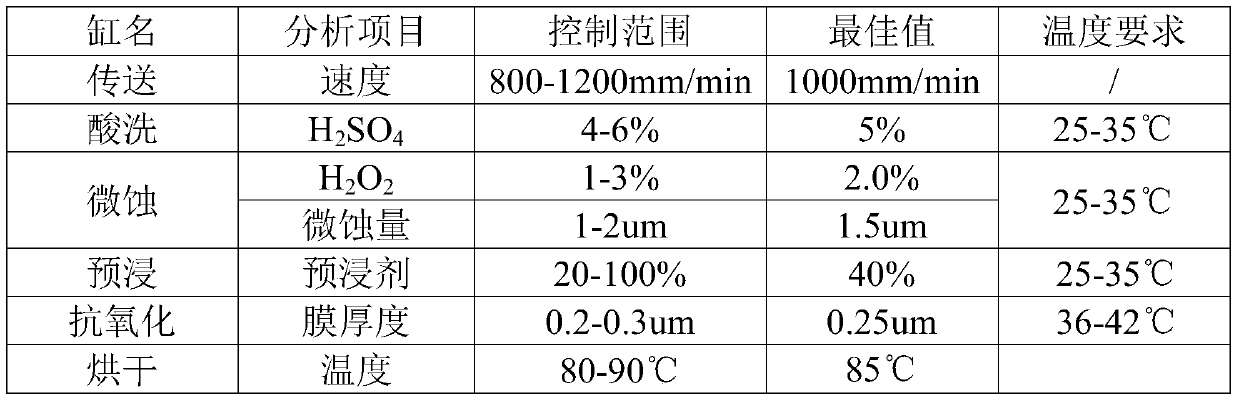

[0023] This embodiment provides a method for manufacturing a PCB with multiple surface treatments. The PCB is provided with an electric gold position, a nickel-immersion gold position, and an anti-oxidation position. The gold position is treated with immersion nickel gold surface treatment, and the anti-oxidation position is treated with anti-oxidation surface treatment.

[0024] The specifications of the PCB are as follows: completed board thickness: 1.6mm; completed minimum aperture: 0.25mm; diameter-to-thickness ratio: 8:1; bottom copper thickness: 0.5OZ; partial thick gold PAD (electrical gold position) gold thickness > 0.76um; Local immersion gold PAD (immersion nickel gold position) gold thickness > 0.05um; anti-oxidation film thickness (anti-oxidation position): 0.2-0.3um; minimum line width / spacing: 0.12 / 0.12mm.

[0025] The manufacturing method of the PCB comprises the following steps:

[0026] (1) Making multi-layer boards

[0027] According to the prior art, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com